This article is part of the This Week in PowerBites Library Series.

What you’ll learn:

- The APEC conference unleashed a deluge of advanced power semiconductors and related passive components.

- Two new electric-motor architectures that feature electrically excited rotors may offer high-performance alternatives to rare-earth-dependent permanent-magnet motors.

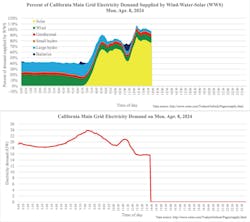

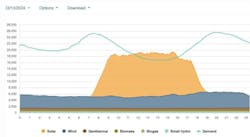

- How California's grid is regularly managing to produce 100% (or more) of the state's energy from wind, solar, and hydro for several hours on most days and is on target to go fossil-free by 2035.

California Sets New Records for Powering its Electric Grid from 100% Renewable Sources

This past month, California set a record for renewable-energy production, giving the U.S. energy sector solid proof that transition to renewable power is not only technically feasible, but also further along than most people believe.

As reported in The Cooldown, April 15 marked the 25th day in the past 32 days that wind, solar, and hydro managed to meet or exceed 100% of the state's energy demand for up to six hours of a given day. While California has briefly produced 100% of its power from renewable on several earlier occasions, this is the first time the state has been able to repeatedly achieve such high performance over an extended period.

The new record, and a detailed analysis of California's shifting energy consumption patterns, was posted on X by Mark Z. Jacobson, a Stanford University professor of civil and environmental engineering. His research has focused on better understanding air pollution and global warming problems and developing large-scale, clean, renewable-energy solutions to them.

The data collected by Jacobsen also showed that during the remainder of the day, when solar energy wasn’t available, the state's wind, hydro, and other renewable-energy sources continued to produce an average of over 6000 MW, roughly a third of the total load.

While Jacobsen acknowledged that California does still rely on a mix of ”dirty” energy and clean energy, he predicted that the state is on track reach its goal of meeting all of its energy need from renewable power sources by 2035.

In addition to marking a milestone toward full sustainability, this achievement helps dispel the common misconception that electric power grids can’t operate reliably with much more than 20% of their power being provided with variable renewable-energy sources.

"In 2009, when we first proposed 100% (Wind/Water/Solar), the utilities and naysayers claimed the grid would go unstable with more than 20% renewable energy, with no evidence," Jacobson wrote on Twitter/X, in the publication Renew Economy. "In 2017, they claimed, with no evidence, a limit of 80%. In 2020, they claimed 90%, then 95%. Now 100% WWS (Wind, Water, Solar) is here to stay."

Further details on this development are available here.

Power MOSFETs Feature High-Speed Body Diode for Improved Efficiency

The TK042N65Z5 and TK095N65Z5 are the first two members of Toshiba Electronics Europe’s new series of 650-V N-channel power DTMOS MOSFETs. Housed in TO-247 packages, these products feature a superjunction structure suitable for switching power supplies in demanding applications such as data centers and power conditioners for photovoltaic (PV) generators.

Both devices use intrinsic high-speed diodes to improve the devices' reverse-recovery characteristics that produce enhanced performance in bridge and inverter circuit applications. The TK042N65Z5 and TK095N65Z5 achieve a 65% reduction in reverse-recovery time (trr) as compared to standard DTMOS VI products, with values of 160 ns and 115 ns, respectively. The new products also reduce the reverse-recovery charge (Qrr) by 88% and drain cutoff current at high temperatures by up to 90% (TK042N65Z5).

Furthermore, the key figure of merit (FOM) of “drain-source on-resistance × gate-drain charge” (RDS(ON) × Qgd) has been reduced by approximately 72% compared with Toshiba’s existing TK62N60W5. All of these improvements reduce power losses of equipment, which helps efficiency.

The TK042N65Z5 and TK095N65Z5 have RDS(ON) values of 42 mΩ and 95 mΩ, respectively. And they’re capable of delivering drain currents (ID) up to 55 A and 29 A. Both devices come in a small TO-247 package.

A new reference design for an upgraded 1.6-kW server power supply is now available based on the TK095N65Z5 device. Toshiba also offers tools that support circuit design for switching power supplies. Alongside the G0 Spice model, which verifies circuit function in a short time, highly accurate G2 Spice models that accurately reproduce transient characteristics are now available.

