This article is part of the This Week in PowerBites Library Series.

Are Grid-Forming Inverters the Missing Ingredient for Sustainable Power Grids?

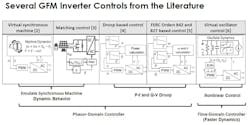

This includes so-called "grid-forming inverters" (GFIs), a special type of inverter that can provide existing electrical generation and distribution networks with distributed regulation capabilities. They allow networks to work more efficiently with the rapidly varying power levels that can sometimes occur in wind and solar farms.

Unlike the conventional "grid-following" inverters used by utilities to synchronize their generating assets' outputs with the rest of the grid, GFIs can interact with it by sensing changes in its amplitude, phase, and frequency. Subsequently, they respond in real-time to adjust its output frequency, which injects more or less power as needed to stabilize the entire network.

As a result, GFIs can help power grids accommodate the constantly varying outputs of wind and solar farms, and at a significantly lower cost than the battery and kinetic energy-storage systems currently used today. In addition, GFIs can be used to create highly resilient "micro-grids" within large regional power grids that could be independently restarted when a natural disaster or some other calamity brings down the larger network.

A recent article in Science News documents how the U.S., U.K, Australia, and several other nations are beginning to investigate the large-scale adoption of grid-forming inverters. Titled "How one device could help transform our power grid,” the story introduces some of the concepts behind grid-forming inverters and highlights several local and national initiatives currently underway to make the technology easier and more economical to implement. One such initiative is the Australian Renewable Energy Agency's 176 million Australian dollar (about $118 million) investment in eight projects based on grid-forming technologies that will generate 2 GW of power.

In the U.S., the Department of Energy is funding a $25 million effort to work on how to get more grid-forming inverters into the U.S. power system. This includes addressing basic issues such as drawing up suggested guidelines on how companies should build grid-forming inverters.

The efforts are mostly being conducted by a consortium, known as UNIFI, for “universal interoperability for grid-forming inverters,” led by the National Renewable Energy Laboratory in Golden, Colo., along with the University of Texas at Austin and the Electric Power Research Institute in Palo Alto, Calif. Among its accomplishments, UNIFI released draft standards meant to serve as a first step toward a national grid code that includes technical specifications for equipment, with a second, updated version anticipated by the end of the year.

Rugged Isolator Devices Extend Lifetime of High-Voltage Applications to 40+ Years

A new series of integrated "opto-emulator" signal-isolation semiconductor devices from Texas Instruments offer better performance than conventional optoisolators, according to the company, and aren’t subject to the age-related degradation they experience. By integrating the emitter and receiver in a single chip, the new devices improve signal integrity, consume less power, and extend the lifetime of high-voltage industrial and automotive applications.

SiO2-based Isolation Increases Reliability

Conventional optocouplers, which co-package a discrete LED and optical receiver, typically require upfront overdesign to compensate for the inevitable aging effects of LEDs. TI’s opto-emulators eliminate the need for overdesign by using SiO2 for the isolation barrier, removing the effects of LED-aging altogether.

With a high dielectric strength of 500 VRMS/µm, TI’s SiO2 isolation barrier enables the new portfolio of devices to protect end-product designs for more than 40 years. Opto-emulators also provide isolation protection as high as 3,750 VRMS, while reducing power consumption by as much as 80%.

This new class of devices is able to withstand operating temperature ranges from –55 to 125°C, while providing common-mode transient immunity up to 10X higher than optocouplers. To learn more about the benefits of TI’s new opto-emulators, read the technical article, "Opto-Emulators Explained: Why You Should Upgrade Your Optocoupler Technology."

Package, Availability and Pricing

- Package options run as small as 4.8 × 3.5 mm.

- Evaluation modules start at US$19.00.

- Automotive versions of opto-emulator products are expected to be available in 2024.

Pre-production quantities of opto-emulator products are available now at www.TI.com/opto-emulators.

Electronically Marked USB-C Cable Assembly Controller Offers Up to 54-V Protection

Infineon Technologies added the EZ-PD CMG2, a USB-C Electronically Marked Cable Assembly (EMCA) controller with enhanced features, to its EZ-PD portfolio of USB-C Power Delivery (PD) controllers. The controller is designed to deliver robust USB-C PD solutions for applications such as Extended Power Range (EPR) USB-C, USB4, and Thunderbolt passive cables.

