This article is part of the TechXchange: Delving into EMI, EMC and Noise.

What you’ll learn:

- How the influx of sensors in today’s connected vehicles makes links more susceptible to EMI.

- The limitations of current approaches to EMI.

- Why a digital connectivity standard is vital to the future of ADAS and infotainment systems.

In early 1979, Ralph Liuzzi installed a mobile transmitter in his customer’s Cadillac Seville. However, Mr. Liuzzi found that whenever he attempted to transmit, the car’s engine would stall, resulting in a serious safety hazard for both driver and pedestrians.

At the time, the National Highway Traffic Safety Administration (NHTSA) cited a “lack of documentation on the effects of Electromagnetic Interference (EMI) on automobile electronic engine control systems,” but reviewed the case and eventually found that indeed EMI played a key role in the system malfunction. “The problem of EMI is a relatively new one in automotive technology since electronics have only recently been introduced into usage in automobiles,” the NHTSA said in its report.

Now, more than 40 years later, the problem of EMI has only grown. As recently as 2020, more than 2.8 million vehicles were recalled by a single OEM due to an electronic control unit (ECU) having inadequate protection against certain electrical noise, which could lead to incomplete or nondeployment of the airbags in the case of a crash.

The NHTSA has since investigated airbags installed in more than 12 million cars, all equipped with the airbag control unit that could fail to deploy due to EMI. The investigation has led to further recalls of more than 2 million additional vehicles from various OEMs.

The electrification of today’s connected vehicles has resulted in more sources of EMI in the modern car, coming from both inside and outside the car. This interference can lead to the degradation or corruption of signals, which are distributed via various connectivity solutions, and can lead to critical sensor and advanced driver-assistance system (ADAS) failures.

Legacy Limitations

EMI will affect components all around the vehicle, but the most susceptible are the links—wires connecting sensors to ECUs, ECUs to ECUs, and more. Current in-vehicle connectivity solutions that utilize legacy technologies have traditionally diminished the effects of electronic noise by reducing bandwidth, limiting cable length, increasing frequency, and adding expensive shielding to cables.

OEMs have worked hard to protect these links from EMI, but reviewing these methods reveals that they’re not optimal:

- Shielded cables: Shielding has long been considered a key solution to guard against EMI, but there’s a growing understanding within the industry that shielding degrades over time and stress, leaving links susceptible to interference. The problem is particularly acute in dynamic installations, such as doors, side mirrors, and trunk lids.

- Forward error correction (FEC): Used to identify and rectify errors caused by EMI, FEC can be very effective in certain restricted noise categories, such as constant and consistent low amplitudes or additive Gaussian white noise (AGWN). However, the harsh automotive environment includes many common noise classifications that FEC proves ineffective against, such as narrowband interference (NBI), alien crosstalk (Xtalk), and transients on line (TOL).

- Limiting cable length: Restricting cable length is an effective solution to EMI. But the drawback is that it limits the flexibility of in-car architectures, forcing the placement of ECUs in sub-optimal locations within the vehicle. This hampers the industry’s advance toward zonal and centralized E/E architectures, where increasing cable length is becoming necessary.

- Reducing bandwidth: One of the easiest and most effective ways to mitigate EMI is to reduce bandwidth, but the industry is moving in the opposite direction. Bandwidth demands will only continue to grow amid the shift toward sensor fusion, centralized processing, and software-defined vehicle (SDV) features, all of which require innovations in cameras, radar, LiDAR, and more powerful ECUs.

These existing solutions impose limitations on in-vehicle connectivity infrastructure. They also erect significant barriers to deploying next-generation vehicles on the road.

EMI Meets MIPI

To address these challenges, automakers must adopt a digital connectivity standard. One of the leading candidates is the MIPI A-PHY standard for in-vehicle connectivity.

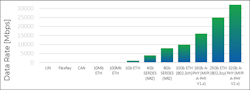

The EMC performance of MIPI A-PHY is unprecedented in the industry, with chipsets able to reach a Packet Error Rate of 10-19—orders of magnitude better than existing solutions on the market (see figure). Such large margins are important as the problem of EMI worsens over time. The latest innovations in ADAS and infotainment systems demand ever-increasing bandwidths, inevitably leaving links more susceptible to interference.

MIPI A-PHY addresses EMI with a DSP-based approach that includes mechanisms such as just-in-time noise cancellation (JITNC) and dynamically modulated PHY level retransmission:

- Just-in-time noise cancellation: JITNC is a fast and adaptive way of removing noise to reduce the effects of EMI, and it’s particularly good at handling NBI, the sharp and sudden noises that legacy in-vehicle connectivity solutions find difficult to deal with.

- Dynamic PHY level retransmission: There are occasions when the environment suffers from so much noise that data packets can fail due to interference. When this occurs, the MIPI A-PHY standard calls for retransmission of the data packet using a lower pulse-amplitude modulation (PAM) than what was originally sent, which decreases the chances of the transmission failing again.

Due to its EMI resilience, a large ecosystem is emerging to back the MIPI A-PHY standard for in-vehicle sensor connectivity. Everyone from leading Tier-1 suppliers such as Aptiv and Denso; camera and sensor manufacturers such as Leopard Imaging, Sony, and Sunny Optical; Mobileye and other chip companies; system-in-package (SiP) vendors such as LG Innotek; connector and cable manufacturers such as Hosiden and Sumitomo; and foundries like Intel are all lining up behind it. Other backers include EDA companies such as Cadence Design Systems and test equipment experts like Keysight.

These companies recognize the growing importance of electromagnetic compatibility (EMC), as higher bandwidth systems continue to be integrated into next-generation cars.

The Road Ahead

The effect of EMI has led to severe consequences in critical systems in the past and will only prove a greater challenge in the future. With more safety-critical high-bandwidth links than ever before, the modern vehicle is becoming increasingly vulnerable to EMI attacks. To address these challenges and ensure link integrity over a vehicle’s lifespan, the industry is at a stage where it needs to take digital connectivity standards like A-PHY more seriously.

Limiting the consequences of EMI in every area should be one of the industry’s top priorities. OEMs that fail to properly address this issue will find themselves unable to facilitate the latest innovations in ADAS, V2X communications, infotainment, and other areas, into their offerings.

Read more articles in the TechXchange: Delving into EMI, EMC and Noise.