Members can download this article in PDF format.

What you'll learn:

- Common traits of digital multimeters (DMMs).

- Classifying DMMs by their amount of digits.

- What role do digitizers play in making voltage measurements?

Measuring voltage may be the most basic measurement you can make on a cell or battery. Cell or battery voltage is used to determine the state of charge, the resistance, and other key behaviors of the cell. Current is determined by measuring the voltage across a current-sense resistor or current shunt.

Depending on the sensor type, temperature is determined by measuring the voltage across a temperature sensor, and resistance is determined by measuring the voltage response of the cell or battery to a current stimulus. Finally, auxiliary voltage measurement points are measured to determine proper functional operation of the battery system.

With all of these voltage measurements, it’s important to understand how to make the voltage measurement properly to gain the desired measurement insight. In some cases, very accurate voltage measurements are needed, and measurement time is a secondary consideration. In other cases, capturing dynamic voltage behavior is needed, such as looking at voltage response to a current pulse. When faced with these scenarios, a fast digitized voltage waveform is required to observe the response voltage versus time, and voltage measurement accuracy will be the secondary consideration.

DMMs for High-Accuracy Measurement

The basic dc voltage measurement device is a digital voltmeter (DVM). Most DVMs today do much more than just measure dc voltage by including measurement of ac voltage, ac and dc current, resistance, and capacitance (Fig. 1). In these cases, the DVM is called a digital multimeter (DMM). Regardless of whether you have a DMM or DVM, they both measure dc voltage, so I’ll refer to this instrument as a DMM, as this is the more commonly available configuration.

DMMs come in many different configurations. Handheld DMMs are very convenient when you need to quickly measure a voltage at a test point, but they’re not suitable for a cell or battery test system.

Benchtop or system DMMs, like the DMM shown in Figure 1, are commonly integrated into test systems. These instruments are rack-mountable and can be controlled remotely over digital programming interfaces like Ethernet or USB. Such DMMs have a front-panel display, so that they can offer high confidence during testing because you can see the measurements that are made.

1. A typical system DMM suitable for cell voltage measurements is the Keysight model 34470A.

DMMs are also available in modular instrument form, such as PXI, which offer reduced space in the system, but sacrifice the front panel operation. Reputable DMMs are calibrated and traceable to national standards, so you can trust the measurement.

How Many Digits?

DMMs are classified by the number of digits, with the lowest performance being 3.5- and 4.5-digit versions. The typical DMM used in cell and battery test systems have 6.5 and 7.5 digits. The highest-performing DMMs are 8.5 digits, but these are seldom used in cell or battery test systems.

While performance of the DMM typically tracks the number of digits, it’s important to understand that the number of digits refers to the resolution of the DMM, not necessarily the accuracy. Generally, 7.5-digit DMMs are more accurate than 6.5-digit DMMs, 6.5-digit DMMs are more accurate than 4.5-digit DMMs, and so on. But understanding the datasheet of the DMM is important to understand the actual accuracy you will get when using it.

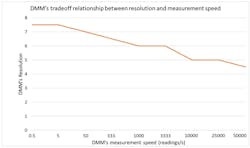

Independent of the number of digits, when using a DMM, the length of the measurement time determines the performance of the measurement (Fig. 2). The DMM voltage integration time is the programmable parameter that you can adjust to trade off measurement speed for measurement performance. Longer integration times enable the DMM to reject noise and give a better measurement. Shorter times will be less accurate due to increased noise, but it’s possible to accelerate readings.

2. The chart illustrates DMM resolution in number of digits versus DMM measurement speed in readings per second.

Accuracy and Throughput Tradeoffs

Therefore, understanding how accurate you need to make the measurement will tell you the achievable measurement throughput. For 50-Hz AC power system, a measurement interval of 100 ms or two power line cycles (PLCs) will often reject enough noise whereby you can get a reasonably accurate measurement without sacrificing too much measurement speed. The resulting measurement is suitable for determining cell or battery open circuit voltage with relatively high confidence.

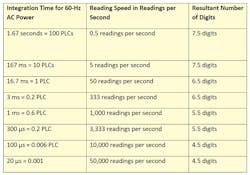

Likewise, for 60-Hz AC power systems, a measurement of 120 ms can be sufficient. Note that as you adjust the measurement interval or NPLC (number of power line cycles), you will be effectively changing the DMM’s number of digits.

A 7.5-digit DMM running at its highest speed (shortest integration time) will perform similar to that of a 4.5-digit DMM. It’s only at long integration times that you achieve the highest resolution (number of digits) and highest accuracy (through increased noise rejection) (Table 1).

Table 1: Relationship between integration time, reading rate, and resultant number of digits for a 7.5-digit DMM (Keysight model 34470A).

A final consideration of DMM accuracy depends on the measurement range setting of the DMM. While DMMs can easily measure millivolts and microvolts with high accuracy, measuring these minute voltages will require the DMM to be in a low full-scale range, such at 10 mV full scale.

If you’re trying to measure a cell voltage of 3.65 V, you can’t measure on the 10-mV range. You’ll need to be on a range that’s larger than the cell voltage. This could be a 5- or 10-V range. On the DMM’s 10-V range, the accuracy will yield 100s of microvolts or even a few millivolts of error. Be mindful of this when trying to measure small voltage changes on top of the cell or battery voltage, which is commonly done when measuring resistance or aging.

For DMMs, clearly there’s a tradeoff between speed and accuracy. For the highest-accuracy measurements, individual long integration time measurements are needed. For example, if you’re measuring the drop-off of open circuit voltage during aging, you will want to use the longest measurement integration time, because you’re trying to accurately measure millivolt or microvolt changes in open circuit voltage.

Digitizers for High-Speed Measurements

Measuring a voltage waveform to observe voltage changes versus time will require a digitizer. In fact, better DMMs can be used as digitizers as well. In this mode, the DMM will rapidly capture individual measurements and store them in an internal buffer, allowing your program to pull that data out of the instrument in the form of a digitized waveform. As you can imagine, the faster you make these measurements, the lower the accuracy and resolution of the measurement.

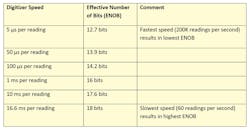

Pure digitizers are optimized for fast measurements, while DMMs are optimized for accurate long-measurement interval measurements. Digitizers are specified in number of bits, with 16 bits being common; however, 20-bit and 24-bit digitizers are available.

Just like a DMM, a digitizer provides programmability to trade off speed for accuracy. As you increase the digitizer’s speed, the number of bits will be reduced, along with the digitizer’s accuracy. When you read the performance specifications of a digitizer, you will see the term “effective number of bits” (ENOB). The ENOB describes how the digitizer’s performance will be adjusted with increasing speed (Table 2).

Table 2: Digitizer speed is compared with resultant effective number of bits (ENOB). The digitizer has 18-bit maximum resolution with a maximum speed of 5 µs per reading.

Even a high-resolution digitizer will have significantly lower accuracy and resolution at full speed. Therefore, you can capture rapidly changing voltage waveforms (thanks to the speed of the digitizer), but you will not be able to resolve small steps in the voltage due to the reduced accuracy and resolution of each measurement point.

For example, when making a DCIR measurement, you may want to capture the voltage and current waveforms using a digitizer to ensure you can see the fast-rising edge of the voltage waveform, which determines the ohmic resistance of the cell or battery. But if the digitizer’s accuracy and resolution are insufficient, you will have too much measurement uncertainty in the voltage measurement. Thus, you will not be able to accurately assess the change in voltage caused by the pulsed current. This could result in a DCIR with a large error, like 1 mΩ ± 0.5 mΩ.

Summary

By understanding the performance specifications of the voltage measurement instrument and the tradeoff of speed, accuracy, and resolution, you’ll better know when to use a long-integrated measurement from a DMM versus a high-dynamic measurement from a digitizer. This will lead to achieving the best possible measurements from your test system.