Members can download this article in PDF format.

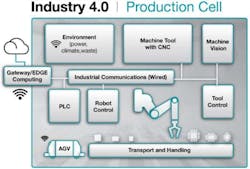

Networking is the connective tissue of the modern factory, with networking architecture unlocking better efficiency, safety, and sustainability via improvements in predictive maintenance and Ethernet efficiency. All of this aims to transform factories to meet the digitization and connectivity needs of Industry 4.0, which focuses on tying together information technology with operational technologies so that manufacturing systems can become smarter and more autonomous (Fig. 1).

Resources

With more sensors and higher-level processing capabilities such as edge artificial intelligence (AI), these systems need to have extremely reliable real-time communications. That means communicating messages with minimal latency (time delay between message sent and message received) and jitter (the variance of the latency).

As networked intelligence spreads to the factory floor, manufacturers are improving production through advances in both connectivity and digitization (Fig. 2).

Solving the Tradeoffs Between Speed and Reliability

Delays are unacceptable in control systems such as those in production lines. Even something as simple as a few milliseconds of unexpected delay in the delivery of a control signal could cause permanent damage. In a worst-case scenario, a dropped connection might lead to situations such as a robot arm running dangerously out of control.

Furthermore, communications, industrial automation, and control system networks must have sufficient electrical noise immunity to operate reliably around high-energy devices such as welders.

For these reasons, factories have traditionally relied on communications technologies with deterministic communication, guaranteeing the delivery of all control signals within a set time period. The downside presented by most of these technologies, however, is their slow speed. It prevents the kind of fast and high-volume information flow needed to benefit from intelligently controlled systems.

Ethernet has long provided the bandwidth required for advanced automation. EtherCAT and Profinet are examples of industrial Ethernet protocols designed specifically to address the challenges of industrial environments.

Adopting Ethernet for Industrial Control and the Advent of SPE

While these protocols have made Ethernet fit for use in industrial control settings, installation costs have posed a hurdle to their adoption. Traditionally, Ethernet has been designed around multiple twisted-pair cables, with a maximum length of up to 100 meters.

This means that manufacturers looking to adopt Ethernet would not only need to replace all of their cabling, but it would potentially have to change the entire layout of a factory built around older, single-pair technologies that permitted cable lengths of up to a few kilometers.

Shutting a factory down for maintenance is costly, but the deployment of predictive analytics can automatically anticipate when maintenance or repair work will be needed. Using predictive maintenance means you can perform maintenance work only as and when it’s needed, avoiding unnecessary downtime and waste.

Development of single-pair Ethernet (SPE)—the transmission of Ethernet over only one pair of copper wires, which can operate over a factory’s existing cables—has been a key advance supporting Ethernet adoption. SPE eliminates the need to fundamentally change how you build a manufacturing facility.

Embedded processors, from microcontrollers to microprocessors, play a crucial role in the transition to Ethernet-based communications by helping manage the growing amount of data between connected systems and ensuring interoperability across network protocols. In industrial communication designs, embedded processors ensure reliable communications between systems. They also have the potential to do more, especially in terms of predictive maintenance and system monitoring.

Texas Instruments’ semiconductor device portfolio ranges from cost-effective microcontrollers to high-performance Arm Cortex-A72x-based systems-on-chips (SoCs). These devices help designers better manage their transition to Ethernet by supporting a variety of fieldbus protocols, as well as industrial Ethernet protocols at speeds as high as 1 Gb/s.

Time-Sensitive Networks

Time-sensitive-networking (TSN) technology guarantees delivery and minimized jitter using time scheduling for real-time applications that require determinism (Fig. 3). TSN delivers functionality for device clock synchronization, traffic prioritization, and traffic shaping.

The development of TSN standards make Ethernet well-suited to guaranteed delivery within a specified time window. These features enable devices to coordinate their communication schedules.

TSN uses redundancy to guarantee latency even in the presence of failures such as cut cables or broken switches. It’s a set of roughly 12 IEEE 802 standards, all of which are included in IEEE 802.1Q-2018.

Building an Advanced Factory Floor

No matter what Industry protocol you're using, TI has the portfolio and resources to support it. As a member of the Ethernet Alliance, for example, the company is committed to aiding in development of industrial Ethernet’s many forms through its range of physical-layer transceivers that support single-pair, multipair or fiber cabling.

TI’s processors and MCUs can help you realize the industrial communication subsystems needed for Industry 4.0, safely and securely integrating these systems into the broader manufacturing environment.

Resources