Qi v2.0-Compliant Reference Design Supports Dual-Pad Wireless Charging with MPP Tracking

Microchip Technology released a reference design for a complete Qi 2.0 dual-pad wireless power transmitter, based on a single dsPIC33 digital signal controller (DSC). A key feature of the new Qi2 standard, recently released by the Wireless Power Consortium (WPC), is the introduction of a Magnetic Power Profile (MPP) with support for magnetic alignment between the transmitter and receiver. The DSC's flexible software architecture enables the support of a combination of MPP and Extended Power Profile (EPP) of Qi 2.0 with one controller.

As it integrates several of Microchip’s automotive-qualified parts, the dual-pad charger reference design meets automotive standards for reliability and safety. The automotive-grade hardware and software solution enables easier automotive integration with support for Automotive Open System Architecture (AUTOSAR) and AUTOSAR Microcontroller Abstraction Layer Architecture (MCAL), functional safety, and more. It also uses integrated CryptoAuthentication to meet the Qi standard's stringent authentication requirement.

Key features include:

- Dual-pad transmitter supporting Qi 2.0

- MPLA and Q-FOD

- Thermal power foldback and shutdown

- Transmitter based on fixed-frequency topology control to optimize EMI/EMC performance

- Easy integration into automotive environments with CAN FD hardware/software

- dsPIC33 capable of integrating near-field communication (NFC) for card detection/protection and communication

- UART-USB communication and GUI for advanced reporting/debugging of data packets

- Hardware reconfigurable and capable of supporting most transmitter topologies

Microchip can deliver design files and software aimed at creating an easy design experience and first-pass success. The design includes the dsPIC33 DSC and a TA100/TA010 Trust Anchor secure storage subsystem.

The design also includes Microchip’s ATA6563 CAN transceiver, MCP14700 gate drivers, and MCP16331 and MCP1755 regulators.

100-V Trench Schottky-Rectifier Diodes Offer Increased Efficiency and Power Density

Addressing the need to boost efficiency in high-frequency power converters, STMicroelectronics developed a new series of 100-V trench Schottky-rectifier diodes. Such devices are typically used in power supplies for telecom, server, and smart-metering equipment, as well automotive LED lighting or low-voltage DC-DC converters. The family comprises 28 variants, with eight current ratings (1 to 15 A), multiple surface-mount packages, and in industrial and automotive grades.

Raising power-converter operating frequency, which is encouraged by the minimal switching losses of technologies like wide-bandgap semiconductors, allows designers to set new benchmarks in power density. However, at elevated frequencies, the energy losses in conventional planar diodes, including silicon Schottky devices, used as rectifiers become a significant factor limiting conversion efficiency.

ST’s trench Schottky diodes significantly reduce the rectifier losses, with forward-voltage and reverse-recovery characteristics that enable increased power density with high efficiency. The forward voltage is 50 to 100 mV better than in comparable planar diodes, depending on current and temperature conditions. Simply changing to these devices can increase efficiency by 0.5%, according to the company.

The industrial-grade parts target applications such as miniature switched-mode power supplies and auxiliary power supplies for telecom, server, and smart-metering equipment. In automotive, typical uses include space-constrained applications like LED lighting, reverse-polarity protection, and low-voltage DC-DC converters. The parts are AEC-Q101 qualified, manufactured in PPAP-capable facilities, and specified from −40 to 175°C.

When combined with ST’s flyback and buck-boost converters, such as the VIPer controllers and HVLED001A offline LED driver, the Schottky rectifiers fulfill the active-components bill of materials for switched-mode power supplies. All are supported in ST’s eDesign Suite Rectifier Diodes Simulator, which helps select the rating and footprint, simulate waveforms, and estimate power efficiency.

The diodes are 100% avalanche tested in production to ensure device robustness and system reliability. They are available in DPAK as well as SOD123 Flat, SOD128 Flat, SMB Flat, and PSMC (TO227A) surface-mount packages.

All devices are in production now. Pricing starts at $0.107 for the 1=A STPST1H100ZF in SMD123 Flat.

Industry’s First 2-A Schottky Rectifiers in DSN1406 Package are Smallest in Class

Diodes Inc. recently unveiled its SDT2U30CP3 (30 V/2 A), SDT2U40CP3 (40 V/2 A), and SDT2U60CP3 (60 V/2 A) high-current trench Schottky rectifiers. Housed in a chip-scale package (CSP) that occupies only 0.84 mm2 of board space, they can be employed for a variety of different purposes, serving as blocking or reverse-polarity protection diodes, boost diodes, and switching diodes.

The compact devices address the stringent design requirements for smaller and more efficient portable, mobile, and wearable devices with the highest current densities in their class, low forward voltage drop, and high thermal resistance.

According to Diodes Inc., the trio are the first-ever 2-A trench Schottky rectifiers to be designed into the X3-DSN1406-2 package with a typical profile of 0.25 mm, occupying a PCB footprint that's less than 4% of a similar SMB-packaged device. These ultra-thin CSPs also feature a short thermal path for enhanced power dissipation, lower thermal bill-of-materials costs, and increased system reliability.

Their ultra-low forward-voltage performance, typically 480 mV (580 mV for the SDT2U60CP3), minimizes power losses, while their avalanche capability ensures robustness under transient voltages and other extreme operating conditions.

The SDT2U30CP3, SDT2U40CP3, and SDT2U60CP3 rectifiers are available at unit prices of $0.16, $0.17, and $0.19, respectively, in 2,500-piece quantities.

Compact SMT Transformers Aimed at Gate-Driver Applications

Two automotive-grade additions to TDK Corp.’s EPCOS InsuGate series (B78541A) of compact SMT transformers support high working voltage. They’re suitable for IGBT and MOSFET gate-driver applications in e-mobility (qualification according to AEC-Q200 as well as the AQG vibration profile) and in industrial electronics. With a low coupling capacitance of only 4 pF, the SMT transformers also suit SiC or GaN semiconductors.

The transformers' manganese-zinc (MnZn) ferrite cores are designed for operating frequencies of 100 to 500 kHz and operating temperatures of −40 to +150°C. Depending on the type, the transformation ratios of the windings are 1:1.08 (B78541A2467A003) or 1:1.07:0.6 (B78541A2492A003). Combining the highly resistive plastic material with a CTI ≥ 600 and the special coil design, shorter clearances and creepage distances are possible compared to conventional insulated or potted components, despite dimensions of only 13.85 × 10.5 × 9.2 mm.

With a partial discharge extinction voltage of at least 840 V (peak voltage) and AC high-voltage testing at 3 kV (50 Hz, 1 s), the 2-g lightweight components meet IEC 61558 for reinforced insulation at working voltages up to 300 V (AC) or 700 V (DC) for basic insulation. This is sufficient for many industrial and automotive applications.

The new UI7 family includes two reference models to enable possible winding configurations for forward and push-pull topologies with the appropriate number of outputs.

Primary applications include:

- Switched power supplies (bridge topologies)

- Gate-driver circuits

- Isolated DC-DC converters

- Galvanically isolated single-channel IGBT driver ICs

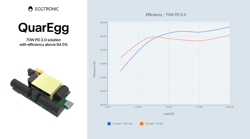

AC-DC ZVS Flyback Architecture Meets Euro Standards for Non-PFC Operation Up to 70 W

Eggtronic’s “QuarEgg” ZVS flyback family of high-density power-conversion solutions has a new member: Built around the company’s patented and proven low-loss, forced zero-voltage-switching (ZVS) flyback architecture, this 70-W version of QuarEgg delivers efficiencies of over 94.5% across the full-no-load to full-load range. Its ultra-high-efficiency architecture increases the power output available to designers before they’re required to implement power factor correction (PFC).

The latest QuarEgg design is based on Eggtronic’s EPIC QuarEgg IC, a mixed-signal, low-power controller. The controller's ability to support multimode operation and synchronous rectification control allows it to perform primary-side regulation without the need for an optocoupler. Measuring only 5 × 5 mm, this device also incorporates an optimized low-power mode for enhancing performance at zero and light loads, and it provides built-in protection against overvoltage, overcurrent, brownout, and extreme temperatures.

The new design complies with the European standard EN61000-3-2, which requires that PFC is required for any power supply rated above 75 W. Now, with the latest evolution of Eggtronic’s QuarEgg, engineers can develop solutions that support 70 W, making non-PFC designs available to applications that might previously have required correction.

Using the architecture, designers can significantly reduce total operational losses when compared to conventional active-clamp-flyback (ACF) and quasi-resonant (QR) topologies, simplify overall circuit design and thermal management, as well as reduce component count, form factor, and cost.

A demonstration board based on the new technology, provides a 70-W output power in a form factor of just 72.6 × 39.1 × 17.5 mm. Smaller form factors will be possible using the architecture, targeting applications such as chargers for portable equipment, set-top boxes, routers and Bluetooth speakers, IoT and small consumer devices, and high-brightness LED lamps.

For further information, click here.

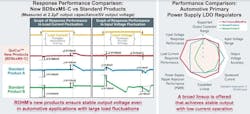

Automotive Primary LDOs Offer Superior Load-Response Characteristics

The BD9xxM5-C series of 45-V-rated, 500-mA output primary LDO regulators (BD933M5EFJ-C, BD950M5EFJ-C, BD900M5EFJ-C, BD933M5WEFJ-C, BD950M5WEFJ-C, BD900M5WEFJ-C) address the growing need for efficient, robust power supplies to support automotive electronic control units (ECUs) and other subsystems that operate from vehicle batteries. Developed by ROHM Semiconductor, the devices are suitable for a wide range of automotive applications, such as ECUs that operate on vehicle primary power-supply systems, including:

- Powertrain: Fuel injection, tire pressure monitoring system

- Body systems: Body control modules

- Infotainment: Instrument clusters, head-up displays

The BD9xxM5-C incorporates original QuiCur high-speed load-response technology that delivers rapid load-response characteristics to current fluctuations. It helps automotive designers create electronics that operate reliably despite the vehicle’s lead-acid, battery-based power system, which is often subject to sudden voltage fluctuations.

For example, the LDO can maintain output to within 100 mV of set voltage even as the load changes between 0 and 500 mA in 1 μs (rise time/fall time). Furthermore, low 9.5-µA (typical) current consumption contributes to lower power consumption in automotive applications.

These new products will be available in four packages, ranging from the compact HTSOP-J8 to the high-heat-dissipation TO252 (TO252-3/TO252-5) and HRP5 types. This allows users to select the most suitable package for each use case.

Support Tools

ROHM Real Models are high-accuracy Spice models that utilize original model-based technology to faithfully reproduce the electrical and temperature characteristics of the actual IC, resulting in a perfect match between the IC and simulation values. This ensures reliable verification, contributing to more efficient application development, such as preventing rework after prototyping.

Two New Electric-Motor Architectures: Revolutionary? Evolutionary? Or Something Else Entirely?

It's always rewarding when one of our readers shares a new technology or design insight they've created. That’s just what Fred Klatt has done with his recent article on a unique motor architecture he's developed. I'd like to invite some of our other knowledgeable readers to share their thoughts on his story.

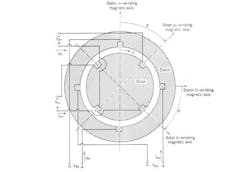

In “Transforming Electric Vehicles: The Doubly-Fed SYNCHRO-SYM Motor,” Mr. Klatt, CEO of Best Electric Machine (BEM), offers an intriguing look at the theory behind a "symmetric, multiphase, wound-rotor ‘synchronous’ doubly-fed" machine. He believes it can offer extraordinary efficiency and offer extremely high performance for its weight and size. The author also says that the architecture lends itself to being manufactured using 3D printer technologies.

The architecture Mr. Klatt describes is intriguing, and the theory behind it may have already been at least partially validated by a new design, recently released by ZF Friedrichshafen AG, one of the world’s largest suppliers of parts to the automotive industry.

The company describes its rare-earth-free "ZF Machine" as an In-Rotor Inductive-Excited Synchronous Motor (I2SM) that incorporates a brushless inductive coupler to energize the rotating element. A deeper explanation of the ZF machine's operation, and its potential impact, can be found in the article "German EV Motor Could Break Supply-Chain Deadlock: Innovative design promises high performance without rare-earth magnets,” recently published on the IEEE Spectrum website.

Both motors appear to share many design features, and they have the potential to be practical alternatives to the permanent-magnet products used in many EVs today. Although I’m a degreed EE, I don't have a deep enough background in EM and motor theory to form a definitive opinion on how similar, dissimilar, or technically feasible either architecture might be, so I'm inviting comments from our knowledgeable readers.

Are there any sharp-eyed, power-savvy, readers who would like to share their take on these unique motor technologies?

Please check out Mr. Klatt's story here and the ZF Machine architecture here and let us know what you think in the comments section. Or write me at lgoldberg(at)green-electronics.com.

Read more articles in the This Week in PowerBites Library Series.