This article is part of the Power Management Series: This Week in PowerBites

(Very) Smart Motor Controllers Powered by Arm Cortex-M4 MCUs

Toshiba Electronics announced 12 new microcontrollers in its M4K device group are now in production, all of which are specifically designed for motor-control applications. Toshiba also started mass production of an additional 10 motor-control MCUs for its M4M group.

All of these products are based on the Arm Cortex-M4 core equipped with a floating-point unit (FPU) and memory-protection unit (MPU), and capable of running at speeds up to 160 MHz. They integrate an advance-programmable motor driver (A-PMD), a 32-bit advanced encoder (A-ENC), an advanced vector engine plus (A-VE+), and up to three channels of high-speed, 12-bit analog-to-digital converters (ADCs). This makes these devices well-suited for field-oriented control (FOC) of ac and BLDC motors. They also can be used for most types of inverter controllers, including variable-frequency drives and servo drives.

The MCUs have onboard flash memory for code (128 kB/256 kB) and 32 kB for data, as well as a further 24 kB of general RAM along with a DMA controller (DMAC). Also included are six 32-bit timers that can be operated as 12 16-bit timers if desired. The analog section incorporates the previously described ADC plus an input multiplexer that supports up to 22 channels, as well as three op-amp channels.

All of the controllers in the M4K group feature multi-channel UART, SPI, and I2C interfaces for general communication. And the M4M group offers a CAN communication interface. Both groups have self-diagnosis functions for ROM, RAM, ADC, and clock, which allow designers to achieve functional-safety certification to IEC60730 Class B.

The products are packaged in a range of fine-pitch surface-mount LQFP packages with up to 100 pins, offering footprints as small as 10 × 10 mm. Comprehensive documentation, sample software with examples of actual usage, evaluation boards, and driver software with control interfaces for each peripheral are provided with every device shipped.

For additional information, email Toshiba at [email protected] or click here to visit the product family's home page.

eVTOL Student Design Competition Invites Proposals for Sponsorship

Requests for proposal (RFPs) to participate in the Vertical Flight Society's 2021/2022 Student Design Competition (SDC) are now available. This year's event, sponsored by Bell, welcomes student teams from around the world to propose innovative design projects that fulfill this year's design objective: “eVTOL Air Taxi for Passengers with Reduced Mobility (PRM).” Teams who submit RFPs that are accepted will receive funds to complete their designs from the competition's sponsors through the Society.

The theme of accessibility arose from the recognition that electric propulsion technology is shaping a future for advanced air mobility (AAM). Thus, to realize its full potential, designers must begin to accommodate as broad a spectrum of travelers as possible, including persons with disabilities of all types. As a result, this year’s SDC will challenge student teams to design an all-electric eVTOL aircraft concept that addresses PRMs and the unique requirements for such passengers.

All winning teams are awarded a cash stipend, while each of the first-place winning teams are invited to the Vertical Flight Society's Annual Forum and Technology Display to present the details of their designs. Final submissions will be judged in three categories: Undergraduate, Graduate, and Best First Time Entrant.

This event is one of several SDCs organized by the VFS that challenges students to design a vertical lift aircraft that meets specified requirements, providing a practical exercise for engineering students. This includes last year’s SDC “2025 Unmanned Vertical Lift for Medical Equipment Distribution” sponsored by Boeing Co. The winners will be announced within the next couple of weeks

Letters of Intent (LOI) for the 2021/2021 competition are due February 1, 2022. Potential entrants can download the RFP form and instructions for detailed information and deadlines on the event page at VFS Student Design Competition. It’s also recommend that you read the white paper Student Design Competition on Judging. Student Teams also can attend the Creating an Accessible Future Flight Workshop taking place virtually on Sept. 8.

SiC Power Solutions Offer Alternative to Si IGBTs for Industrial Trucks, Chargers and Other High-Power Apps

The introduction of Microchip Technology's 1700-V silicon-carbide (SiC) MOSFET die, discrete, and power modules appears to be one of the first significant challenges to silicon IGBTs' near-lock on applications that involve extremely high voltages and currents.

Until this year, the IGBT's mature technology, high current capacities, and robust characteristics have made them indispensable in applications such as commercial vehicle propulsion, super-fast EV chargers, and utility-scale renewable power systems. But the new 1700-V devices have much lower switching losses than IGBTs, thanks to their extremely low on-resistance and junction capacitance, which enable them to switch at much higher frequencies.

In addition to dramatically improved efficiency, the SiC MOSFETs' higher switching frequency shrinks the size and cost of the converter circuit's transformer. This, in turn, makes it possible to create smaller, lighter, lower-cost power-conversion units for charging stations, electric trucks, buses, and other battery-powered commercial vehicles.

Other advantages include:

- Improved gate-oxide stability that stabilizes the MOSFETs' threshold voltage. Extended tests indicate the devices experience no significant drift, even after 100,000 pulses in repetitive unclamped inductive-switching (R-UIS) cycles.

- The R-UIS tests also demonstrated excellent avalanche ruggedness and parametric stability, and with gate-oxide stability, an indicator of reliable operation over the life of the system.

- The MOSFET's body diode is highly degradation resistant. In many cases, this can eliminate the need to use an external diode.

- A short-circuit current survival capability that's comparable to IGBTs.

- A very flat RDS(on) curve across a junction temperature range of 0 to 175°C.

- Robust resistance to avalanche conditions.

These characteristics simplify the transition to SiC-based designs and eliminate the complex two-level driver topologies normally required for super-duty IGBTs.

For all their advantages, most SiC devices have some unusual characteristics (such as depletion-mode operation) that can make designing with them a challenge at first. To make the transition to the new devices easier, Microchip offers a family of AgileSwitch digital programmable gate drivers that allow its SiC MOSFETs to be driven almost as if they were IGBTs. The gate drivers are available as discrete devices or co-packaged with the high-voltage SiC MOSFETs in standard or custom power modules.

Development Tools

Microchip further simplified the process of transitioning to SiC by providing Spice simulation models that are compatible with Microchip’s MPLAB Mindi analog simulator. The company’s Intelligent Configuration Tool (ICT) enables designers to model efficient SiC gate-driver settings for its AgileSwitch family.

Availability

The 1700-V SiC MOSFET die, discrete, and power modules are available now in a variety of package options. For information including pricing, call 888-624-7435, or visit Microchip’s website.

Three-Phase MOSFET Gate-Driver IC for BLDC Motors Stretches Battery Life

TRINAMIC Motion Control, now part of Maxim Integrated Products Inc., introduced the TMC6140-LA, a fully integrated three-phase MOSFET gate driver that simplifies design and maximizes battery life of brushless dc (BLDC) motor drives. The TMC6140-LA integrates all three bottom shunt amplifiers to provide a complete motor-drive solution that consumes up to 30% less power and requires roughly half the external components, when compared to similar competing solutions.

The TMC6140-LA is optimized for performance over a wide voltage range, suiting it for servo motors, brushless motors, and permanent-magnet synchronous motors. The three-phase gate driver is equipped with pins to add a charge pump, statically stabilizing the gate voltages of external MOSFETs in three-phase motors with up to 100 A of coil current.

Offered in a 36-pin quad-flat no-leads (QFN) package, the gate driver is a flexible solution offering 0.5- or 1.0-A gate-driver current for 5- to 30-V dc battery-powered applications, such as power tools where voltages can drop below 10 V. Integrated current-sense and diagnostics features add functional safety while simplifying design.

Key Advantages

- Simple design and small size: The TMC6140-LA integrates three bottom shunt amplifiers for current sense and diagnostics, as well as a switching regulator, simplifying design and reducing component count by 50% compared to similar solutions.

- Longer battery life: For applications at 15 V or lower, the switching regulator output can be used to stabilize the power supply, which maintains the output signals to ensure consistent operation over an extended battery life.

- Enhanced diagnostics: Integrated shunt amplifiers provide current sensing for status information. An analog programmable short detection and diagnostic output reports status back to the host.

Availability, Pricing, and Additional Information

The TMC6140-LA is available for $2.68 (1000-up, FOB USA) from Trinamic authorized distributors. The TMC6140-EVAL evaluation board and TMC6140-EVAL-KIT evaluation kit with both bridge and driver evaluation boards cost $66 and $130, respectively.

To order the TMC6140-LA gate driver or learn more, visit https://bit.ly/TMC6140-LAProduct. To order the TMC6140-EVAL evaluation board or learn more, visit https://bit.ly/TMC6140EVAL.

Bipolar Junction Transistors in DPAK Boost Reliability in Automotive and Industrial Apps

Nine new MJD series bipolar transistors from Nexperia all come in the thermally and electrically advantageous DPAK package to cover applications from 2 to 8 A, rated from 45 V up to 100 V. The new parts are pin-compatible with other DPAK-packaged MJD devices, also offering significant reliability benefits.

