Members can download this article in PDF format.

What you’ll learn:

- The functional capabilities of the SAE J1772 Type 1/2 EV charging interface.

- How the Combined Charging System (CCS) specification adds dc fast-charge capabilities to the J1772 system.

- The signaling and control protocols that support J1772 and CCS interfaces.

The broad adoption of electric vehicles (EVs) depends as nearly as much on the driver’s ability to conveniently access public charging stations as the cost and quality of the vehicles themselves. The success of public networks, in turn, depends on the adoption of a common charging interface that can be used by virtually any EV.

Tesla overcame this problem by aggressively deploying its own fleet of chargers with its own proprietary interface1 throughout the U.S. Meanwhile, other EV manufacturers (and charging services) in the North American market experimented with several competing technologies before finally adopting charging interfaces based on some variant of the SAE J17722,3 standard, or its dc-capable variant, the Combined Charging System (CCS)4 (Fig. 1).

An Evolving Standard

The SAE's J1772 standard defines the physical, electrical, communication protocol, and performance requirements for the EV conductive charge system and coupler that supplies ac power to the vehicle's onboard charger (OBC). It subsequently converts the ac power to the dc voltage needed to charge the battery.

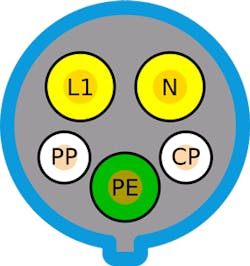

J1772 includes the spec for the commonly used J plug or Type 1 connector. Since its initial adoption in 2001, it has undergone several upgrades to its capabilities and form factor, leading to the adoption of the "Yakazi-style" five-pin circular connector that commonly used throughout North America, Europe, and Japan (Fig. 2).

In its latest revision, J1772 supports single-phase ac charging across a wide range of power levels, ranging from a 120-V connection provided by a 15-A household outlet (1.44 kW) to hardwired 240-V equipment that can deliver up to 19.2 kW (80 A @ 240 V). To ensure safety, the standard includes an interlock circuit that prevents the connector's pins from being energized when they’re not mated and keeps them that way until commanded by the vehicle.

The connector pinout is shown in Figure 3. In addition to the two receptacles for the ac power pins (L1 and L2) and the safety ground, aka protective earth (PE), the connector has two other pins that enable safe charging and provide a communication path between the vehicle and the charger.

The Proximity Pilot (PP) pin, also known as “plug present,” supports several functions. It serves to alert the vehicle's on-board charger (OBC) to the plug's presence and provides a signal to the vehicle's control system so that it can inhibit drivetrain movement while connected to the charging station. It’s also connected to a switch in the connector release button that’s used to initiate a controlled shutoff prior to actual disconnection of the charge power pins when charging is finished.

The fifth pin, known as the Control Pilot (CP), serves as a post-insertion signaling connection. It supports additional safety functions as well as two types of communications between the vehicle and the charging station. The safety mechanism includes a resistor and diode that sits between the CP and PE pins, which signals continuity by dropping the pilot voltage transmitted by the charging station from +12 to +9 V.

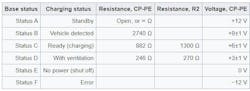

Until the CP-PE circuit is active, the live wires (L1 and L2) of a public charging station remain in their default inactive state (the exception being that the standard allows for a charging current as in Mode 1, i.e., up to 16 A @ 120 V ac). Once the CP-PE loop is closed, the charging station is now able to verify that the protective earth is present, allowing the vehicle to use the resistance between the CP and PE pins to request a particular charging mode (Fig. 4).

Once CP-PE continuity is detected, the charging station begins to transmit a variable pulse-width-modulated (PWM), 1-kHz square wave to the CP pin (±12.0 ± 0.4 V), which uses its duty cycle to inform the vehicle about the maximum charging current it can supply.

