This article is part of the TechXchange: Power Supply Design

Pulsiv, a Cambridge-based startup, announced its new power electronics technology that uses a unique algorithm-based switching technique to convert ac to dc. Now, low-cost flyback architectures can be used at power levels well above the 70- to 80-W limit, which usually requires more complex and costly resonant converters.

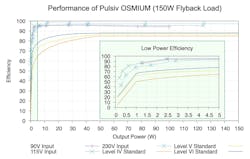

The inductor-less switching architecture eliminates the need for a conventional boost/PFC stage, allows for the use of lower-cost components, and maintains high efficiency down to as low as 2% of rated load (85% at 1%). Furthermore, it eliminates the need for a low-power standby supply for most applications. While the initial reference designs target applications in the 100- to 250-W range, Pulsiv said the technology can be scaled to support much larger applications of 10 kW or more.

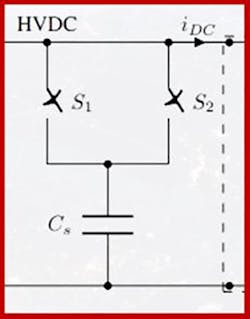

Branded as the Pulsiv OSMIUM switching architecture, it performs highly efficient ac-dc conversion using an application-specific MCU to control two power switches (S¹ and S² in Fig. 1). The switches alternately charge and discharge a small storage capacitor according to an algorithm that smooths inrush and output currents.

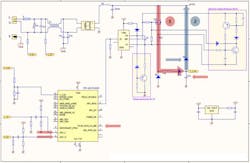

The algorithmic switch (Fig. 2) spreads the converter's ac power input across much more of each cycle, thereby limiting peak currents to levels that keeps the phase of the input current as close to the input voltage phase as possible. This precise control allows it to keep its power factor well within current global eco-label requirements without the bulk and expense of a power-factor-correction (PFC) inductor.

To demonstrate the technology's advantages, Pulsiv designed a universal-input, single-switch, 150-W flyback power-supply design that delivers 97.5% average (99.5% peak) front-end efficiency while maintaining 90% at just 2 W (Fig. 3). A 240-W interleaved flyback is currently being developed and work is underway to showcase reference designs with even higher power capability.

The company said its OSMIUM circuit offers several other advantages. For example, the switch's reduced peak currents allow for the use of much smaller, less costly transformers that shrink the converter's footprint and BOM costs. In addition, the architecture largely eliminates the current spikes that occur in conventional converters, enabling manufacturers to further reduce BOM costs by using transistors, capacitors, and other components with lower voltage margins. Finally, since the converter's critical components operate at low temperatures, they have a much longer expected operating life, even in designs that use convection cooling.

The switching controller also supports several optional smart features that include active bridge control, configurable hold-up, X-cap discharge, HVDC output selection, a power-consumption indicator, and grid-failure detection. These optional features can be selected as required to meet the needs of different end applications.

Since the OSMIUM microcontrollers (PSV-AD-150 and PSV-AD-250 sampling now) don’t directly determine output power, they can be used as a platform for any application requiring 1 W to 10 kW by adjusting only three system components and connecting a suitable dc-dc converter. In addition, the architecture can be combined with commodity flyback dc-dc converters to serve as a lower-cost alternative to LLC solutions.

Engineering samples of the OSMIUM microcontrollers will be available through a network of distribution partners. Pulsiv also will be offering the PSV-AD-250-DS development system that can be used by engineers to evaluate the technology. All that's required to produce a complete power-supply prototype is to add a suitable dc-dc converter.

Additional information about OSMIUM products and technology, as well as full reference designs, can be found by clicking here.

Read more articles in the TechXchange: Power Supply Design