Download this article in PDF format.

Have you ever wondered how many motors you own and use at home? Probably not, and do you really care? But if you took an informal inventory, you’d likely be surprised. Your home is loaded with motors. A/C units, washers, dryers, refrigerators, pool pumps, and way too many small ones to count (shavers, hair dryers, ceiling fans, kitchen appliances, power tools, and even the driver motors in your DVD player or CD player if you still own one.

However, in most factories, process control plants, and office buildings, there are even more motors pervade for HVAC, machine tools, robots, pumps, automated machines of special design, forklifts, and hundreds perhaps thousands beyond those. Motors run the show in industry and many other fields like automotive, aerospace, and military.

What runs all those motors, though? Electronics, obviously, but what kind? An embedded microcontroller is usually at the heart of it along with some auxiliary circuits. Now, STMicroelectronics has some new MCUs that address this opportunity and deliver some much-needed benefits like greater efficiency, smaller size, and speed of development.

Sponsored Resources:

- STSPIN32F060x 600 V Three-Phase Controller with MCU

- STSPIN32F0 Motor-Control System

- STSPIN32F025x 250 V Three-Phase Controller with MCU

The Three-Phase Challenge

Many of the motors that require control are of the three-phase variety. These include the popular brushless DC motors (BLDCs). The motor-winding phases are driven by pulse-width modulation (PWM), which develops the signals that change speed, frequency, or other variables. The usual configuration is a microcontroller (MCU), a special motor driver IC, and the MOSFETs or IGBTs that deliver the current and voltage to each motor winding.

It’s usually desirable to package all of those ICs and related parts in the smallest housing possible to fit the motor location. That’s been a major problem over the years, but there are much better options now.

For example, STMicroelectronics recently announced a new line of MCUs that provide the benefits mentioned above. The top-of-the-line product is the STSPIN32F060x in a 64-pin system-in-package (SiP). Buried in this hybrid package is a 32-bit Arm Cortex MCU-M0 processor. Also integrated into the SiP is a triple half-bridge gate driver, which drives the external MOSFETs and IGBTs. These drivers can deliver an input signal that will work for most applications.

About the MCU

Inside the STSPIN32F061 is ST’s STM32F031x6 MCU. It’s a typical Arm 32-bit Cortex that runs at 48 MHz. It offers 4-kB SRAM and 32-kB flash memories. Other features include six general-purpose timers and advanced timer control for PWM generation; a CRC generator; up to 10 channels of 12-bit ADC; I2C, USART, and SPI interfaces; plus up to 21 general-purpose I/Os.

The Gate Drivers

Included in the STSPIN32F061 package are three-phase gate drivers. Driving the gates of high-voltage power MOSFETs or IGBTs is tricky—the gate-drive signals need to be fast, handle high current, and deliver the right voltage level. The internal driver section can handle up to 600 V and, importantly, the gate current capability of the device is 1 A/0.85 A (source/sink). Each gate-driver output comes from a half-bridge compatible with N-channel MOSFETs or IGBTs. You can drive the high side or the low side of the half-bridge.

Another Version

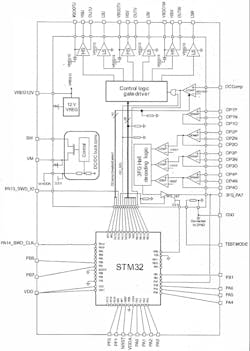

A similar IC worthy of consideration is ST’s STSPIN32F0 (see figure). It, too, integrates the Arm MCU and three-phase half-bridge outputs. Operating voltage is 8 to 45 V. The chip also contains op amps to accept sensor feedback from the BLDC motor windings. This permits field-oriented control (FOC) and other motion-control schemes.

The STSPIN32F0 series has some important differences compared to the STSPIN32F061. For one, the STSPIN32F0 series has integrated power management (not present in the HV series). Secondly, it has different gate source/sink current capability. While they both integrate MCUs and half-bridge drivers, the high- and low-voltage devices are manufactured in different semiconductor processes, leading to different feature sets.

Wrapping Up

If you’re designing or anticipate designing a complete three-phase BLDC motor-driver product, these STMicroelectronics devices will most likely get you there faster and easier than you think. In addition to the ICs, the company provides development boards and plenty of software to help you get your prototype running more quickly.

For example, the Motor Control SDK supports many demos for the entire family of STSPIN32 devices, and allows the user to generate C code for FOC in a matter of minutes. This powerful tool enables engineers to spin a motor very quickly and evaluate the performance of the devices and their own solution, reducing time to market. For further information, click here.

Sponsored Resources: