What you’ll learn:

- What is elastic-wave touch-sensing technology and how easily can it be applied?

- Key markets benefiting from the technology, such as automotive, computing, and wearables.

“Elastic wave” is based on the generation and propagation of mechanical waves within rigid objects like glass, wood, or plastic. These waves are triggered by contact events, for example by pressing or tapping on the object's surface. When particles in the medium are displaced, a force proportional to the displacement works to return them to their original positions, resulting in motion.

This displacement initiates the motion of adjacent particles, leading to the propagation of stress or strain throughout the medium at a visible scale. Elastic-wave sensors are designed to detect the signals of these elastic waves, which are essentially vibrations caused by contact and deformation. Such sensors leverage various frequencies, utilizing different propagation speeds. Consequently, they offer a broad bandwidth, theoretically spanning from 0 to over 100 MHz.

What Makes Elastic Wave Work?

Elastic wave presents a highly complicated mechanical phenomenon. Elastic-wave solutions exemplify this complexity by conducting extensive experiments and employing machine-learning (ML) techniques to establish a comprehensive model. This model is then integrated into a database, encompassing diverse waveform characteristics derived from various materials or structures.

The model is tasked with multiple objectives, including identifying the precise location (positioning), intensity (force), and nature of touch events (such as the magnitude and duration of contact with an object). Such an identification process involves signal capture, signal processing, and analysis, along with specialized ML algorithms.

Elastic-wave touch sensing is a comprehensive approach that combines highly sensitive application-specific integrated circuits (ASICs) and algorithms. The machine's surface utilizes this technology to sense and recognize touches, collisions, and forms of contact.

As artificial-intelligence (AI) technology continues to advance, the demand grows for enhanced human-computer interaction experiences. The ultimate objective of interaction design is to realize human-centered interaction, striving for improved ergonomic and interactive experiences.

Force-Sensitive Touchpads

A significant milestone in this pursuit was marked in 2015 with the launch of the Apple MacBook Pro featuring the Force Touch Trackpad. Three years later, in 2018, this innovative technology found its way into Apple's entire lineup of notebooks. The incorporation of Force Touch into the company’s laptops sparked a race among other computer manufacturers to catch up.

Since the debut of the Force Touch Trackpad in these notebooks, various stakeholders within the technology ecosystem have relentlessly strived to keep pace. Notebook original equipment manufacturers (OEMs), touchpad integrators, and technology solution providers have dedicated years of effort to innovating and perfecting haptic touchpad technology.

The first application of this technology is in notebook computers. It’s used to enable force-sensitive touch control in Windows laptops, improving the interaction experience for users.

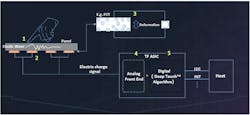

- Elastic-wave generation: When an object is touched, an elastic wave is generated within the panel (medium).

- Wave propagation and sensor interaction: The wave propagates through the panel until it reaches a sensor. The interaction between the wave and the sensor causes minor deformation in the sensor, often at nanometer levels.

- Signal generation: The deformed sensor generates electric-charge signals, which are then converted into voltage signals.

- Algorithmic analysis: An algorithm is employed to establish the fundamental relationship between the voltage signals and the deformation of the sensor.

- Touch force calculation: The material characteristic model, obtained beforehand, is combined with the algorithmic relationship. This enables the calculation of the actual touch force.

The first laptop to apply this technology was the Lonovo XiaoXin Pro 13s, which was launched in late 2019. Thanks to the use of this touch-sensing technology, the XiaoXin Pro13s offers a highly integrated C-surface design.

Seamless Haptic Touchpads Leveraging Elastic Wave

Haptic touchpad solutions, such as those developed by Taifang, capitalize on the unique attributes and benefits of elastic-wave force detection, resulting in an approach that offers both seamless type and Windowed types of solutions.

