ENNOVI is a new mobility electrification solutions business focused on the design, development, and engineering of innovative interconnect solutions for battery, power, and signal systems targeting next-generation electric vehicles (EVs). Supported by Blackstone, ENNOVI is a spinoff from the interconnect and mechanical business groups of Interplex, and will be led by Stefan Rustler as CEO.

Committed to serving world’s leading EV brands and manufacturers and helping them reach an electric future faster, the new company will allow Interplex to continue to prioritize the datacom and industrial market with high-precision mechanical solutions and busbar technologies.

According to Stefan Rustler, CEO of ENNOVI, “We are passionate about helping our customers electrify faster. This new chapter gives our mobility business a renewed focus on the automotive industry, allocating the best industry talents to ensure we deliver to the increasing demands of EV manufacturers. In launching ENNOVI, we are at the forefront of the latest technological advancements shaping the industry.”

This spinoff is an indicator of a larger trend of companies repurposing business units and core technologies to better address the growing demand for advanced embedded solutions in next-generation EVs. According to Research & Markets, the global automotive connector industry alone expects a value of US$103.92 billion, at a CAGR of 12.70%, from the period 2023 to 2027. This growth is influenced by things like the expansion of advanced subsystems in cars and growing overall functionality, while addressing safety and reliability in the connected systems.

Ed Huang, COO of Private Equity Asia, Blackstone, added, “We are excited about the creation of ENNOVI, which will focus on mobility electrification, a rapidly growing sector globally and a key contributor to the broader shift towards sustainable energy. ENNOVI is well-positioned to deliver innovative and customized solutions as a long-term strategic partner for its customers. ENNOVI will benefit from Interplex’s 60-year track record and global expertise in customized connector solutions.”

Dr. Ulrich Spiesshofer, Chairman of Interplex and Chairman of ENNOVI, said, “We have formed for ENNOVI a global management team of strong and proven leaders that have decades of relevant industry and technical experience. Under Stefan's leadership and with his global track record of shaping businesses for accelerated growth, ENNOVI will drive customer service excellence as a focused, global mobility solutions business and shape our operations to prosper in one of the fastest growing industrial markets.”

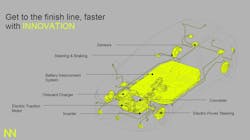

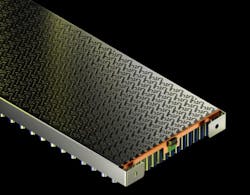

The company intends to leverage its competencies to develop and create complex systems with design-to-specification solutions using technologies such as precision stamping, molding, hot and cold laminating, as well as laser and ultrasonic welding. Cell-PLX, ENNOVI’s customizable battery interconnect system, is an example of the kinds of solutions designed specifically to help EV manufacturers more easily create reliable battery connections. It has a thin, tough structure that offers excellent current density spread for consistent performance and efficient, low-loss energy transfer.

Cell-PLX's high-speed, robust laser weld attachment from collector plates to the cells enables efficient production processes, lower manufacturing costs, and high-volume operations. The thin and light interconnect solution fits into tight spaces and serves weight constraints, while also being extremely robust.

Customizable to fit tight spaces and meet weight constraints, Cell-PLX is further enhanced by the company's “U-Turn” technology, which addresses the tendency for EV batteries to develop hot spots within the current flows across collector plates. U-Turn technology mitigates internal hot-spot issues by ensuring uniform distribution of current throughout the entire battery module, reducing stress on the individual cells.

U-Turn enables optimal battery performance and increases EV range, improves battery lifespan, and boosts performance, leveraging precision, high-volume manufacturing methods that ensure each metal plate has a consistent thickness, even for very large interconnects.