Members can download this article in PDF format.

What you’ll learn:

- Insight into ultra-miniature semiconductor components and the accompanying challenges in efficiency and cost-effectiveness.

- Why xESD technology is shown to offer superior resolution and static-dissipative properties when compared to traditional methods.

- Why xESD benefits Nexa3D’s XiP desktop printer.

In the high-stakes landscape of ultra-miniature semiconductor components, demand continues to surge across critical sectors such as medical, aerospace, and defense. Amidst this burgeoning demand, manufacturers grapple with challenges in efficiency and cost-effectiveness.

This article delves into the potential of xESD (electrostatic discharge) technology in semiconductor component fabrication, offering improved resolution and static-dissipative properties. Through comparative evaluation and analysis, we uncover how xESD addresses the pressing demands of the industry, enhancing production processes and reducing costs.

Case Study: Pinpointing the Right Materials for Component Manufacturing

A manufacturer specializing in ultra-miniature semiconductor components for medical, aerospace and defense, and industrial sectors faced challenges with extended lead times and high costs linked to custom machined semiconductor component carriers.

This prompted an exploration into additive-manufacturing (AM) technologies to expedite new product introductions and prevent the need to replace entire testing equipment in case of redesigns of single component carriers. Specific requirements for the AM equipment and material options included achieving exceptional feature resolution and incorporating static-dissipative material capability.

The manufacturer encountered a challenge in finding the right combination of electrostatic-discharge (ESD) materials and AM equipment. Previous options, relying on filament-based AM, failed to meet intricate feature requirements. The capabilities of fused filament fabrication (FFF) equipment (Fig. 1) fell short of achieving the necessary precision, resulting in unusable components. Consequently, the manufacturer sought an alternative AM process that accommodates both high-resolution and ESD requirements.

Comparative Analysis of Surface Finish and Precision Between xESD and Competitor Technologies

To address the demand for high-resolution static-dissipative components, the manufacturer turned to static-dissipative resins for vat photopolymerization systems, offering superior resolution compared to FFF. A comparative evaluation was conducted between Nexa3D’s xESD formulated by Mechnano for ultra-fast LSPc 3D-printing technology and a resin and SLA machine combination from a competitor.

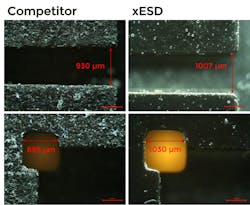

Results showed that semiconductor component carriers were fabricated using both the competitor and xESD, surpassing the resolution capabilities of FFF hardware (Fig. 2). Visual examination revealed clearly defined 1-mm pockets and channels, with noticeable differences in the surface finish. The competitor part displayed rougher surface quality compared to the smoother, nearly glassy surface finish of the part fabricated on Nexa3D’s XiP desktop printer with xESD.

Microscopy analysis and surface resistivity measurements were conducted to ensure that feature sizes and static-dissipative performance met application requirements.

Figure 3 shows microscopy images of the fabricated components. When comparing the competitor parts to the desired specifications, it was observed that there was a roughly 7% reduction in channel width and a 10% decrease in pocket size. The part fabricated using xESD exhibited a less than 1% increase in channel width and about a 3% increase in pocket size. The reduced pocket sizes in the competitor parts rendered them unusable.

In contrast, the slight increase in size observed in the part fabricated using xESD didn’t compromise the performance of the component. Fabricating high-resolution parts is essential due to the ongoing downsizing of semiconductor components, resulting in an increasing need for improved precision in their manufacturing processes.

Testing Static-Dissipative Properties: xESD vs. Competitor

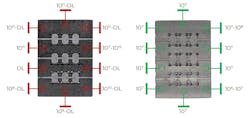

The static-dissipative properties were evaluated according to the ANSI ESD S11.13 – Standard Test Method for the Protection of Electrostatic Discharge Susceptible Items – Two-Point Resistance Measurement. Measurements were taken at 10 locations on the part’s surface. Three separate specimens were tested for each resin, and the values were reported in ranges (Fig. 4).

The competitor part had resistance ranging from 107 to 1011 Ω, with multiple instances where an “Open Loop” reading was observed. An “Open Loop” or OL reading indicates that the tested component lacks continuity and possesses infinite resistance. Infinite resistance implies the absence of an electric current flowing through the component.

In contrast, parts fabricated with xESD displayed highly precise surface-resistance measurements, ranging from 106 to 108 Ω. The resistivity at any specific location on the component either varied by one order of magnitude or remained constant at 107 Ω.

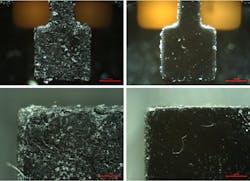

The observed variations in the static-dissipative performance can be attributed to the noticeable disparities in the surface quality of the components and the quality of the CNTs dispersion in a resin. As noted, the competitor components exhibited a visibly rougher surface finish in contrast to the smooth surfaces of xESD parts. Microscopy images further illustrate this discrepancy (Fig. 5).

The competitor part displayed an exceedingly rough surface finish with noticeable pitting occurring in multiple locations. When the electrodes of the resistance probe came into contact with the surface of this component, the presence of roughness restricted the effective connection between materials to only a portion of the available area. As a result, the current flowed solely through the true contact areas, while the roughness introduced contact resistance.

This contact resistance explained the significant differences observed in the surface resistance measurements obtained from the competitor part when compared to uniform measurements of xESD components.

Determining Dispersion Quality

Dispersion quality served as another factor contributing to the discrepancy in ESD readings (Fig. 6). The images clearly indicate that competitor resin contained a higher concentration of CNTs compared to xESD. The crucial distinction between the two was the inferior dispersion quality observed in the competitor resin, where a significant number of CNT bundles coexisted alongside regions lacking CNTs.

In contrast, microscopy of xESD demonstrates a well-distributed and uniform dispersion of CNTs without the formation of CNT bundles or areas devoid of CNTs. This was due to the integration of xESD’s proprietary discrete, dispersed, and functionalized CNTs (D’Func) into the resin.

Achieving high-quality dispersion is imperative to ensure a homogeneous distribution of conductive additives within the polymer matrix. This distribution enables the formation of conductive bridges, consisting of overlapping electronic structures, which facilitate electron transfer. The presence of regions without CNTs and highly concentrated areas adversely affects the uniform distribution of the conductive filler in the manufactured component, resulting in sections with inconsistent conductivity.

Reducing the Time and Expense of Semiconductor Component Production

Utilizing xESD and XiP offers numerous advantages, including a smooth surface finish, consistent surface resistance, and exceptional feature resolution. Incorporating xESD and XiP within the manufacturing facility enables the manufacturer to diminish the expenses linked with design iterations and facilitates the optimization of tooling.

Shifting from outsourced machining services to in-house fabrication utilizing xESD and XiP significantly shrinks part lead time, decreasing from 8 weeks to just 2 hours, accompanied by a cost reduction of 84%. Ultimately, this potent combination empowers the manufacturer to swiftly produce functional semiconductor component carriers while minimizing both time and expenses compared to conventional manufacturing approaches.