What you’ll learn:

- Specifics of non-electronic issues with waveguides.

- How nylon can be used to make waveguides via additive manufacturing.

- The virtues of a unique coating that metallizes the nylon waveguide for use.

While coaxial cables may be the preferred interconnect for microwave RF-energy transfers, they’re not the appropriate choice in many situations due to losses, power handling, or other attributes.

In these situations, the classic electromagnetic-energy waveguide, which predates coaxial cable by several decades, may be the better or only option. They’re almost lossless as well as “RF-tight” with respect to leaking energy or susceptibility to external interference. However, waveguides have their own issues with respect to weight as well as possible physical arrangements and configuration.

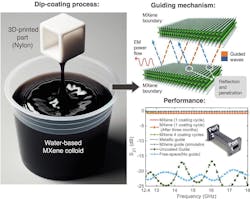

Now, a project team from Drexel University (Philadelphia, Pa.) and Canada’s University of British Columbia (Okangan) have developed a way to create lighter, more “articulate” waveguides using 3D additive-manufacturing techniques and a special conductive coating (Fig. 1).

3D-Printed Waveguides Using MXenes

While waveguides are typically made from metals like silver, brass, and copper, aluminum is the lighter-weight choice. Their 3D-printed products were created by combining conductive compounds called MXenes with a non-conductive polymer substrate such as nylon. These waveguides can be used as an alternative for metallic counterparts and have about one-tenth the weight.

The idea of using a lightweight polymer with an applied conductive surface to reduce weight isn’t new. Previous techniques such as electroless deposition of metals onto polymer substrates present challenges such as a restricted selection of metals/substrates, thermal stability of substrates and process temperature control, as well as adverse environmental effects.

Even metal paints, including those containing silver flakes, nanoparticles, or nanowires, have been explored. However, stabilizing metal particles—needed for solution processing such as dip coating—requires a complex mixture of stabilizers, additives, organic solvents, and binders, and these nonconductive ingredients have a detrimental impact on electrical conductivity.

What are MXenes?

Instead, the researchers used MXenes, an area where Drexel has done considerable material-science work. These two-dimensional transition metal carbides and nitrides (of which there are over 50 available formulations) have attracted significant attention due to their distinctive properties, including high electrical conductivity, ability to be processed as chemical solutions, thermal-shock stability, and other attractive attributes. MXenes form stable colloids in water and polar organic solvents without the need for additives or surfactants, for easy processing.

They have been used as an additive-free coating material that can be applied to a variety of substrates of any shape, such as foams, glass, and textiles. When properly applied, they conformally cover substrate surfaces. The first discovered, synthesized, and most studied MXene, designated as Ti3C2Tx, has undergone extensive synthesis optimization, with electrical conductivity measured as high as 24,000 siemens/cm.

The application of MXene is straightforward, requiring only the MXene and water. This simple scheme yields a highly conductive coating as soon as the water is evaporated at room temperature, during which MXene’s surface groups facilitate adhesion to the substrate.

The higher electrical conductivity allows for the use of thinner coatings, which are smooth and conformal. Those attributes are especially critical for microwave wavelength, as tiny surface perturbations and ripples have detrimental effects on energy propagation.

Waveguide Fabrication

They chose the commercially available nylon PA-12 as substrate and fabricated the waveguides using a selective laser sintering (SLS) printing method. They then applied the electrically conductive MXene from a water-based MXene (colloidal) solution to polymeric AM components (nylon channels) through a straightforward dip-coating process.

The researchers noted that dip coating is preferred over spray coating because it allows for the use of more concentrated (viscous) MXene solutions, can be used to coat narrow channels of complex shapes, and doesn’t require any special equipment. Their MXene coating added just a tenth of a gram to the overall weight of the component.

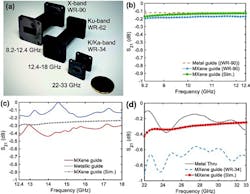

The microwave-associated functionalities were demonstrated at different power levels and in the frequency span of 8 to 33 GHz (Fig. 2).

The MXene waveguides performed nearly as well as their aluminum counterparts, showing an 81% efficiency in guiding electromagnetic waves between two terminals after just one cycle of dip coating, a mere 2.3% drop-off from the performance of aluminum (Fig. 3). The researchers demonstrated that they could improve this transmission metric by varying coating layers or the size of MXene flakes—reaching a top transmission efficiency of 95%.

The work is detailed in their short-titled paper “MXene guides microwaves through 3D polymeric structures,” published in Materials Today. The project shows that MXene coatings supported on additively manufactured polymeric components can replace traditionally manufactured channels of traditional metal-based waveguides. The benefits of the method include not only weight and cost of manufacturing, but also the feasibility of creating complex 3D-printed shapes that are much more difficult to make with metal.

References

Drexel University, “MXenes”

Drexel University, “About MXenes”