This article is part of the This Week in PowerBites Library Series.

What you’ll learn:

- At least two advanced power-supply controllers will adopt mixed-signal control architectures to deliver enhanced performance and lower power consumption.

- An open-source EV charge point protocol stack promises to accelerate development of EV chargers while supporting seamless multi-operator transactions.

- New in-package magnetics technology enables higher power densities, more compact solutions.

- It's still not too late to submit your proposals for APEC 2025's Industry Session topics.

The LF Energy open-source project announced the release of LF Energy CitrineOS 1.3.0, the latest version of an Open Charge Point Protocol (OCPP) 2.0.1-compliant Charging Station Management System (CSMS). The standard enables intelligent and efficient management of charging stations, while optimizing energy use and cost.

This new release adds features that improve interoperability between cars, charging stations, and payment methods, ensuring reliability and efficiency in charging for EV drivers.

Key Features of CitrineOS 1.3.0

CitrineOS 1.3.0 introduces several major new innovations designed to streamline operations and enhance the user experience. The first is support for OCPP 2.0.1 Smart Charging, which enables intelligent and efficient management of charging stations, optimizing energy use and cost.

Release 1.3.0 also introduces support for the OCPI 2.2.1 protocol. The Open Charge Point Interface (OCPI) protocol allows for interoperability between charging networks and eMobility operators, making it easy for users of one mobile app to access charging stations from multiple charging networks. The backend of eMobility operators’ mobile apps will use this protocol to communicate with CitrineOS.

Its main features include:

- Registration (Credentials & Versions) to simplify the onboarding process for new eMobility partners.

- Charge Detail Records (CDRs) to enhance tracking and reporting of charging utilization.

- Charging profiles to enable smart charging enhancements during charging sessions.

- Remote management commands (Start, Stop, and Unlock Connector).

- Locations (Push & Pull) to share charging station location details with eMobility operators.

- Sessions (Push & Pull) to give operators real-time visibility of session data.

- Tariffs to provide pricing info to eMobility operators that they can share with their customers.

- Tokens to provide secure authorization mechanisms for seamless user access to charging stations.

CitrineOS’s 1.3.0 release also includes an upgraded version of open-source Stackbox’s Payments module, which now includes support for the Stripe payment system and the Scan&Charge feature. As a result, CitrineOS can provide QR codes to charging stations that, when scanned, send the user to a Stripe payment portal.

For more information about CitrineOS 1.3.0, click here.

Nexperia recently released 650-V ultra- and hyperfast recovery rectifiers in D2PAK Real-2-Pin (R2P) packaging. They fit various automotive, industrial, and consumer applications such as charging adapters, photovoltaic (PV) inverters, servers, and switched-mode power supplies (SMPS).

Combining planar die technology with a state-of-the-art junction termination (JTE) design, these rectifiers offer high power density, fast switching times with soft recovery, and excellent reliability. They’re encapsulated in a D2PAK R2P (SOT8018), which offers the same package outline as the standard D2PAK package but has only two pins instead of three (the middle cathode pin is removed). This increases the pin-to-pin distance from 1.25 mm to over 4 mm, which makes it possible to meet the creepage and clearance requirements stated in the IEC 60664 standard.

To learn more about Nexperia’s portfolio of recovery rectifiers, visit here.

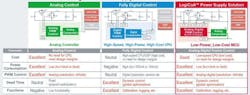

LogiCoA, a new power-supply solution developed by ROHM Semiconductor, targets small- to medium-power industrial and consumer equipment (30 W to 1 kW class). It provides the same functionality as fully digital controlled power supplies at low power consumption and cost equivalent to analog power types.

Analog-controlled power supplies are commonly used in industrial robotics and semiconductor manufacturing equipment that operate in the medium-power range but can have difficulty providing high levels of reliability and precise control. Conversely, while digitally controlled power supplies enable fine control and settings, they tend to suffer from higher power consumption and cost.

