Check out our Sensors Converge 2023 coverage.

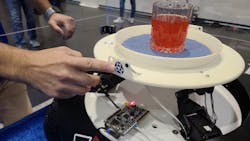

Ok, TDK doesn’t build robots, but it does provide a wide range of sensors and other electronic devices that will be found on just about any robot. Anson Yeganegi, Director, System Solutions at TDK, gave me a demo of the company’s delivery robot (Fig. 1) that takes advantage of 10 of its sensor systems.

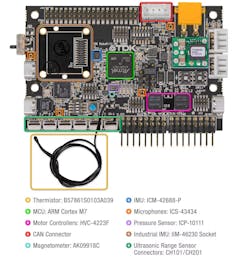

The brains of the system are hidden inside and include an NVIDIA Jetson, which is a popular host for robot developers. It typically works with a sensor integration device like TDK’s RoboKit 1 (Fig. 2). Eight of the sensors in the robot are part of the kit:

- ICM-42688-P 6-axis inertial measurement unit (IMU)

- ICS-43434 digital I²S microphone (x4)

- ICP-10111 barometric pressure sensor

- CH-101/201 time-of-flight (ToF) modules (x9) connected via flex cable

- IIM-46230 industrial IMU module connected via flex cable

- HVC4223F embedded motor controller

- AK09918C AKM magnetometer

- Temperature sensor

The board includes a SAME70Q21B Cortex-M7-based microcontroller. It includes software that supports obstacle detection, floor-type detection, cliff detection, and dynamic heading detection. It provides sensor and motor-control support to the Jetson host, which handles high level navigation and planning.

TDK offers more kinds of sensors and electronic devices (Fig. 3) beyond those used in the RoboKit1 and in the demo. Many will find homes in similar applications or other robot designs.

A good portion of the sensors in the RoboKit1 are mounted on the printed circuit board, but others are connected via cable, allowing them to placed elsewhere on the robot like the ToF sensor (Fig. 4).

The robot demo does a great job of highlighting the array of sensors currently utilized on robots. The days of basic bump sensors are long gone—more sensors are now needed to address the more robust support in high-complexity environments.

Check out more videos from our Sensors Converge 2023 coverage.