This article is part of the Power Management Series: This Week in PowerBites

e-Trucks Paving the Way for Greener Highways

Real-World Electric Truck Competition Spurs Innovation, Demonstrates Commercial Viability

The Rocky Mountain Institute's Run on Less – efficiency competition for heavy commercial vehicles concluded this week, with 13 electric trucks having covered thousands of miles on real-world routes. The Run showed that four key trucking segments are ready to go electric now, which together encompass 5.2 million vehicles. If all North American trucks in the four represented market segments went electric, 100 million metric tons of CO2 would be saved every year. The event website has more data from the Run, as well as participant profiles, videos and other stories.

Electric Trucks Charge Forward

Electrification of the world's truck fleets is ramping up as legacy manufacturers such as Freightliner and Volvo work hard to bring products to market in time to challenge Tesla for dominance of this emerging market. But, as Bengt Halvorson's article in Green Car Reports indicates, the electrification of large over-the-road vehicles won't really get underway until there are charging stations dotting the highways that can feed their gargantuan thirst for power. The article takes a close look at some of the early work being done to establish a network of MW-class charging facilities, and some of the technical, logistic, and business challenges they face.

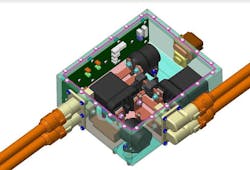

As the article notes, one of the challenges is producing commercial equipment that can supply a megawatt or more to the trucks' hungry batteries. This goal has taken a small but important step toward reality with Sensata Technologies' announcement of its new High Voltage Junction Box solutions. Designed to support up to 850 V and 1,300 A, the dc charging boxes provide safe and reliable protection and power distribution in the megawatt-class charging systems used by medium- and heavy-duty commercial electric trucks.

Combining Sensata’s proven contactor, fuse, and controller technologies into a compact package, the High Voltage Junction Boxes are custom-designed for specific vehicle requirements. To meet current carry and temperature requirements, Sensata’s cooling and temperature control technology directly interfaces to the busbars and provides exceptional cooling efficiency within tight space restraints. For additional safety, Sensata’s isolation monitoring design ensures isolation of high voltage from the chassis. The solutions’ software and controllers are built on the AUTOSAR platform.

To learn more about Sensata’s High Voltage Junction Boxes, visit www2.sensata.com/hvjb.

SiC-quisitions Abound as Semi Makers Double Down on WBG

Qorvo Acquires United Silicon Carbide

Qorvo, a semiconductor maker best known for its RF solutions, recently announced its acquisition of Princeton, N.J.-based United Silicon Carbide (UnitedSiC), a manufacturer of silicon-carbide (SiC) power semiconductors. UnitedSiC has been a pioneer in developing a unique cascode architecture that effectively tames the more unruly characteristics of SiC devices and makes it easier for designers to take advantage of their exceptional efficiency at high power levels and high frequencies.

UnitedSiC’s product portfolio, which currently includes over 80 SiC FETs, JFETs, and Schottky-diode devices, will enable Qorvo to serve the fast-growing markets for electric vehicles (EVs), industrial power, and circuit protection, as well as telecom/server power supplies, variable-speed motor drives, and solar photovoltaic (PV) inverters.

UnitedSiC will become part of Qorvo’s Infrastructure & Defense Products (IDP) business and will be led by Dr. Chris Dries, formerly UnitedSiC’s president and CEO and now general manager of Qorvo’s Power Device Solutions. Dr. Dries said, “Our team is thrilled to expand our SiC portfolio as part of Qorvo and continue to build the business with speed and scale, working to accelerate SiC adoption with the industry’s highest-performance devices.”

onsemi Completes Acquisition of GT Advanced Technologies

onsemi, the company formerly known as On Semiconductor, and a spinoff of the once-legendary Motorola Semi empire, recently completed its acquisition of GT Advanced Technologies (GTAT), a producer of silicon carbide. The press release says that the acquisition will enhance the ability to secure and grow a readily available supply of SiC material to be used for its growing portfolio of advanced power devices. The company plans to invest in expanding GTAT’s manufacturing facilities, supporting research and development efforts to advance 150- and 200-mm SiC crystal growth technology, while also investing in the broader SiC supply chain, including fab capacity and packaging.

"As we move to a carbon-free economy, SiC technology is a key driver to enable zero emissions in high-efficiency electric vehicles, renewable energy, and charging infrastructure. By integrating GTAT, onsemi can now provide end-to-end power solutions from SiC crystal growth to fully integrated intelligent power modules,” said Hassane El-Khoury, president and chief executive officer of onsemi.“ El-Koury declined to explain whether the lack of capitalization in the company's new name was a deliberate choice or a result of recent difficulties with the supply chain for upper-case letters.

Battery & Storage News

Enovix's U.S.-Based Automated Factory Makes First Pre-Production Si-Li-Ion Cells

Enovix Corp. announced that the first battery cells have emerged from its automated factory in Fremont, Calif., marking a major milestone in the facility's path toward commercial production in early 2022. Once in production, the automated plant will produce batteries based on the company's silicon-anode lithium-ion technology and a proprietary 3D cell architecture that offers higher energy density than conventional Li-ion cells while maintaining high cycle life.

