Automotive multilayer ceramic capacitors (MLCCs) cover a wide range of case sizes, capacitance values, and working voltages. A family of such capacitors from Kyocera AVX exhibits that variety—it includes surface-mount and leaded MLCCs as well as surface-mount feedthrough filters.

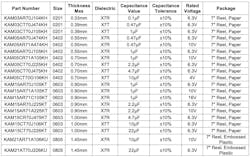

Recently, the company expanded its line of KAM Series automotive MLCCs with 20 new components. The new releases come in four case sizes (0201, 0402, 0603, and 0805) with thicknesses extending from 0.33 to 1.45 mm. Features include nickel/tin terminations, two dielectrics (X7R and X7T), four voltage ratings (4, 6.3, 10, and 16 V), capacitance values extending from 0.1 to 22 µF (±10%), and 7-in. reels loaded with paper or embossed plastic tape.

Applications for the new KAM Series automotive MLCCs include electric vehicles (EVs), automated driver-assistance systems (ADAS), and automated-driving-system (ADS) engine control units (ECUs). The MLCCs will also find homes in powertrains, central gateway (CGW) communication nodes, cluster head-up displays (HUDs), door control units (DCUs), cameras, radar, LiDAR, memory, CPU/MPU decoupling, and other low-voltage safety systems with space constraints and high capacitance demands. Moreover, they’re well-suited for use in high-reliability applications outside of the automotive industry.

With this latest addition, the KAM Series automotive MLCCs are now available with nine case sizes (0201, 0402, 0603, 0805, 1206, 1210, 1808, 1812, and 2220), and two termination styles (nickel/tin and FLEXITERM). FLEXITERM is designed to enhance the mechanical flexure and temperature-cycling performance.

The FLEXITERM layer protects the component from any damage to the ceramic resulting from mechanical stress during PCB assembly or use with end customers. Using FLEXITERM, KYOCERA AVX provides up to 5 mm of flexure without internal cracks. Beyond 5 mm, capacitors will generally fail to “open.” Temperature cycling performance is increased to 3,000 cycles and beyond.KAM Series automotive MLCCs are manufactured using miniaturization technologies developed for smartphones and materials proven to maintain high-reliability performance in automotive environments. They’re optimized for use in small, densely packed automotive circuits with fast processing speeds.

These surface-mount components are said to minimize board space requirements and deliver capacitance values high enough to reduce capacitor component counts. Both of those capabilities are essential to helping automotive engineers overcome some of the challenges posed by evolving EV, ADAS, and ADS designs.

Kensuke Ikeda, Senior Manager – MLCC Development, KYOCERA Corp., said, "The number of MLCCs mounted in circuits related to EV, ADAS, and autonomous-driving systems is steadily increasing, accelerating market demand for miniature components, and the voltage ratings of the ICs employed in these systems is decreasing, driving new demand for low-voltage MLCCs. Our evolving line of KAM Series capacitors satisfy these market demands. For example, when 5 V DC is applied to our 0805 X7R dielectric MLCC rated for 10 V and 10 µF, it maintains 86.3% of its capacitance due to excellent DC bias characteristics."

KAM Series automotive MLCCs are plated with a nickel/tin finish and are compliant with the AEC-Q200 Stress Test Qualification for Passive Components standard. The parts are manufactured in IATF, QS9000, and VDA 6.4-approved facilities, and continuously tested in quality-assurance (QA) laboratories.

According to Kyocera, QA methods include 100% visual inspection, increased sampling for accelerated wave soldering, and lot-by-lot reliability testing. All KAM Series automotive MLCCs are also RoHS-compliant and designed to be operated below the rated voltage.

Read more articles in the TechXchange: Charging Capacitors.