Members can download this article in PDF format.

What you’ll learn

- Introduction to wire harness design for aerospace systems.

- What are the challenges in wire harness design?

- Digitization and development software.

Today, aerospace and defense product manufacturers are under tremendous pressure to do more with less, and get it done faster due to ongoing changes, budgetary constraints, and increasingly stringent regulations. As they seek to improve product performance and functionality by replacing legacy mechanical systems with electrification and software, they face numerous challenges related to quality, delivery, and cost.

The pressure to reduce program costs and accelerate schedules while meeting requirements is one of the biggest challenges. Concurrently, aerospace programs are becoming highly integrated and thus increasingly complex stemming from challenges in designing, manufacturing, and certifying new products, and bringing them to market quickly.

Another trend making an impact is the increase in electrification, driven by automation and the desire for greener solutions. As companies seek to improve their product performance, reduce weight, and provide more functionality, integrated solutions that rely on more software are required. Mechanical systems such as hydraulics are being replaced with electrical systems to improve reliability and maintainability.

All of this is occurring against a backdrop of increasingly stringent regulatory oversight. Major efforts to delegate authority to original equipment manufacturers (OEMs) have progressed, but not at the pace desired by the industry. Recent high-profile aircraft safety concerns have prompted regulatory agencies to be directly involved in certification activities. One way to get ahead of regulatory requirements is to complete design validation earlier in the development process, but this can be onerous and time- consuming.

Forward-thinking companies are moving toward digitalizing product design. Solid and robust harness design forms the foundation of reliable, high-quality, and cost-effective product manufacturing to support on-time delivery. As a platform design moves from virtual to real product, the use of a configuration-controlled electrical digital twin brings critical advantages to the design of wire harnesses essential in modern aerospace and defense products.

Wire Harness Design Challenges

Designing wire harnesses for aerospace products is a highly complex endeavor that presents numerous challenges relating to quality, delivery, and costs:

- Quality: A reference quality standard needs to be established. The required product quality is an absolute requirement. Engineers often focus on achieving the best-possible quality, but that’s different from the quality standard. The required level of quality as defined by the standard is the goal. For example, there may be a certain value for connection resistance, dimensional accuracy, or other metrics that must be met, so having a clear understanding of the target quality standard is essential.

- Delivery: Product delivery is the top priority when it comes to satisfying customer expectations and driving revenue. Numerous daily challenges, from material shortages to unplanned errors and rework, can put product delivery at risk. Ultimately, engineering teams must have control of the delivery schedule. The better one can forecast and execute on the delivery commitment, the more successful the product. Revenue depends on product delivery, so it’s tempting to focus on accelerating delivery as much as possible. Thus, concentrating on reducing cycle time by boosting responsiveness is a more effective approach.

- Cost: Any form of operation generates revenue, but there are costs that reduce profits. The main components of costs are labor, materials and services. To cut down on expenses, the elements of the organization’s processes must be examined to determine what can be eliminated. While some cost drivers are out of one’s control, the focus should be on minimizing the controllable costs, such as labor, rework, and warranty costs, to increase margin.

The Shift Toward Digitalization

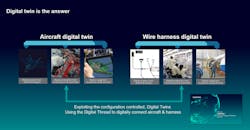

Forward-looking organizations are shifting from the traditional harness design approach to digitalization. A digital twin of the entire aircraft for multiple design disciplines can be connected so that information is able to be accessed directly or transferred digitally to create a common digital thread, supporting the flow of information up and down the design and manufacturing chain.

By creating a virtual copy of the design, the harness can be validated electronically against design rules (Fig. 1). This eliminates the need to manually transfer and transcribe information between the design disciplines.

A digital twin allows for the integration of disciplines, teams, and domains for seamless data sharing, reducing delays during handover. It enables early and frequent analysis to reduce risk by validating systems prior to and during implementation. Teams can optimize designs, production, and product utilization using simulations while ensuring requirements traceability.

When wire harness design is included in electrical system design, simulations and analysis can be performed without the use of complex mathematical models, product prototyping, or mental gymnastics. A digital twin helps teams be proactive and detect potential problems early, resulting in higher product quality, accelerated delivery, and reduced costs.

Digital Twin Creation

Creating a digital twin is much easier than expected. Simply combine the aircraft harness topology and wiring connections to create a comprehensive model that enables a digital process (Fig. 2). The result is a virtual harness model that contains not only the geometry, but all of the wiring data, creating a solid foundation for further processing according to the unique requirements of the customer or business model.

The value delivered by creating a digital twin can be illustrated with a pyramid diagram (Fig. 3). At the bottom is the model—the foundation for model-based electronics engineering (MBEE). The model, as the digital twin, can contain more information than normally captured in a traditional 2D drawing.

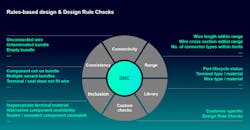

The second layer is validation, which consists of automated design checks, eliminating human-led iterations at this level. These design rule checks help to ensure connectivity, range, consistency, and other elements of a high-quality harness design (Fig. 4).

The system can verify the design based on standard or customized tools. For example, rules-based design and design rule checks can ensure connectivity by allowing users to check if all of the wires have terminations at both ends and are connected, plus identify any empty harnesses. They can also verify range, which defines the limits within which a parameter must be contained (e.g., minimum or maximum cable length, the cross-sectional range of cable, or electrical connection parameters such as temperature range or environmental resistance).

The system checks whether the length and diameters comply with the requirements. It also automatically verifies that the parts being used are in accordance with the specifications in the library, and up-to-date. Library rule check assures that the materials used are allowed and approved for production.

The digital twin also lets users check component consistency and compatibility. For instance, do the contacts match the connectors? Are the receiving lowering plugs used appropriate? Was the right substitute used when needed, and the right material compatibility obtained? Each company has its own rules specific to a particular project or type of harness.

Finally, at the top of the pyramid is generative design—the use of automation design rules and processes for the automatic generation of designs, which are correct-by-construction. By developing solutions that meet criteria specified upfront, generative design enables the team to offload many of the laborious tasks associated with design evolution, assessment, and evaluation.

It’s important to highlight that this builds from the bottom-up, with additional value as the team builds out each layer of the pyramid.

E/E Systems Dev Software for Wireless Harness Design

For aerospace and aircraft system development, Capital software from Siemens offers a comprehensive electrical/electronic (E/E) systems development solution for complex platforms. The design automation capabilities in Capital, coupled with its model-based wiring harness engineering flow, helps harness manufacturers cut costs, improve product quality, and boost efficiency.

Capital Harness Designer enables the digital exchange of design data, eliminating errors, rework, and delivery delays. Since the design process is digitally connected across disciplines, teams benefit from model-based writing design and the ability to sync design details from the wiring diagram to the mechanical engineering team. The 3D routing information can be digitally passed to the harness design as well, eliminating error-prone manual calculations, and data interpretation and transcription.

The model contains more information than traditional design formats, including not only lengths and branch positions, but pin-to-pin connectivity, cavity materials, sizing, and even bend radius requirements for the bundle. The result is digital synchronization of the design elements, eliminating mistakes and rework, both during the design process and, more importantly, during final manufacturing. Accuracy is improved, with direct impact on the reputation of engineering teams responsible for the designs.

After the team creates the model, generates the bill-of-process, and establishes time and material cost calculations, the production line is optimized with all of the necessary instructions to manufacture the harness. The team can now move from the harness product engineering model to a digitized production process optimized and ready for production.

Digitalization is Critical for Next-Gen Aerospace Development

The aerospace industry demands more than just increased electrification. Aircraft versions, a greater amount of regulatory product and process requirements, and global competition are forcing the use of holistic systems that provide data transparency and configurability assured by seamless data flow (digital continuity).

Solid and robust harness design forms the foundation for reliable, cost-effective and successful aircraft manufacturing that meets these requirements. As the platform evolves from a virtual to a physical product, a digital twin delivers numerous critical advantages essential for building modern aerospace and defense products. By using a digital twin throughout the wire harness design and manufacturing process, design teams can realize:

- Higher quality due to rejection of error-prone manual methods.

- Data correctness when not exposed to manual iterations.

- Urgent updates with faster connected processes.

- Enhanced management of growing complexity.