The EZ-PD CMG2 (Cable Marker Generation 2) is a dedicated EMCA controller designed for passive non-Thunderbolt and Thunderbolt Type-C cables and supports USB-PD 3.1 and Type-C 2.1 standards. EZ-PD CMG2-based USB-C EMCA cables can handle USB4 and TBT4 data rates and up to 240 W (48 V/5 A) of power. EZ-PD CMG2 provides integrated VBUS-to-CC as well as VBUS-to-VCONN short-circuit protection up to 54 V. In addition, it supports RA weakening to reduce power consumption and integrates an oscillator and IEC ESD protection.

The new controller comes with a configurable 47-byte storage space for vendor- and cable-specific configuration data and operates within a 2.7- to 5.5-V VCONN supply range. The integrated high-voltage protection of up to 54 V on CC, VCONN1, and VCONN2 pins safeguards against accidental shorts to the high-voltage VBUS pin on the Type-C connector, providing enhanced user safety. Furthermore, its industrial temperature range of −40 to +85°C and system-level ESD protection on CC, VCONN1, and VCONN2 pins ensure reliability and durability under challenging conditions.

The EZ-PD CMG2 controller with EPR is available in a compact, 9-ball wafer-level chip-scale package (WLCSP) with a footprint of 3.3 mm². It can be ordered now. More information is available here.

USB 3.1 Type-C High-Rise SMT Connector Ensures Reliable Assembly and Operation

Würth Elektronik's family of USB-C connectors now includes a 24-pin fully-configured horizontal high-rise receptacle for SMT assembly. The high-quality USB 3.1 Type-C connector enables complete visual control of soldering thanks to its two rows each with 12 contacts. It’s not only compatible with USB 3.2 Gen 1x2 signaling and USB Power Delivery standards, but the connector can also be used for alternative and accessory modes. This includes transmitting analog signals via the (D+/D−) pins.

The WR-COM USB 3.1 Type-C High-Rise SMT is designed for at least 10,000 mating cycles and operating temperatures from −40 to +120°C. The pin contacts as well as the outer retaining pins of the shielding are gold-plated in the contact zone to ensure the best possible connection to the PCB. The stable receptacle is suitable for all consumer and IT applications that are designed to exploit the options provided by the USB 3.2 Gen 1x2 standard in terms of data and power transfer.

This latest member of the USB product family is now available from stock without a minimum order quantity, and developers can order free samples.

A Large USB-C Ecosystem

The high-rise receptacle joins Würth’s large ecosystem of USB-C products that includes connectors, EMC filters, components for ESD overvoltage protection, and AC-DC to DC-DC power conversion for USB 3.1. Components available for the development of USB interfaces include, for example, pulse-stable WE-MPSB SMD ferrites for hot-plugin, high-efficiency pressed power inductors (WE-MAPI) for Vbus filters, current-compensated data line filters (WE-CNSW HF), and the WE-TVS diode for ESD line protection. In addition, the company provides numerous application notes and reference designs for the WR-COM and its related products.

A Compact, Robust 750-V SCR for GFCI/AFCI Apps

The X0115ML is STMicroelectronics’ first compact silicon-controlled rectifier (SCR) made for use in ground-fault circuit interrupters (GFCIs) and arc-fault circuit interrupters (AFCIs) that can withstand a surge peak off-state voltage of 750 V.

Thanks to highly sensitive triggering levels, X0115ML SCR thyristor is suitable for all applications where available gate current is limited. It offers a high blocking voltage of 600 V and a surge peak voltage of 750 V.

The small SOT23-3L package (2.75 × 3.10 mm) makes it the smallest thyristor on the market today, according to the company. In addition, designing with the X0115ML is simplified due to its 1.1-mm creepage distance that satisfies the UL 840 requirements for 120-V AC insulation without coating while meeting level 2 pollution regulations without extra certification.

STMicroelectronics also provides some informative background on GFCIs/AFCIs, their role in consumer and industrial safety, and some of the issues involved with their design in an informative blog post. A datasheet, as well as additional documentation, tools and software, and CAD resources are available here.

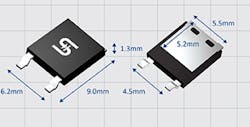

Schottky Rectifiers in ThinDPAK Packages Enable Higher-Power-Density Designs

A new ThinDPAK family of ultra-fast-recovery Schottky rectifiers was unveiled by Taiwan Semiconductor. ThinDPAK devices have the same footprint as standard DPAKs but come in a thinner (1.33 mm) package and offer greater power density and thermal performance.

