This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- The benefits of thermal interface materials.

- Comparing FR-4 laminate with insulated metal substrate (IMS) PCB.

- How phase-change TIMs may prove to be the best solution.

One of the most important—and difficult—design decisions for circuit designers is creating an optimum heatsink method for high-power devices/systems such as power processors and power supplies. A key area of expertise is the attachment method of an electronic power device to a heatsink or a heat spreader. As power densities increase in power electronics, the thermal interface in between the power module/device and heatsink is now a bigger challenge for designers.

The bottom line is to have a solid thermal contact that will direct most of the heat away from the electronic power devices and on through a heatsink.

Thermal interface materials (TIMs) inserted between the power device and heatsink will greatly improve the thermal path from the device generating that heat to some type of heatsinking device. This method will usually enable adequate cooling of the power device if the heatsink is designed to properly guide that heat away from the power electronic device.

Beware that at very high power densities, TIMs may at some point begin to limit the effectiveness in helping guide the heat away from the thermal source.

TIMs Between Rough Surfaces

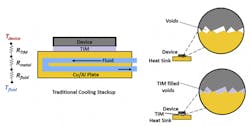

We will find that, at the microscale, most thermal sources and heatsinks will have a rough surface where minute pockets of air can get trapped between the power device and the heatsink (see figure).1

TIMs for Power Modules Between Surface Bowing and Cavities

Modern computer processors have quite high power density. A typical example is a central processing unit (CPU) with a 130-W power consumption on an area of 263 mm2 (a rectangle of 16 mm width and a power density of 0.5W/mm2). A thermal grease TIM was used to enable a solid thermal connection between the processor and the heatsink.

This thermal grease has a melting point of 45°C, at which the material remains as a solid coating under normal handling and storage conditions. However, it will quickly melt during power up of the system to fully wet all contact surfaces.

Unlike thermal grease, which will remain wet and is open to collecting dust or smearing after the application, an optimized phase-change TIM will remain dry-to-the-touch on the completed module before to shipping to the final customer.2

FR-4 vs. IMS PCB with a GaN Inverter

The size and reliability of a power electronics system greatly depends on the proper heat transfer of a power IC to the ambient surroundings. The ubiquitous use of power surface-mount-device (SMD) packages is lowering the component footprint on the printed circuit board (PCB), although the PCB is now used as a major heat dissipation path.

Now the PCB material selection needs a good thermal analysis when comparing an FR-4 NEMA grade designation for glass-reinforced epoxy laminate material with an insulated metal substrate (IMS) PCB.3 This example outlined in the reference examines a three-phase GaN inverter for motor drives. In the final analysis, it was determined that an FR-4 PCB will have a 45% higher average RθJA as compared to an IMS PCB. The TIM choice was selected because of the low mechanical strength of the thin FR-4 PCB.

Phase-Change TIMs

Phase-change TIMs offer a far better alternative to the more traditional thermal-management solutions, such as non-curing thermal pastes or greases.

A phase-change material (PCM) is designed to change state at its phase-change temperature. This means that it will transition from a solid material to a softer, conformable interface above the phase-change temperature. As a result, the product can adapt to the contours of the surface by filling in all voids and small gaps, like the performance of a paste in an application. This will lead to a minimal bond line thickness and thermal resistance at the interface.

Applications that require such an enhanced heat transfer are small electronic devices like mobile smartphones, gaming consoles, and tablets.

Summary

This article defined TIMs and has revealed the benefits and uses of these materials in enhancing the thermal transfer of heat away from electronic devices. A wide range of TIMs are available. One particularly effective example is the phase-change TIM, which provides a very efficient medium for heat transfer away from electronic devices by efficiently morphing its shape between surfaces to provide the best heat transfer medium between two surfaces.

Read more articles in the Power Management Series: Delving Into Power Density

References

1 Thermal Interface Materials: Why TIMs suffer at High Power Density, jetcool

2 The Crucial Influence of Thermal Interface Material in Power Electronic Design

3 Thermal Comparison of FR-4 and Insulated Metal Substrate PCB for GaN Inverter, Texas Instruments