Members can download this article in PDF format.

Unless you’ve spent the past couple of years isolated in a cave, and possibly even then, you know that one of the most promising technologies in the designer’s toolkit these days is gallium nitride (GaN). The wide-bandgap semiconductor is employed in a growing list of use cases, such as consumer electronics, automotive, and industrial applications.

GaN field-effect transistors (FETs) exhibit a lower on-state resistance compared to silicon-based FETs, which have long dominated these markets. This reduced resistance decreases power loss during operation, significantly increasing efficiency and minimizing the need for added cooling components. GaN offers zero reverse-recovery losses, with the lowest overall switching energy loss—over 50% lower versus comparable SiC MOSFETs.

GaN FETs provide power supplies with greater power density and energy efficiency, higher switching frequencies, better thermal management, and smaller sizes than traditional silicon metal-oxide semiconductor FETs (MOSFETs) and insulated gate bipolar transistors (IGBTs).

Faster FETs

Thanks to the higher electron mobility of GaN FETs, TI’s new LMG3622, LMG3624, and LMG3626 enable faster switching speeds, which helps keep adapters from overheating. An integrated gate driver reduces component count and simplifies design.

These FETs also allow for a higher current density, contributing to the development of smaller, yet more efficient, power supplies. Designs can reach up to 94% system efficiency for <75-W AC-DC applications or above 95% system efficiency for >75-W AC-DC apps.

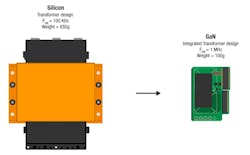

With a majority of electronics moving to USB Type-C chargers, demand is on the rise for compact power adapters that can charge all of a consumer’s devices. The new GaN FET devices can help designers reduce the solution size of a typical 67-W power adapter by as much as 50% compared to silicon-based solutions (Fig. 1).

Integrated Current Sensing

Converters generally require some form of system-level current sensing for control, protection, or both. Analyzing a system’s current level can diagnose unintended or unexpected operating modes, allowing for adjustments to be made to improve reliability or protect the system components from damage.

The converter must be able to effectively shut down and avoid thermal runaway or permanent damage in the event of a surge condition or electrical failure.

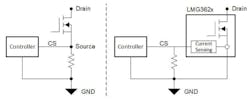

Applications that require current sensing have traditionally used a series shunt resistor between the source of the switching device and the system ground. This traditional current-sensing method is undesirable as it requires a physically large sensing resistor (RCS(trad)) that dissipates significant power, adding unwanted heat to the system and reducing the overall efficiency.

In addition, with this sensing method, the source of the device is separated from the system ground. Thus, it’s difficult to connect the thermal pad to a large ground plane, which is desirable for better thermal dissipation.

With the new family of GaN FETs, TI said it offers the industry’s most accurate integrated current sensing. All three members of the series include built-in current sensing that continuously outputs a real-time replica of the positive-going drain to the source device current.

This feature replaces traditional shunt resistors without tradeoffs or inaccuracies, improves system efficiency and thermal performance, and reduces associated power losses by as much as 94% when compared to traditional current-sensing circuits used with discrete GaN and silicon FETs (Fig. 2).

The parts support converter light-load efficiency requirements and burst-mode operation with low quiescent currents and fast startup times. Protection features include undervoltage lockout (UVLO), cycle-by-cycle current limit, and overtemperature protection.

GAN FETs Promote Smaller, Lighter Solutions

The challenge in designing modern consumer USB Type-C mobile chargers, PC power supplies, and TV power supplies is shrinking solution size while maintaining or increasing the power level.

TI’s low-power GaN devices help address this problem in a wide variety of the most popular topologies while simultaneously offering thermal and integration benefits. With the new TI family, engineers can develop AC-DC solutions that are half the size and achieve >95% system efficiency, simplifying thermal design.

As GaN-based power-supply designs continue to become more prevalent due to their efficiency and size benefits, the integration and feature set provided by TI’s GaN solutions enable system improvements such as reduced BOM count and board area along with better thermal management.

With the expansion of TI’s portfolio, designers can bring the power-density benefits of low-power GaN technology to more applications that consumers use every day, such as mobile-phone and laptop adapters, TV power-supply units, and USB wall outlets.

Conclusion

The crucial question is, if given a choice, would engineers trade the traditional silicon-based FET power circuits for the superior efficiency, minimized form factors, and heightened power density of GaN circuits? This article has presented the case that it would be in the affirmative.

Production quantities of the LMG3622 and LMG3626 and pre-production quantities of the LMG3624 are available for purchase now.