The seamless solution integrates four to six sensors along with a dedicated IC, forming the core hardware foundation. This setup is complemented by the incorporation of either an X or Y linear resonant actuator (LRA), or even unique Z-axis motors. These crucial components, along with the touch IC, are seamlessly connected to the PCB through traditional reflow soldering procedures, culminating in a fully functional module.

The final step involves coupling this module with a larger glass cover, creating the fundamental building block of the seamless haptic-pad module. Furthermore, an innovative light pad design is introduced to provide users with clear visual cues for touch area prompts during usage.

The innovation behind the seamless solution leverages elastic-wave force detection for a cohesive and advanced haptic-pad module. This holistic approach combines sensors, dedicated ICs, actuators, and creative design elements, leading up to an enhanced user experience that seamlessly integrates with the system.

Simultaneously, for traditionally designed laptops, the haptic pad utilizing elastic waves presents an opportunity to replace the conventional click pad. Making such a transition not only offers a more advanced solution, but also contributes to lighter and slimmer laptops.

In this solution, four force sensors are placed at the corners of the PCB, plus there’s a dedicated IC and either an LRA or an innovative voice coil motor (VCM). The outcome of this configuration is a haptic pad that uniformly detects force across its surface. In addition, the integration of crisp and distinct vibration feedback mechanisms further elevates the tactile experience for touch interactions.

Elastic Wave’s Advantages for Notebooks

Compared to traditional legacy trackpads, seamless haptic touchpads using the elastic-wave solution offer notebook users a significantly more accurate touch-sensing experience. Furthermore, these touchpads exhibit superior resistance to water, dust, contaminants, and other environmental factors.

By combining haptics and elastic-wave sensing, touchpads can be streamlined to an incredibly small size. This advance plays a crucial role in ushering in a new era of ultra-lightweight and ultra-thin notebook computers. The compact touch-sensing solution liberates additional space within the device, allowing for larger battery capacity and, consequently, longer battery life.

Leveraging the capabilities of an elastic-wave-based sensing solution, particularly with an LRA, contributes to the creation of a vibrational surface that users perceive as a distinct and precise click sensation. Moreover, the haptic feedback intensity of the sensing solution can be tailored to meet the user's specific application requirements, thereby placing enhanced controls at the user's fingertips.

Touch Sensing in Automotive Applications

Electrification and more intelligence are transforming the automotive sector. Introducing tactile perception capabilities into automobiles can significantly enhance the travel experience and elevate safety while driving.

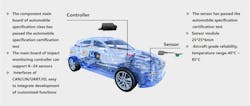

Automotive-specific touch sensing, such as the Taifang Automobile Impact Perception System (TAIPS) solution, has the potential to revolutionize the automotive industry by infusing vehicles with tactile perception capabilities. This advance aligns with the trends of electrification and increased intelligence in automobiles, ultimately contributing to safer, more interactive, and smarter vehicles.

In the automotive arena, traditional collision perception methods based on acceleration have faced persistent challenges. These include the inability to accurately detect subtle micro-collisions, as well as the issue of false triggering in non-collision scenarios. It’s led to difficulties in effectively monitoring and perceiving mild collisions.

TAIPS operates by strategically positioning elastic wave sensors on the internal "skin" of the vehicle. These sensors are designed to detect the propagation of elastic waves that occur when the vehicle's body comes in contact with external objects. By focusing on the characteristics of these elastic waves, TAIPS can accurately distinguish between different collision events, thereby mitigating the challenges associated with false triggering.

The versatile application of elastic-wave touch sensing offers a multitude of benefits and capabilities across various automotive scenarios:

- Collision avoidance in self-driving vehicles: For self-driving vehicles, especially when operating at low speeds, elastic-wave touch sensing can detect collisions and trigger urgent braking to prevent secondary collisions, thus helping to ensure the safety of pedestrians and avoiding further damage.

- Blind-spot collision prevention: During the initial stages of vehicle movement where blind spots are more prominent, the technology can enable emergency braking upon detecting a collision in the blind area. This proactive measure helps mitigate serious injuries and prevent subsequent collisions.