“Manufacturing the first cell off of our automated line is proof that we are on track to meet our goal of not only delivering a battery with up to 110% greater energy density, but also we’re on target for commercial production in Q1 2022 and first product revenue in Q2 2022,” said Harrold Rust, Co-founder, President, and CEO of Enovix.

The trial run's success required more than 25 machines that comprise the production line to work in concert. This includes both established Li-ion battery manufacturing equipment, such as electrode fabrication and the majority of battery packaging and formation, as well as the company’s proprietary roll-to-stack cell assembly, a precise, high-speed replacement for conventional Li-ion wound-cell assembly. In addition to producing commercial products, the plant intends to demonstrate the feasibility of upgrading existing Li-ion battery manufacturing lines to produce Si-Li-ion cells by "dropping in" its roll-to-stack production tools.

Three-Company Partnership to Focus on Solid-State Battery Dev for Next-Gen EVs

Factorial Energy (Factorial), Hyundai Motor Co., and Kia Corp. announced that they’re partnering to test Factorial’s novel solid-state battery technology and its integration in Hyundai electric vehicles. The plan includes integrating Factorial's technology at the cell, module, and system levels, performing vehicle-level integration, and co-developing specifications for manufacturing Factorial’s batteries.

Factorial's FEST (Factorial Electrolyte System Technology) products are based on a proprietary solid electrolyte material that improves performance, and is safer, than conventional Li-ion cells. The company reports that the FEST process has been scaled to enable the manufacture of 40-Ah cells that perform at room temperature and provide 20% to 50% greater range. In addition, they can be produced in existing Li-ion battery factories utilizing the majority of existing manufacturing equipment. For additional information, visit www.factorialenergy.com.

New National Lab Tackles Some of Clean Energy's Toughest Challenges

Scientists at the Department of Energy’s Pacific Northwest National Laboratory (PNNL) are exploring a new way to store hydrogen that doesn't require extreme pressures, or having to chill it to within a few degrees of absolute zero. The research, being conducted at PNNL's newly dedicated Energy Sciences Center (ESC), explores how to design and control chemical reactions that allow hydrogen to be added or removed from stable molecules, such as ethanol. These molecules serve as “hydrogen carriers,” literally carrying the hydrogen in their molecular bonds.

But energy storage is just one piece of the clean energy puzzle to be addressed by the researchers. The $90-million, 140,000-square-foot facility will bring together existing and new scientific instrumentation, as well as about 250 researchers from various disciplines, so that their collective capabilities and innovation can focus on the nation’s most pressing energy needs. Researchers at PNNL are combining their strengths in computational science, chemistry, and economics to examine the entire system for chemical hydrogen storage—from the design of new catalysts to the reactors where the chemical processes take place, as well as the end products and applications.

Additional details can be found in the full text of PNNL's press release at https://www.pnnl.gov/news-media/new-90m-pnnl-center-focus-solving-clean-energys-biggest-puzzles.

Sustainable Green Efforts in Action

STMicro's 2027 Carbon Neutrality Pledge Puts Green in Both Bottom Lines

STMicroelectronics has been pioneering sustainable technologies and business practices long before it was fashionable, or even considered economically feasible. When the company began its efforts back in 1997, it was surprised to learn that its investments in efficiency, waste reduction, and elimination of harmful emissions all contributed significant returns to the company's bottom line.

Fast-forwarding to 2021, ST's 24th Sustainability Report shows its sustainability efforts continue to yield a significant ROI while the company remains on target to achieve its commitment to actual carbon neutrality by 2027. Unlike many companies, ST defines carbon neutrality as a function of actual emissions, rather than rely on dubious carbon offsets and other bookkeeping tricks. You can see the metrics the company began using in 2016, and the progress it's made along the way, in the report’s Energy and Climate Change section.

The report offers lots of information about the company's other sustainability efforts, but if you’re in a hurry, the blog post's summary is more digestible. There’s also a video sharing what sustainability means at ST:

Infineon and Rainforest Connection Create Real-Time Wildfire Monitoring System

Infineon Technologies announced a collaboration with Rainforest Connection (RFCx), a non-profit organization that uses acoustic technology, big data, and artificial intelligence/machine learning to protect the rainforests and monitor biodiversity. In this partnership, RFCx will explore the use of Infineon’s gas-sensing technologies to augment the capabilities of its current acoustic listening devices used to monitor and protect vulnerable rainforest ecosystems. This includes monitoring primates, birds, frogs, insects, bats, and other organisms, and protecting against threats ranging from illegal logging to forest fires with this collaboration.

Rainforest Connection uses technology and big data to enable on-the-ground partners to save the world’s most threatened rainforests and habitats. Saving rainforests isn’t only the key to halting climate change, it’s also vital to supporting many of the world’s poorest communities relying on rainforests for food, shelter, and livelihood. Additional details are available in Infineon's press release, and on the Rainforest Network's web site https://rfcx.org/.

Read more from the Power Management Series: This Week in PowerBites