To address this issue, ROHM came up with the LogiCoA power solution, an “analog-digital fusion control” power supply that combines a digital control block centered around the LogiCoA MCU with analog circuitry comprised of silicon MOSFETs and other power devices. Capable of supporting designs ranging from 30 W to 1 kW, applications include semiconductor manufacturing equipment, gaming systems, and a wide range of other industrial equipment and consumer products.

The LogiCoA architecture allows for precision control functions typically handled by complex digital controllers such as high-speed CPUs or DSPs to be implemented using a mix of analog circuitry and low-bit, low-power MCUs. Their features include a built-in three-channel analog comparator that can be linked to a timer and digital-to-analog converter that enables digital control of various parameters to support different power-supply topologies.

In addition, both control parameters (such as current and voltage values) and operation log data can be recorded in the MCU's nonvolatile memory.

LogiCoA Power-Supply Reference Design

The REF66009 evaluation reference design offered on ROHM's website enables users to verify the functionality of the LogiCoA MCU. The LogiCoA001-EVK-001 reference board and its included example software makes it possible to test and confirm the sequence control of execution tasks. For more information on the reference board, please contact a sales representative or the contact page on ROHM’s website.

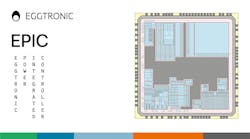

The latest series of Eggtonic's EPIC integrated power controller ICs include on-chip reprogrammable flash memory to help OEMs reduce inventory by allowing the same low-power, mixed-signal IC to be deployed across multiple applications.

Like previous EPIC (Eggtronic Power Integrated Controller) devices, the EPIC 2.0 flash series is designed to optimize performance and low-load to full-load efficiency, minimize standby power consumption, and reduce component count and form factor in high-performance power-converter and wireless-power-transmission systems.

Built around a 32-bit RISC-V core and a rich set of high-performance digital and analog peripherals, EPIC 2.0 Flash ICs feature a flexible internal structure that supports control of both standard and proprietary power conversion architectures. These devices can be used in a wide range of consumer and industrial applications, including USB-PD and Qi charging, AC-DC and DC-DC power supplies, motion control, lighting, and wireless power transmission at ratings up to 10 kW.

Using the new EPIC devices, engineers can deliver efficiencies of up to 96% while having the flexibility to deploy proprietary firmware, adapt firmware libraries at any stage of development, accommodate changes to industry standards, and easily test various design options during prototyping.

The EPIC2ATxxx flash version is seamlessly compatible with all Eggtronic firmware developed for the existing EPIC2ACxxx OTP version, so that customers and OEMs can select the memory best suited for their applications and needs. A library of programming tools and detailed datasheets are available on request.

The Model SSD Shunt Sensor - series of digital DC shunt-based current sensors from Bourns Inc. offers superior accuracy, stability, and electrical isolation over a wide −40 to +115°C operating temperature range. These small and highly integrated digital system-in-package (SiP) devices are well-suited for a wide variety of battery-related current sensing applications. These include large-scale energy-storage banks, renewable-energy generation infrastructure, industrial motor drives, building automation systems, and EV charging stations.

The series features a 16-bit automotive-grade microcontroller and delivers accuracy of ±0.1% full scale. The internal 24-bit analog-to-digital converter (ADC) offers plug-and-play simplicity. This helps streamline implementation so that engineers can quickly add high-accuracy current measurement into their latest designs or retrofit it into existing ones.

These shunt-based sensors also eliminate the need for periodic device calibrations, all while providing highly accurate measurements that contribute to more efficient use of power. There are two models: the RS-485 serial interface model, which can also be configured as MODBUS RTU, and the customizable CANbus model. The Model SSD Shunt Sensor – Digital Series is available now.

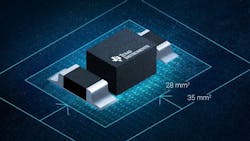

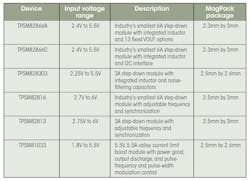

Texas Instruments introduced six new power modules designed to improve power density, enhance efficiency, and reduce EMI. These power modules leverage TI’s proprietary MagPack integrated magnetic packaging technology, shrinking their size by up to 23% compared to competing modules. As a result, designers of industrial, enterprise, and communications applications are able to achieve previously impossible performance levels.