- Enhanced human-vehicle interaction: In scenarios where the vehicle is unlocked and not yet started, elastic-wave touch sensing can facilitate interactive functions. These include knock-knock gestures to activate features like charging port switches or other interactive commands, similar to the features seen in Tesla vehicles.

- Battery-chassis monitoring: This technology can enable all-weather monitoring of the battery chassis. In the case of mild collisions affecting the battery, the system can accurately assess the collision's impact and issue appropriate alerts, safeguarding driver safety and prolonging the vehicle's lifespan.

- Vehicle sentinel function: While parked, the system can act as a sentinel, precisely detecting if the vehicle sustains any damage due to scratches or collisions. This functionality enhances vehicle security and owner peace of mind.

Precisely capturing intricate data from compact touch sensors placed across various sections of a vehicle's body offers drivers, vehicle owners, and operational platforms a wealth of real-time information over a wide spectrum of automobile incidents. These incidents span from minor human interactions with the vehicle to more critical collisions.

Such comprehensive insight is made possible by employing a systematic approach, which encompasses an array of cost-effective sensors, each only a few millimeters in size. This ensemble of sensors is accompanied by a central controller and is orchestrated by intelligent algorithms rooted in elastic-wave technology.

Other Automotive-Related Elastic-Wave Touch-Sensing Features

Elastic-wave touch sensing introduces several other noteworthy features to the automotive market, enhancing safety and functionality:

- High sensitivity: The technology's sensitivity enables it to detect collisions even at extremely low speeds, such as 1 km/h. This heightened sensitivity ensures that even minor incidents are accurately captured, contributing to comprehensive incident detection.

- Prevention of inadvertent triggering: Elastic-wave sensing systems are designed to be responsive primarily to contact signals. Non-contact signals like bumps, acceleration, and deceleration are less likely to inadvertently trigger the system. The system responds distinctly only when there's an actual collision resulting in contact with the vehicle's surface.

- Material discrimination: The technology is able to discern the type of object causing an impact. For instance, TAIPS can analyze the characteristics of the elastic-wave signals and use complex algorithms to accurately identify the material or type of object involved in the collision.

- Precise collision location: Elastic-wave touch sensing can accurately determine the specific area of the vehicle body where a collision took place. This level of precision provides critical information for diagnostics, repairs, and understanding the nature of the incident.

With these features, elastic-wave touch sensing becomes a valuable asset in the automotive industry. Its sensitivity, specificity, and ability to distinguish impact characteristics bring a new level of insight and accuracy to incident detection and analysis.

More Possible Applications for Elastic Wave

The potential of elastic-wave touch-sensing technology extends far beyond its applications in the automotive industry. Its unique ability to function within solid media opens up a wide array of promising possibilities across various domains. Other applications where elastic-wave touch sensing can make a significant impact include:

- Gloves and wet-finger sensing: Elastic-wave touch sensing's adaptability makes it suitable for deployment in scenarios involving gloves, even when they're wet, offering enhanced touch capabilities for wearable devices.

- Irregular surfaces: The technology's versatility enables it to be employed on irregularly shaped surfaces, allowing for touch interactions in non-standard configurations.

- True wireless earbuds: Elastic-wave touch sensing can be harnessed to identify a range of touch gestures and actions, such as clicks, slides, short and long presses, and even their respective positions, forces, or speeds. This advance enhances the user experience in devices like true wireless earbuds.

- Mobile devices, tablets, robotics, wearables, and AR/VR: In these applications, elastic-wave touch sensing offers a comprehensive solution encompassing 3D touch, gesture recognition, positioning, and force sensing.

In summary, elastic-wave touch-sensing solutions have found homes in many consumer electronics and automotive applications. It has the potential to reshape user interaction in a wide range of fields and is expected to revolutionize the intelligent-hardware industry.