This article is part of the This Week in PowerBites Library Series.

Fast, Flexible, and Free Sim Software Adds Features Geared for Power, Analog Designers

QSPICE, an advanced circuit simulation software platform developed by Qorvo, offers features and capabilities created specifically to give power and analog designers higher levels of design productivity through improved simulation speed, functionality, and reliability. In addition, QSPICE allows designers to simulate complex digital circuits and algorithms.

This unique combination of modern schematic capture and fast mixed-mode simulation makes the tool well-suited for the increasingly complex hardware and software challenges faced by today’s system designers. It’s able to take on complex applications such as developing AI algorithms for EV battery charging, optimizing a pulsed-radar power supply, or evaluating the newest silicon-carbide (SiC) FETs.

QSPICE is available free of charge and offers numerous enhancements over legacy analog modeling tools. Improvements include:

- Complete support for advanced analog and digital system simulations, such as those used in AI and machine-learning applications.

- An upgraded simulation engine that leverages advanced numerical methods and is optimized for modern computing hardware, including a GPU-rendered user interface and SSD-aware memory management, to provide dramatically higher speed and accuracy.

- Reduced overall runtimes and a 100% completion rate, based on Qorvo benchmark tests with a suite of challenging test circuits. This compares to a failure rate of up to 15% with these same test circuits using other popular Spice simulators.

- Availability of a regularly updated QSPICE model library featuring the company’s SiC and advanced power-management solutions, making it easy for customers to evaluate and design with Qorvo power.

QSPICE is available now and is actively supported by Qorvo as well as a robust user community through the company’s QSPICE forum.

Automotive LCD Backlight Drivers for LED Matrices Control, Locally Dim Up to 192 Zones

ROHM Semiconductor's BD94130xxx-M series (BD94130MUF-ME2, BD94130EFV-ME2) of LED driver ICs aimed at automotive LCD backlights provide smart, energy-efficient control of large displays increasingly being used in infotainment and instrument clusters of next-generation vehicles.

In recent years, the advancement of advanced driver-assistance systems (ADAS), together with expanding car infotainment functionality, have prompted a shift toward higher-resolution vehicle displays to improve visibility. As such, LED drivers with a local dimming function capable of turning off only the backlight in dark areas of the LCD improve display screen performance and reduce power consumption.

However, as the number of zones controlled with conventional direct-type LED drivers by a single IC drops below 100, the amount of LED drivers and peripheral components will also increase as automotive displays expand with more zones.

To meet this need, ROHM developed products capable of controlling many more zones than conventional driver ICs, thereby reducing overall component count. The BD94130xxx-M series of matrix LED drivers combines an 8-line switch controller with a 24-channel current driver, enabling control (dimming) of up to 192 zones of mini-LEDs for backlighting with a single IC. In addition, the mini-LEDs in each zone can be independently adjusted by using a local dimming function, contributing to larger-contrast-ratio, lower-power-consumption displays.

For example, with current mainstream 10-in.-class infotainment displays that consist of approximately 600 zones, ROHM’s new products make it possible to operate with just one-fourth of the number of LED drivers compared to existing (48-zone) products, decreasing LED driver mounting area by approximately 84%. This advantage will only increase as screens become larger and the number of zones rises inside next-generation cockpits.

The matrix LED drivers combine a 24-channel current driver with a switch controller that can be divided into eight lines (maximum). The number of switch controller lines can be selected from among three patterns (4, 6, or 8) via register settings. In addition, a built-in feedback control function maintains a constant feedback voltage independent of LED temperature characteristics, reducing thermal design man-hours, along with loss ratio.

"Powerful" 32-Bit USB PD-Capable MCUs Now Support UCSI

STMicroelectronics added a USB Type-C connector system interface (UCSI) library to the STM32Cube software ecosystem for STM32 microcontrollers (MCUs) to accelerate development of USB-C Power Delivery (PD) applications.

The X-CUBE-UCSI is a turnkey UCSI-certified solution with ready-to-use hardware and firmware examples to implement standardized communication utilizing an STM32 MCU as a UCSI PD controller. A customer can simply copy-and-paste these designs, which have been optimized for their bill of materials (BOM).

The software lets the MCU connect to the main system processor and exchange information with the operating system using the UCSI protocol, while controlling the USB-C attachment and PD protocol. The main processor, which can be a system-on-chip (SoC), application processor, or STM32MP microprocessor, acts as the UCSI operating system policy manager (OPM). The PD controller on-board the STM32 MCU performs as UCSI platform policy manager (PPM).

The necessary USB Type-C and Power Delivery (UCPD) peripheral is available in various STM32 MCUs. The lowest-cost variant is the STM32G0 line, which suits it as a low-pin-count companion chip for the MPU dedicated to handling the PD functionality.

The software also allows the STM32 MCU to undergo firmware programming via the main processor, in the production line as well as during the lifetime of the application. The main processor uses the UCSI driver, from Microsoft or available in the Linux community, and associated commands to exchange data with the PD controller. In addition to saving development time, this extends interoperability between USB-C devices to support the latest use cases offered by the technology.

X-CUBE-UCSI STM32Cube expansion software helps developers build a USB PD dual-role power (DRP) application as well as support alternate-mode commands.

Enabling a quick start to development, the USB-certified (TID 8088) Discovery board, STM32MP135F-DK, contains an STM32MP135 as the main application processor, connected to an STM32G071 MCU as the UCSI PD controller. The board also features ST’s TCPP03-M20 USB Type-C high-voltage port-protection IC.

More than 500 standard STM32 MCUs are now available with ST’s UCPD controller peripheral implemented on-chip. To discover all of ST’s MCU-based solutions for USB Type-C and Power Delivery technology, go to www.st.com/en/embedded-software/x-cube-ucsi.html. You can also access STM32 Developer zones with all of the tools and resources in one place at STM32 MCU Developer zone and STM32 MPU Developer zone.

Tiny Common-Drain N-Channel MOSFET Device Targets Quick-Charging Apps

Intended for use in battery protection circuits in lithium-ion (Li-ion) battery packs, Toshiba Electronics’ new 12-V common-drain N-channel MOSFET features a current rating of 20 A. Applications include smartphones, tablets, power banks, compact digital cameras, digital SLR cameras and others the require a compact form factor, low on-resistance (RDS(on)), and highly robust protection circuits that reduce heat generation while charging and discharging.

The SSM14N956L, rated for a 12-V source-to-source voltage (VSSS), leverages the company’s micro-process, successfully implemented in its earlier 13.5-A SSM10N954L device. This ensures excellent low RDS(on) characteristics, as low as 1 mΩ, which limits conduction losses. In addition, the process delivers low gate-source leakage current (IGSS) of ±1 µA (max.), allowing for low standby power consumption. Together, these attributes help extend battery operation between charges.

To fit in the tightly constrained spaces typically found in these applications, the new SSM14N956L is designed as a chip-scale package, known as TCSPED-302701. The dimensions are just 2.74 × 3.0 mm with a typical height of only 0.085 mm.

Compact, Cool-Running MOSFETs Boost Power Density and Efficiency

Several new members of Infineon’s OptiMOS power MOSFET PQFN 2x22 PQFN series feature a small 2-× 2-mm² footprint, helping designers achieve significant space savings and cost reduction. It also facilitates design for applications like synchronous rectification in switched-mode power supplies (SMPS) for servers, telecom, and portable and wireless chargers. Additional applications include electric speed controllers for small brushless motors in drones.

The new OptiMOS 6 40-V and OptiMOS 5 25- and 30-V power MOSFETs combine very low on-resistance (RDS(on)) with high figures of merit (FOMs, QG and QOSS) to enhance dynamic switching performance. They also offer leading-edge silicon technology, package reliability, and thermal resistance (RthJC, max = 3.2 K/W).

Their compact form factor and rationalized pinouts improve system form factor with smaller, more flexible geometric outlines for end-user applications. The MOSFETs help usher in reliable system design with less need for paralleling, significantly reducing space and system cost.

The OptiMOS 6 40-V power MOSFET (ISK057N04LM6) with 5.7-mΩ RDS(on) and OptiMOS 5 25- and 50-V power MOSFETs (ISK024NE2LM5) and (ISK036N03LM5) with 2.4 mΩ and 3.6 mΩ RDS(on), respectively, can be ordered now.

GaN Chipset Supports 3,200-W “Titanium Plus” Power Solution for AI, Edge Computing

Navitas Semiconductor’s CRPS185 3,200 W “Titanium Plus” server reference design meets the increasing power demands of AI data centers while also surpassing the EnergyStar standards' stringent 80Plus Titanium efficiency requirements.

The reference design was developed in response to the rapid emergence and deployment of power-hungry AI processors like NVIDIA’s DGX GH200 “Grace Hopper,” which can consume up to 1,600 W/device. That, in turn, can drive power-per-rack specifications from 30 to 40 kW up to 100 kW per cabinet.

The CRPS185 uses the latest circuit designs, including an interleaved CCM totem-pole PFC with full-bridge LLC. The critical components are Navitas’ new 650-V GaNFast power ICs that has a high-speed integrated GaN drive to address the sensitivity and fragility issues associated with discrete GaN chips.

According to the company, its reference designs, enabled by GaNFast power ICs, help significantly accelerate customer developments, minimize time-to-market, and set new industry benchmarks in energy efficiency, power density, and system cos,. These system platforms include complete design collateral with fully tested hardware, embedded software, schematics, bill of materials, layout, simulation, and hardware test results.

In this case, the ‘Common Redundant Power Supply’ (CRPS) form-factor specification was defined by the hyperscale Open Compute Project, including Dell, Facebook, Google, Intel, and Microsoft. The CRPS185 platform delivers a full 3,200 W of power in only 1U—40 × 73.5 × 185 mm (544 cc)—achieving 5.9 W/cc, or almost 100 W/in.3 power density, which is a 40% size reduction versus the equivalent legacy silicon approach. It also easily exceeds the Titanium efficiency standard, reaching over 96.5% at 30% load, and over 96% across 20% to 60% load.

Compared to traditional “Titanium” solutions, the Navitas CRPS185 3,200-W “Titanium Plus” design running at a typical 30% load can reduce electricity consumption by 757 kWh, and decrease carbon-dioxide emissions by 755 kg over three years. This reduction is equivalent to saving 303 kg of coal.

In addition to data-center servers, this solution can also be widely used in applications such as switch/router power supplies, communications, and other computing applications.

Current-Shunt Monitors Enable High-Precision Voltage Sensing in EVs

The ZXCT21xQ family from Diodes Inc. is a new series of high-precision current-shunt monitors designed to measure small sense voltages across a wide common-mode voltage range in electric vehicles (EVs). Automotive applications for these single-stage instrumentation amplifiers include current sensing of load/rail currents in brushless-DC (BLDC) motor controllers, e-compressors, high-power DC-DC converters, on-board chargers (OBCs), battery management systems (BMS), ADAS power supplies, and wireless phone chargers.

Low offset voltage (±30 μV) and gain error (±0.5% and ±0.8%) of the zero-drift core (typical ±100 nV/°C) in these devices enable current sensing across the shunt, with maximum voltage drops as low as 10 mV (full-scale). This allows for small-value sense resistors to be used in high-accuracy monitoring of large-magnitude currents, while reducing the power lost during measurement. In addition, the shunts' low quiescent-current consumption (100 μA maximum) also helps to minimize power consumption.

These current monitors have a 0- to 26-V rail-to-rail common-mode sense voltage range (irrespective of supply voltage), enabling both high- and low-side precision current measurement, while its REF pin enables bidirectional current flow measurement. The ZXCT21xQ family has six voltage gain options (50, 75, 100, 200, 500, and 1000 V/V), each with its own unique order number with three accuracy variants.

All devices in the ZXCT21xQ series are AEC-Q100 Grade 1 qualified, manufactured in IATF 16949-certified facilities, and support PPAP documentation. The devices come in industry-standard SOT363 packages and are rated to operate with full accuracy from −40 to +125°C. Pricing is from $0.321 to $0.451 in 1,000-piece quantities.

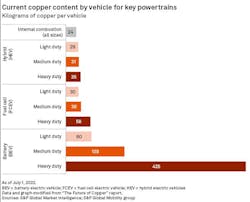

Could Copper Shortages Throttle EV Production?

An article recently published in EE Times raises the possibility that short supplies of copper, and not rare-earth materials, may pose the biggest short-term obstacle to high-volume EV production. While copper is relatively abundant, a combination of a surge in demand and the less-than-convenient locations of most of the world's known copper deposits may make the high-powered motors and wiring harnesses found in modern EVs more expensive to produce.

The article's author says "there are many reasons for the anticipated surge in copper demand. Perhaps most visible are the needs of electric vehicles (EVs), which require much more copper per vehicle compared to internal combustion engine (ICE) vehicles. Then there’s the overall push for increased electrification from top to bottom, including consumer ranges, EV charging stations, and high-voltage transmission lines, and renewable sources like wind farms."

Although global copper production has more than doubled since 1990, the article notes that the present rate of growth may not be enough to keep pace with the accelerating level of demand, which experts predict to spike as high as 20% to 35%.

Read more articles in the This Week in PowerBites Library Series.