In fact, three of the six new devices, the TPSM82866A, TPSM82866C, and TPSM82816, are the industry’s smallest 6-A power modules that offer a power density of nearly 1 A per 1 mm2 of area. (For more information, see TI.com/powermodules.)

Packing More Power into Smaller Spaces

All of these modules use MagPack, TI’s exclusive 3D package molding and packaging technology to create magnetic solutions that make the best use of the height, width and depth of the power modules to push more power in a smaller space.

The magnetic packaging technology includes an integrated power inductor with proprietary, newly engineered material. As a result, engineers can now achieve best-in-class power density and reduce temperature and radiated emissions while minimizing both board space and system power losses.

Preproduction quantities of TI’s new power modules with MagPack packaging technology are available for purchase now on TI.com. Evaluation modules are also available, starting at US$49.

To learn more, check out the technical article, “MagPack Technology: Four Benefits of new power modules that can help you pack more power in less space.”

Kyocera AVX expanded its line of KAM Series automotive MLCCs with the addition of 20 new components. Manufactured using miniaturization and high-capacity atomization technologies, KAM Series automotive MLCCs are available in an extensive range of case sizes, capacitance values, and voltage ratings optimized for use in small, densely packed automotive circuits with fast processing speeds.

These compact and lightweight surface-mount components minimize board space requirements and deliver capacitance values high enough to reduce capacitor component counts in electric vehicles, ADAS, and ADS designs.

KAM Series automotive MLCCs are compliant with the AEC-Q200 Stress Test Qualification for Passive Components standard, manufactured in IATF, QS9000, and VDA 6.4-approved facilities. They’re continuously tested in quality assurance (QA) laboratories to ensure superior quality and performance. QA methods include 100% visual inspection, increased sampling for accelerated wave soldering, and lot-by-lot reliability testing.

The new releases are available in four case sizes (0201, 0402, 0603, and 0805) with thicknesses extending from 0.33 to 1.45 mm, nickel/tin terminations, two dielectrics (X7R and X7T), four voltage ratings (4, 6.3, 10, and 16 V), capacitance values extending from 0.1 to 22 µF (±10%), and 7-in. reels loaded with paper or embossed plastic tape.

That expands the full range of the KAM Series automotive MLCCs to include nine case sizes (0201, 0402, 0603, 0805, 1206, 1210, 1808, 1812, and 2220), two termination styles (nickel/tin and FLEXITERM), six dielectrics, 16 voltages extending from 4 to 3,000 V, and capacitance values extending from 0.5 pF to 22 µF.

For more information about Kyocera AVX’s new KAM Series automotive MLCCs, click here.

The AOZ71137QI from Alpha and Omega Semiconductor (AOS) is a three-rail, seven-phase controller engineered as a multiphase core voltage (Vcore) power-management system solution. Delivering the industry’s lowest quiescent power in a multiphase controller, according to AOS, the AOZ71137 is designed to meet Intel IMVP 8, 9, 9.1, and 9.2 specifications. When paired with AOS’s benchmark DrMOS and Smart Power Stage (SPS), this combination of devices provides a complete power-delivery solution for Intel Meteor Lake and Arrow Lake notebook platforms.

The AOZ71137 digital controller is designed with AOS’s Advanced Transient Modulator (A2TM), an advanced, variable-frequency, hysteretic peak-current-mode controller with a proprietary phase-current sensing scheme. With the control provided by the A2TM feature, designers are able to implement fast transient response and optimal current balance for both transient and DC load.

In addition, the AOZ71137 provides complete protection and warning features, including UVP, OVP, OCP, and OTP. Fault-protection behavior can also be easily programmed through SMBus. AOS’s Vcore solution offers real-time telemetry information via its SMBus for VIN, VOUT, temperature, output currents, power states, and PSYS/VSYS/IAUX pins reporting through the SMBus.

Technical Highlights

- AOS Advanced Transient Modulator (A2TM) control scheme: Variable-frequency, hysteretic, peak-current-mode control ensures fast transient response and dynamic phase current balance.

- Three output rails up to 4 + 2 + 1 phases.

- SVID interface to CPU compliant with IMVP8, 9, and 9.1/9.2 specifications, support Fast V-Mode to protect CPU.

- Low quiescent current: 3.7 mA at PS0 for 2 + 1 + 1 configuration.

- Autonomous phase management, including phase shedding and auto DCM to optimize power loss.

- FCCM/FCCM2 pins to lower power loss in power-saving mode for notebook applications.

- Supports multi-sourced industry-standard DrMOS and SPS power stages.

- User-friendly GUI for compensation and configurations with minimal external RC components.

- EC programmability for configurations with built-in MTP and RAM with more than 10x configuration changes.

- Acoustic noise suppression QFN 6x6-52L package.

Pricing and Availability

The AOZ71137QI is immediately available in production quantities with a lead time of 12 to 16 weeks. Unit pricing starts at $2.4 in 1,000-piece quantities.

According to FCL Components America Inc., it’s released the smallest, low-power, automotive-grade, PCB-mounted relay—the FBR53-LE. Because this relay is more than 2 mm lower in height than others in its class, it helps enable more compact designs.

The FBR53-LE relay is a 1 Form U (Form A with twin contacts) device, measuring 15.7(L) × 12.3(W) × 14(H) mm, with a volume of 2,704 mm3. Its maximum carrying current is 54 A for 1 hour, and its maximum inrush current is 200 A. Contact rating is 14 V DC, 40 A, and nominal coil power is 640 mW. Its operating temperature ranges from −40 to +125°C, making it an ideal fit for engine compartments.

Samples are available now. Click here to access a datasheet.

APEC 2025, to be held from March 16-20 in Atlanta, Georgia, has put out a call for submission of proposals for the conference’s popular Industry Session series. The Industry Session component of the conference is intended to encourage cutting-edge content from industry practitioners. Industry Session (IS) speakers are invited to make a presentation only, avoiding the formality of writing the papers for IEEE Xplore publication. IS tracks run in parallel with APEC Technical Sessions and the presentations are included for download by paid APEC attendees.

The deadline for submission of proposals is August 23rd.

Industry Session proposals may be submitted for an individual speaker presentation or for an overall session proposal. The total time allowed for each presentation is 25 minutes, including 5 minutes for Q&A. To submit a proposal for an Industry Session at APEC, presenters should prepare a two- to three-page proposal that provides a summary of the presentation content and a description of the target audience. Also, a short professional biography of the speaker should be included.

If proposing for a full session, a proposal for each of the individual presentations must be submitted. Presentations should have strong technical content and commercial references should be limited and only in support of the core content.

“Topics of interest for Industry Sessions cover a very broad range of technologies and disciplines,” reported David Chen, Industry Session Co-Chair. “The important element is that these presentations reflect the very latest in technology commercialization.”

About the Applied Power Electronics Conference (APEC)

Dubbed “The Premier Event in Applied Power Electronics,” APEC focuses on the practical and applied aspects of the power electronics business. This isn’t just a designer's conference. APEC has something of interest for anyone involved in power electronics:

- Equipment OEMs that use power supplies and dc-dc converters in their equipment.

- Designers of power supplies, dc-dc converters, motor drives, uninterruptible power systems, inverters and any other power electronic circuits, equipment, and systems.

- Manufacturers and suppliers of components and assemblies used in power electronics.

- Manufacturing, quality, and test engineers involved with power electronics equipment.

- Marketing, sales, and anyone involved in the business of power electronics.

- Compliance engineers testing and qualifying power electronics equipment or equipment that uses power electronics.

In addition, APEC is still accepting submissions of Technical Program paper digests for its technical program sessions through August 2nd. Instructions for submissions are available here.

Read more entries in the This Week in PowerBites Library Series.