Fully AEC-Q-qualified with a maximum operating temperature (Tj, max) of 175°C and typical reverse-recovery time of 25 ns, ThinDPAKs assure reliability in automotive power electronics, high-frequency inverters, steering diodes in HV applications, DC-DC converters, freewheeling diodes, reverse battery protection, lighting, and many other applications.

The planar Schottky topology of advanced ThinDPAK devices provides excellent rectification efficiency that dissipates less heat than alternatives. For the heat that’s dissipated, the new ThinDPAK devices’ thermal resistance (Rj∅A) is 21.9% lower. As a result, the devices offer reduced weight and headroom compared to standard DPAKs.

The ThinDPAK series comprises 34 devices with reverse-voltage (VVRRM) ratings from 45 to 200 Vdc with current ratings up to 150 A. Devices are available in single and dual (common cathode) configurations.

Click here for more information and links to complete product specifications.

Free Online PSU Design Tool Lets Designers Go from Spec to PCB Layout in Minutes

Power Integrations (PI) and SnapMagic announced that PI Expert, Power Integrations’ online design tool, now features schematic and netlist export made possible by SnapMagic’s new schematic export technology. Based on specifications input by the user, PI Expert automatically generates a complete power-supply schematic utilizing PI’s power-conversion ICs, including a custom magnetics design that can be directly exported to several popular CAD tools.

Previous versions of the automated tool flow covered everything up to full circuit optimization, but the files they generated had to be manually transcribed into a third-party CAD package to perform simulation and physical layout. The new export capability ensures a fast and seamless transfer of the design, including symbols, footprints, 3D models, and electrical netlist into one of four popular PCB CAD tools.

PI Expert Online is a web-based program that automatically generates a power-conversion solution from power-supply specs, providing everything necessary to build and test a working prototype. It includes a “ready-to-build” Transformer Construction Report, winding instructions, electrical and mechanical diagrams, bills of materials, and board-layout recommendations. No download or installation is required. PI Expert Schematic Export is compatible with user-defined custom components, and exported schematic files contain a readme text file providing step-by-step instructions for opening in the desired CAD tool.

To get started, engineers simply select File > Export Schematic and then select their PCB format of choice. SnapMagic’s schematic translator subsequently provides the completed schematic, including schematic symbols and PCB footprints for a seamless flow. In addition to the schematic export, CAD models for select PI components can be downloaded on the main SnapMagic Search website, previously known as SnapEDA.

At present, Cadence OrCAD, Altium, Autodesk Eagle/Fusion360, and KiCad are supported, with at least one more platform to be announced soon. The current version supports a curated subset of PI's power-conversion products elect parts (most of its InnoSwitch 3 series), but will eventually support all AC-DC conversion devices.

A more detailed introduction to the latest version of SnapMagic can be seen in this video; there’s also a library of video tutorials.

CAD Tool for Designing Custom Integrated BLDC Motor/Controller Systems That Deliver IE5 Efficiency

The Unum Potentia is a fully integrated, 5-kW electric motor controller crafted by ECM PCB Stator Tech. It’s fully customizable and facilitates the design and manufacture of highly efficient, low-cost drive systems. As a unit, the controller delivers a measured efficiency of 98 percent. The programmable controller was developed so that it could be easily optimized to deliver IE5 ultra-efficiency performance in electric motor systems based on PrintStator's unique PCB-based printed stator technology.

The PrintStator software platform enables designers to design, manufacture, and integrate highly efficient, three-phase, brushless DC permanent-magnet synchronous motors that can be tailored to meet their application's form factor and performance requirements. Instead of the bulky wound stators employed by conventional PMSMs, PrintStator designs employ compact PCB-based axial-flux stators that require up to 80% less copper to produce. They generate extremely low acoustic emissions while delivering efficiencies in excess of 90%.

Pairing the Unum Potentia with ECM’s PrintStator CAD platform enables full motor system optimization. The controller design can be configured by the PrintStator software through selection of the schematic's components to run motors from 3 to 8 kW. This allows the controller board’s footprint to remain the same.

In the process, it also generates motor-tuning parameters and translates them into a code file that can be uploaded to new controller. Should a full custom solution be desired, ECM's PrintStator software can also be used to optimize the design, enabling it to be fully integrated, both structurally and thermally, into the resulting motor housing.

Additional specifications of the Unum Potentia motor controller include:

- Operates on a 220- and 480-V three-phase AC supply.

- Offers sensorless control capable of running motors down to ~50 rpm.

- FETs are capable of switching upwards of 100 kHz.

Read more articles in the This Week in PowerBites Library Series.