Members can download this article in PDF format.

What you’ll learn:

- Power faults in industrial automation create most equipment-related failures.

- Modern protection ICs can prevent power faults and maximize factory uptime.

- Examples will demonstrate improved reliability for next-generation production lines.

Uptime is a critical metric for productivity and profitability in applications such as industrial automation, building automation, motion control, and process control. The downtimes are typically caused by maintenance, human errors, and equipment failures. The cost of repairs and lost productivity associated with downtimes can be very high depending on the industry and the nature of the event.

Maintenance- and human-error-related downtimes can or cannot be prevented, but the majority of the equipment-related failures are preventable. This article focuses on downtimes caused by power faults and how they can be prevented using the modern protection ICs in the power systems of these equipment.

System Power Protection Overview

A power system is subjected to many electrical stressors and faults. Along the electrical path, voltage surges and transients due to lightning strikes or inductive load switching, inrush currents due to the initial charging of the storage capacitors, reverse voltages due to wiring errors or accidental shorts in the wiring harness, overcurrent, and overtemperature can induce degradation or irreversible damage.

It’s necessary to build a perimeter of protection around the load to handle those potentially catastrophic events. Let’s review some common terminology, types of power faults, what traditional solutions are available along with their challenges, and the modern protection ICs and their benefits.

Common Terminology

Besides the discrete solutions, a host of integrated solutions provide single-function protection. For example, a surge protector (or an overvoltage protector) offers protection against the voltage surges; a hot-swap controller (or an Inrush limiter) can protect against the inrush current; an ORing controller (or an ideal-diode controller) can protect against the reverse voltage as well as provide power sources distribution; an e-fuse (or a current limiter) can protect against short circuit or overloading; and a power limiter/load switch/USB switch/power selector provides management and control for the system with multiple input power sources and/or multiple loads.

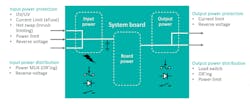

Figure 1 shows these products, which have a common purpose: deliver system power protection. They do, however, offer only a partial solution to protect the system against either voltage, current, or temperature faults. A holistic solution is needed to provide complete, comprehensive system power protection.

Where System Power Protection is Necessary

Figure 2 illustrates a generic system board power distribution. The board receives power from three separate input power sources, charges a large hold-up capacitor, creates board power for its own use, and passes on power to two subsequent peripheral devices. This system board requires several power-protection and power-distribution functions at both its inputs and outputs.

In terms of input power protection, it requires overvoltage/undervoltage, e-fuse, inrush limit, and reverse-voltage protection. If this board is powered from a source with limited power capability, then it would also need the power limit function.

Since the board receives power from three different sources, it requires power ORing or power multiplexer (mux)ing. Power ORing automatically selects the power source with the highest voltage to power the board, while power muxing gives the system the choice to select whichever power source to use, regardless of its voltage, as long as it’s within the operating range. The board also needs reverse-voltage protection so that a higher voltage power source doesn’t back drive a lower voltage one.

Now, for the output power protection, the board needs current-limit protection against output overload or a short on the connector, and reverse-voltage protection against an accidental short to a higher voltage rail. To manage output power distribution, the board requires load switch, ORing, and power limit.

Three Main Types of System Power Faults

There are three main types of system power faults (Fig. 3): voltage, current, and temperature faults. Let’s closely examine each one of them in more detail.

Voltage Faults

Input voltages can go higher and/or lower than the normal dc voltage range due to a number of incidents, such as lightning strikes, blown fuses, short circuits, hot-swap events, and cable inductive ringing.

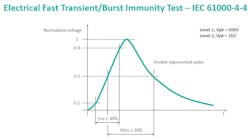

A lightning strike may cause a high-energy surge voltage that’s typically handled by a front-end transient voltage suppressor (TVS) device and input filter. Figure 4 summarizes the IEC 61000-4-4 electrical fast transient specification. After the TVS and input filter, the residue surge voltage at system board level can still be quite large, sometimes 2X to 3X the nominal dc input voltage.

Figure 5 demonstrates a short-circuit event where a brief short circuit at the end of a 10-foot cable causes its voltage to ring and peak to 50.4 V, doubling its 24-V dc normal voltage. The voltage also rings down to about 11 V. A robust system would continue to operate throughout this ringing without interruption or, at least, survive it without damage. Similar voltage ringing can happen during a hot-swapping event where a card with a discharged capacitor is plugged into a live backplane, during an inductive load switching event, or when a blown fuse occurs elsewhere in the system.

System miswiring is rare but, nonetheless, can occur. For example, in a rack-mount system, a person might plug in a card in reverse or connect the power cable with the wrong polarity. When the input voltage drops suddenly (the input is shorted or rings low), the output capacitor is now at a higher potential, which causes a reverse-voltage condition. A reverse-voltage condition can also occur when the output is suddenly shorted to a higher voltage rail (in a bundled cable, for example). Though input reverse-voltage faults are rare, when they do happen, they may lead to costly system damage.

Current Faults

Output overloading and short-circuiting are two obvious current faults. Overcurrent loading is triggered when the system runs overcapacity. And a short circuit can be caused by a faulty component on a board. A bad short circuit could happen if someone accidentally drops a wrench onto the power connector or drills into a cable bundle. Unprotected boards may suffer permanent damage or, worse, catch fire.

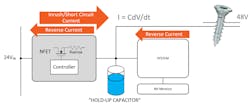

When a board with a discharged capacitor is plugged into a live backplane, a surge of current rushes in to charge up the capacitor. Uncontrolled, such inrush current follows this equation:

I = CdV/dt

where I = inrush current; C = capacitance; and dV/dt = rate of change of the capacitor voltage over time.

If a discharged capacitor (at 0 V) is plugged into a live backplane at 24 V, dV/dt in this case is instantaneous (infinite), translating to I = infinite. Without inrush control, this infinitely high current spike can damage connectors, blow up fuses, and cause voltage ringing on the backplane voltage.

When a reverse-voltage event occurs, current flow in the reverse direction may severely damage the system. Figure 6 illustrates inrush/short-circuit and reverse currents.

Temperature Fault

If designed properly, a system should be able to operate without ever experiencing a temperature fault. But a primary fault condition—e.g., an extended overload condition, failed or failing system fan, accidental blocking of the system air inlet/outlet, or failure of the room A/C—can trigger a temperature fault.

To prevent damage and potential fire-related problems, overtemperature protection shuts down the system when its temperature, or one of its other components, reaches a dangerous level. Compared to an overtemperature shutdown, thermal protection has more intelligence. When the temperature rises higher than the normal during the operation due to a primary fault, thermal protection provides the system with a warning and options.

For example, the system can choose to shed noncritical loads, running at a lower switching speed to dissipate less power. As a result, the system might be able to avoid an overtemperature shutdown with reduced system performance until the primary fault is resolved.

System Implications without Protection and Design Challenges

It’s because all electrical systems experience voltage, current, and thermal faults, neglecting protection can hamper the successful completion of system designs during the design verification test stage. In fact, an even worse scenario involves line-down situations on the factory floor. Protection circuitries to holistically safeguard against equipment-damaging faults are valuable for maximizing the system uptime.

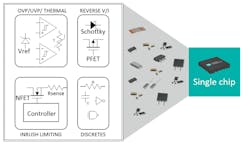

System engineers who want to fully protect their products face some design challenges. A discrete or partly IC implementation calls for many external components. Figure 7 illustrates a complete system power-protection solution using 40 discrete components. The tolerance stack-up of the components is tedious to analyze, and it’s difficult to verify and guarantee the performance over time. It’s also difficult to achieve system accuracy and fast response time to faults.

With multiple components, the resulting solution is large. Moreover, cost of ownership is high due to low system mean time between failures (MTBF).

System Protection Made Easy

The traditional ways of implementing protection with discrete circuits or partly ICs might have worked fine in the past, but it doesn’t work for modern systems. Modern systems have smaller board spaces, shorter development schedules, and tight development budgets. Given this transformation, what is the most suitable protection solution for modern systems?

The solution is a highly integrated protection IC (Fig. 8) that integrates field-effect transistors (FETs), current sense/limit, power limit, thermal protection, and undervoltage/overvoltage protection. A fully integrated protection IC that meets the Underwriters Laboratories Inc./International Electrotechnical Commission (UL/IEC) safety requirements is even better. Higher integration in combination with safety certification results in reliable protection for modern systems.

Protection IC Examples and Key Working Concepts

The MAX17613 and MAX17526 developed by Maxim Integrated represent examples of protection ICs that would fit the requirements of modern systems.

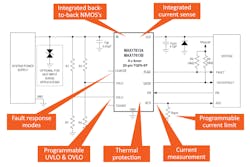

The MAX17613 (Fig. 9) is a 60-V/3-A protection IC that has key components and features such as forward and reverse FETs, programmable current sense, thermal protection, programmable undervoltage lockout (UVLO) and overvoltage lockout (OVLO) integrated into a single IC. There’s also a pin “CLMODE” to select the IC’s mode of response to current faults between continuous, latchoff, and autoretry modes.

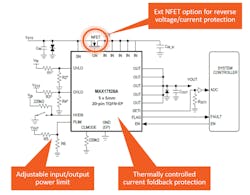

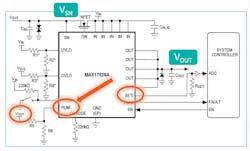

The 60-V/6-A MAX17526 (Fig. 10) is a fully integrated protection IC, too. It also has advanced protection features such as power limit and thermally controlled current foldback. Let’s review a couple of key features in detail using the MAX17526 as an example.

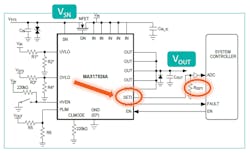

As shown in Figure 11, the MAX17526 measures the current drawn by the system and reports it to the system controller using the pin “SETI.” The resistor “RSETI” can be adjusted to program the current-limit level per system requirements.

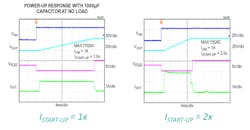

Figure 12 demonstrates the MAX17526’s current-limit function and how it controls the inrush current during system power-up. A large 1000-µF capacitor is charged in a controlled fashion at 1.0X of the current-limit value (on the left) and at 2.0X of the current-limit value (on the right) without crashing the voltage source.

Figure 13 shows the MAX17526’s unique power-limit feature that can be used to limit the input or output power depending on whether the node “VEXT” is connected to the input voltage (VSN) or output voltage (VOUT). The IC adjusts the current limit dynamically to achieve the input or output power limit.

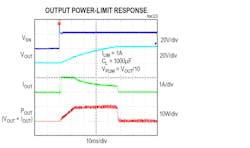

Figure 14 illustrates how the power-limit feature works to limit the output power at 10 W when the IC is configured to limit such power.

UL/IEC Safety Certification

As discussed earlier, modern systems can take advantage of any safety-compliance aspects of the protection ICs as well. A protection IC that’s recognized by UL2367, IEC60950, or IEC62368 can simplify the system-level safety requirements, which can reduce certification-related costs and shorten the certification schedules to help with faster time-to-market. For example, the MAX17608 and MAX17613 from Maxim Integrated are UL- and IEC-recognized protection ICs.

Conclusion

Power systems are critical blocks for any system or equipment. Power faults are inherent and do happen, but by implementing proper circuit protection, system failures and equipment downtimes can be prevented. That’s critical for productivity and profitability, especially in today’s highly competitive global business environment.

Compared to the traditional discrete or single-function IC solutions, today’s advanced protection ICs offer holistic system protection in small packages with high performance and high reliability, and which are easy to design and qualify. Also, some of the advanced features offered by these protection ICs enable system monitoring and diagnostics features that can be instrumental in today’s complex end equipment. Investing in fully integrated protection ICs is the cheapest insurance against costly downtimes.