Members can download this article in PDF format.

Today’s software-defined vehicles (SDVs) enable automakers to offer unprecedented levels of service, personalization, and convenience. But the hundreds of electronic components that populate these vehicles demand new approaches to vehicle networking and connectivity.

Sponsored Resources:

- Seamless connectivity for vehicle networking

- Explore automotive communication trends

- Communication protocols in modern ADAS architectures

Traditional Buses: Ethernet, CAN, LIN

Established communications technologies such as Ethernet, Controller Area Network (CAN), and Local Interconnect Network (LIN) will continue to find use in connecting electronic control units (ECUs) to sensors and actuators within modern vehicles. For example, ultra-low-latency Ethernet devices can enable high-bandwidth communications.

One such device is Texas Instruments’ DP83TG720S-Q1 1000BASE-T1 Ethernet transceiver (Fig. 1). It provides the physical-layer functions necessary to transmit and receive data at 1 Gb/s over single unshielded/shielded twisted-pair cables.

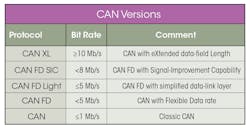

In contrast, CAN and LIN, with lower costs per node than Ethernet, remain cost-effective for low-bandwidth functions, such as window control. LIN, a single-wire commander-responder bus, operates at speeds up to 20 kb/s. CAN, a multi-commander serial bus, comes in several variations (see table). It ranges from original CAN, which carries an eight-byte payload and operates at data rates to 1 Mb/s, to CAN XL, which carries a 2-kB payload and operates at 10 Mb/s or more, overlapping low-end Ethernet.

Zonal Architecture Reduces Cabling, Weight, and Cost

Ethernet, CAN, LIN, and other data links will have to work together seamlessly in forthcoming automotive network architectures. Automakers have traditionally employed domain architectures, which group a vehicle’s ECUs according to function.

Today, though, domain architectures are giving way to zone architectures that group ECUs by location. One ECU in each zone communicates with other zones or a centralized processor over a high-speed link such as Ethernet, while buses like LIN and CAN handle communications within each zone. Zone architectures reduce cabling complexity as well as weight and cost while also effectively handling the increasing amount of data that keeps the SDV running.

Texas Instruments is well positioned to address the communication challenges that this shift to zone architectures imposes, according to Tsedeniya Abraham, vice president of interface products at the company. “We can help designers manage and simplify the mix of data types that a zone architecture calls for. While Ethernet between the zone control modules is the best choice for high-speed data transmission, CAN or LIN are efficient, fast choices for the last mile of communication within each zone.”

FPD-Link for Video

In addition to Ethernet, CAN, and LIN, interfaces such as Flat-panel display (FPD)-Link and the Peripheral Component Interconnect Express (PCIe) also have roles to play in vehicle connectivity. FPD-Link is a proprietary serial-deserializer (SerDes) technology that can transmit real-time, uncompressed, high-bandwidth video data from a camera to a display or processor (Fig. 2).

Unlike Ethernet, which can carry video data over a shared link, FPD-Link provides a dedicated twisted-pair or coaxial-cable physical layer for each attached camera. Thus, video quality is independent of other data transmissions throughout the vehicle.

FPD-Link has a forward-channel bandwidth of 25 Gb/s or more and a low-speed back channel that controls general-purpose I/O lines at rates up to 1 Mb/s. The back channel can be used to configure a camera, control a zoom lens, or send touchscreen information to a controller without interfering with video data flow on the forward channel.

Because FPD-Link carries uncompressed video data, it eliminates the need for compression and decompression, thereby simplifying the circuitry required for the camera and display. It also eliminates the latency involved in compression and decompression processing, helping to meet the low latencies required for safety-critical applications such as collision avoidance.

PCIe Takes on Automotive Apps

PCIe has typically found use in personal and industrial computers as well as servers and other computing equipment to connect motherboards to peripherals such as graphics cards. However, it shows promise for automotive applications as well. Because PCIe can connect one central processing unit to multiple end points, it’s able to carry data between a centralized processor and zone ECUs, potentially offloading processing tasks from the zone ECUs and reducing the number required.

Because PCIe’s throughput tends to double with each successive generation, it shows promise for keeping up with growth in automotive bandwidth requirements. PCIe is a serial interface that supports up to 32 lanes. The current version, PCIe 5.0, offers a per-lane transfer rate of 32 Gtransfers/s, up from 16 Gtransfers/s for PCIe 4.0. The next version, PCIe 6.0, whose spec was released in 2022, boasts 64-Gtransfers/s per lane.

PCIe offers other advantages, too. Many processors have a native PCIe interface built in, so automotive engineers will not need to add protocol-translation circuitry. Furthermore, PCIe is supported by a large software ecosystem that can be leveraged by the automotive industry.

Wireless Networking: From Monitoring to Vehicle Access

Wireless technology also finds use in vehicle connectivity, extending from tire pressure monitoring to vehicle access. Today, drivers commonly use key fobs to unlock cars, although the fob approach isn’t particularly secure, according to Evan Wakefield, application manager from TI’s wireless connectivity automotive team. An alternative is to unlock a vehicle using a cellphone.

“You can pair with your car through Bluetooth Low Energy and use either ultra-wideband today or, in the future, channel sounding, which is a new feature coming in a future Bluetooth core spec,” explained Wakefield, adding that channel sounding will enable reliable, secure, and accurate distance measurements using a single Bluetooth radio.

Electric-vehicle battery-management systems (BMS) present another potential opportunity for an automotive wireless application. Wakefield said an effort is underway to investigate how wireless technology could improve BMS performance and reliability while reducing weight by minimizing the required number of cables and electromechanical connectors.

Conclusion

Automotive connectivity strategies are evolving as automakers contend with the rapidly increasing amounts of data being exchanged between sensors, actuators, ECUs, and centralized processors. TI is well positioned to assist you in designing wired and wireless networks, offering a full line of interface products as well as the design resources necessary to ensure your success.

Sponsored Resources: