Check out more coverage of DesignCon 2023.

Today, companies are adopting augmented reality (AR) to assist with everything from training technicians, to perform repairs under the hood of a car, to guiding workers through the installation of chip equipment in a fab.

While wearing a headset or looking through a camera, users can view instructions, digital objects, or other images imposed on views of the real world. In some cases, they can even manipulate the scene by using their fingers to grab the corners of a virtual object and drag it to one side. While AR is becoming valuable to a range of industries, the electronics sector is still trying to figure out where it fits.

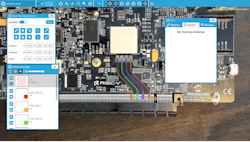

Cadence Design Systems hopes to bring the power of augmented reality to the electronics lab bench. The San Jose, California-based company offers a software tool called “InspectAR” that can display a digital representation of a printed circuit board (PCB) over a real-time view of the physical hardware.

According to Cadence, everyone from electronics engineers in a lab to the technicians on a factory floor can use it to inspect, validate, test, and identify areas for improvement on a prototype circuit board more easily.

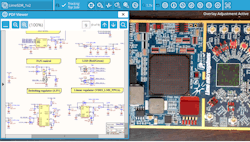

The technology, which Cadence demoed at DesignCon 2023, requires users to upload data from the software tools they used to design the PCB. Instead of viewing the hardware through a headset such as Microsoft’s HoloLens, the prototype is placed under a camera or smartphone. InspectAR overlays the data—everything from the components and pinouts to the nets and layers—on the physical PCB, which users can view via a desktop or mobile device.

By selecting a specific layer of the PCB, users can view whether they made a mistake during the design phase of the project, or whether a fault was introduced while the device was being manufactured. If the circuit board is rotated or flipped over under the camera or smartphone, the data displayed on the device will automatically track with the coordinates of the real PCB, so you can inspect it from any angle.

According to Cadence, you can select any component or connection that belongs on the PCB, and InspectAR can immediately identify where it’s located. Alternatively, you can click on a component to display the design-specific pinout or review datasheets and/or supplier information, saving you from having to constantly check the PCB’s schematics or other documentation.

As the speed of signals continues to increase and more components are crammed closer together, it's becoming more of a challenge to locate points of interest on the PCB and test that everything works before moving a prototype into mass production. According to Cadence, InspectAR can help with that problem by highlighting the right pins and connections on the PCB to probe.

Based on technology that Cadence acquired from a startup of the same name in 2020, InspectAR works with many of the most popular electronic design tools, including those from Altium, Autodesk, and Siemens.

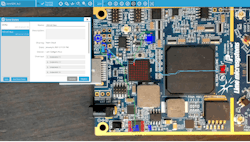

Cadence said several people can access the data in a project at the same time and share real-time views with each other, enabling engineers, technicians, and managers around the globe to easily collaborate.

Users can leave comments on any net or component to prevent confusion during the design project, and they can insert datasheets, documents, or other files for future reference as well as instructions for testing or manufacturing the PCB. Furthermore, users can create markups or other visual aids to pinpoint areas of the physical product where they want to give feedback or propose changes.

While it’s still relatively early in the electronics industry’s use of augmented reality, Cadence’s scale should help it expand InspectAR to more customers and upgrade it with more advanced capabilities.

Before it joined Cadence in 2020, the startup behind InspectAR said that it had already amassed “thousands” of users. The tool also can be accessed on a smartphone via iOS and Android apps.

Check out more coverage of DesignCon 2023.