For example, if the vehicle sees a 16% PWM signal, the charger can supply 10 A maximum, 25% PWM indicates a 16 A maximum and 50% PWM indicates that up to 32 A is available. A PE signal with 90% PWM indicates that the charger can also support dc fast charging if the vehicle is equipped with a Combined Charging System (CCS) Combo connector. The basics of CCS will be discussed in the following section.

A Higher-Power Option

The Combined Charging System (CCS) Combo interface (Types 1 and 2) provides support for dc fast charging by adding two additional pins to the IEC 62196 standards5,6 for Type 1 (SAE J1772) and Type 27,8 connectors. In its present version, IEC 63196 can support charging rates of up to 350 kW at voltages up to 1200 V.

The CCS Type 1 connector (Fig. 5) is an extension of the SAE 1772 connector primarily found in North and Central America, Korea, and Taiwan.9,10 The Type 2 and Combo 2 style connectors (not discussed in this article) are primarily used in Europe, South America, South Africa, Australia, Arabia, India, Singapore, Taiwan, and Hong Kong.9 For both connector types, the two dc contacts were integrated in a manner that’s mechanically backward-compatible with regionally appropriate ac-only charging stations.

Although there are several different types of CCS connectors, they all use the same communication protocol to negotiate and control the charging process. CCS interfaces use two basic types of communication.

The first mode, known as Basic Signaling (BS), is the same PWM scheme transmitted over the CP contact used by J1772 ac charging systems for safety-related functions and, in the case of ac charging, to advertise the power level the available from the charging station. The only addition for the combo connector is that the station can transmit a pulse width of 5% that indicates the High Level Communication (HLC) protocol should be used.

The HLC protocol involves transmitting a modulated high-frequency signal over the CP contact (also known as power-line communication or PLC) based on the standard DIN SPEC 70121 and the ISO/IEC 15118 standard11 that can be used to transmit digital commands and information. In addition to controlling dc charging operations, HLC can be used to support other advanced services, such as vehicle-to-grid (V2G) load sharing.

The Inevitable Standards Battles

As with nearly every emerging technology, EV charging hasn’t been without its growing pains. Just about the time the CCS connector was becoming the widely accepted fast-charge interface for the North American market, Tesla announced it had opened up its formerly proprietary charging standard for use by all charging network operators and vehicle manufacturers.12

The design and specification files for the Tesla charging connector and charge port, now called the North American Charging Standard (NACS), are available are available for download. Tesla said that it’s actively working with relevant standards bodies to codify its charging connector as a public standard. While NACS technology does offer some potential advantages over CCS, it’s still unclear how many manufacturers will embrace it—and what kind of impact it will have on the EV industry.

Will tomorrow's EV drivers find themselves liberated from range anxiety, or obligated to lug around a trunk full of charging adapters to keep their batteries topped off? Stay tuned to learn more about this and other electrifying developments.

References

1. “Tesla Supercharger Stories 2017-2023,” Electrek.

2 – “SAE Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler Standard: J1772_201710,” Society for Automotive Engineering, October 13, 2017.

3. “The SAE J1772 Standard,” Wikipedia.

4. “Combined Charging System (CCS),” Wikipedia.

6. “The IEC 62196 Standard,” Wikipedia.

7. “Technicalities of Type 2 Connector for EV Charging – Part 1,” Engineers Academy, May 17, 2021.

8. “EV Type 2 Connector,” Wikipedia.

9. “CCS Combo Charging Standard Map: Where CCS1 And CCS2 Are Used,” Mark Kane, Inside EVs, February 15, 2021.

10. “International Electric Vehicle Plug Types,” Blink, 2021.

11. “ISO 15118-1:2019: Road vehicles — Vehicle to grid communication interface,” International Standards Organization (ISO).

12. “Tesla opens up its charging connector,” Umar Shakir, The Verge, November 21, 2022.

13. “Standards war? Things heat up between Tesla and CharIN,” Fred Lambert, Electrek, Dec 1 2022.