Available as automotive-qualified AEC-Q101 devices and industrial-grade parts, the new MJD series transistors are rated at 2 A, 50 V (MJD2873/-Q); 3 A, 100 V (MJD31CH-Q); 4 A, 45 V (MJD148/-Q); and 6 A, 100 V (MJD41C /-Q and MJD42C /-Q). The MJD31CH-Q is designed as high gain version. All parts offer class-leading DPAK package reliability performance with an industry-standard footprint. The bipolar transistors suit a wide range of applications such as LED automotive lighting, backlight dimming in LCD displays, linear voltage regulators, relay replacement, motor drives, and MOSFET drivers.

For more information, including product specs and datasheets, visit www.nexperia.com/products/MJD. You can also view this new technology in action at Nexperia’s Power Live Event, held online from September 21-23.

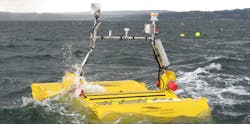

Can Wave Energy Harvesting Help Create "Smart Oceans"?

Until recently, powering the vast fleet of ocean-monitoring buoys and autonomous sensing vehicles used by scientists and offshore industries has been one of the biggest challenges faced by marine engineers. The solar and wind collection systems currently in use provide relatively small amounts of power and are vulnerable to damage from the elements.

However, the marine power shortage may be over soon thanks to Columbia Power Technologies Inc. (C-Power), based in Corvallis, Ore., and its design partner Vicor, based in Andover, Mass.

Harvesting Ocean Energy on the Kilowatt Scale

C-Power's new ocean-wave-energy autonomous offshore power systems (AOPS) capture mechanical wave energy and convert it into usable power at the kilowatt scale, far higher than existing standalone sources. Until now, power for higher-power marine applications was generated using expensive, cumbersome, non-rechargeable onboard batteries or subsea electric tethers fed from a ship or diesel generator.

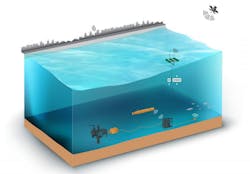

Now that it’s been successfully used as part of a DARPA project called Wave Energy Buoy Systems (WEBS), the company hopes to use it to develop many new forms of offshore monitoring and communication services for a wide range of scientific, industrial, and military applications. This includes underwater vehicles, subsea operating equipment, and open-ocean sensors used to collect environmental data. In addition to being an autonomous and environmentally friendly, the ocean-borne power source also is capable of doubling as a communications conduit.

Scaling Up Power, Efficiency and Adding Data Communication

The latest AOPS platform, known as the SeaRAY, is a scaled-up version of the original design, intended to be a building block for systems that generate 10 W to 1 MW. The SeaRAY AOPS design achieves a high power-to-weight ratio, in part, thanks to power conversion technology from Vicor Corp. The small design footprint enhances mobility and commercial viability, making SeaRAY easier to deliver and set up, saving tens of thousands of dollars in daily operating costs.

The SeaRAY design also makes autonomous, remote data communications possible by transmitting what happens in the ocean to the cloud in real-time. Previously, marine data-gathering systems have been limited in the breadth and frequency of data collection. By using cellular networks and satellite communications to pass data in real-time between the cloud and the SeaRAY, richer data can be collected and delivered more often (see figure above).

Lee Goldberg also has written a feature that digs further into the technology powering the SeaRAY platform. Check it out here.

And click here to learn more about SeaRAY and wave power.

High-Power IGBTs in TO-247-3-HCC Packages Boost Isolation Voltages, System Reliability

The TRENCHSTOP 5 WR6 family of IGBTs developed by Infineon Technologies is targeted at high-power industrial applications, such as power factor correction in air-conditioning systems and welding machines. The new series, available in 20- to 70-A current ratings, achieve best-in-class performance—they’re housed in TO-247-3-HCC packages for improved resistance against contamination and condensation.

The switches have very low conduction losses (30 A, 1,45 V at 25°C) as well as extremely low switching losses (30 A, 1,55 mJ at 175°C). They feature a very low saturation voltage (VCE(sat)) of 1,45 V and a monolithically integrated diode with optimized forward voltage for the target applications to provide high performance while enabling a low BOM cost. The devices are designed to be virtually plug-and-play replacements for previous technologies, such as the company’s TRENCHSTOP 5 WR5 and HighSpeed 3 H3 devices, as well as competitors’ IGBTs with similar voltage and current ratings.

The new TO-247-3-HCC housing of the WR6 family increases the creepage and clearance distances, thus improving the isolation voltage rating. With this, the product family enables more reliable system designs that are resistant against contamination and condensation, e.g., ac outdoor units. The TRENCHSTOP 5 WR6 reduces the total cost of ownership with less failure rate while enabling higher switching frequency in application.

The discrete TRENCHSTOP 5 WR6 family can be ordered now. Additional information is available at www.infineon.com/wr6.

Read more from the Power Management Series: This Week in PowerBites