Every automated system that tests electronic circuit boards, modules, or equipment needs one or more DC power supplies. DC supplies provide power to the device under test as well as test stimulus. For example, while most automotive electronics run at a nominal 12 VDC, the maximum input voltage may be as high as 27 VDC. Because this is so, some automotive standards require margin testing up to 27 VDC on a 12-VDC device. Necessities such as these determine power supply requirements.

Let’s take a look at other common power supply specifications that you need to consider when selecting a power supply for an automated test system.

Linear or Switching Supply?

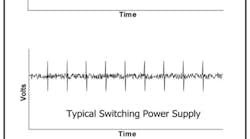

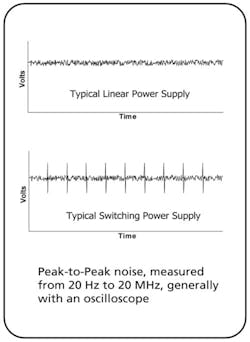

The first choice you must make when purchasing a DC power supply is whether to select a linear supply or switching supply. Linear power supplies offer low ripple and noise specifications and have fast transient behavior. The rms ripple can be measured up to 300 kHz with an rms voltmeter; peak-to-peak noise can be measured from 20 Hz to 20 MHz, generally with an oscilloscope. However, they are inefficient, generate a lot of heat, and are quite heavy. As a result, most engineers find them desirable only at lower output power levels (typically less than 500 W). Most linear DC power supplies are benchtop supplies.

One application for which a linear benchtop supply may be the best choice is when testing communications devices that have very sensitive discriminator or demodulator circuitry. To test the true performance of these units, we need to ensure that the DC power supply does not add any parasitic noise to the test setup, and because linear supplies generally have lower output ripple and noise than switching supplies, they are a better choice for this application (Figure 1).

Figure 1. Linear vs. Switching Supply Noise Profile

Linear supplies also are a good choice when power requirements are low. The main benefits of a switching supply are only relevant at higher output power levels. It is, therefore, less expensive to use linear DC power supplies in applications that do not require more than 100 W to 200 W per DC output channel.

At this point, it also is important to consider the total power output of all the DC channels in your system. If your system has four channels or less, and the power requirements are relatively low, a good solution would be to use four linear supplies in a 19-inch rack-mount kit.

If your system requires more output channels or higher output power, then using switching supplies is a better option. They provide higher power density than linear supplies. By using switching supplies, you can have 12 DC outputs, providing up to 4,000 W of power in the same rack mount. Switching supplies are easier to control than linear supplies and cost about the same per channel.

AMETEK Programmable Power provides a range of DC power supplies that offers high power density. The Sorensen ASD series, for example, supports up to 30 kW of power in a 3U package. The water-cooled packaging allows it to be used in environments that normally exclude air-cooled power supplies.

Even in applications where low ripple and noise output are required, switching supplies often are more than sufficient. Recent developments in power electronics, such as zero-switching, have improved the ripple and noise specifications of switching power supplies. When you also consider that switching power supplies are more flexible than linear supplies and provide higher power density, it becomes apparent they are the favored choice for all but a handful of applications.

Transient Response

Transient response is a measure of how well a supply copes with changes in current demand or how well the supply follows changes in the load impedance. This is an important specification for many applications.

When the output current demand decreases or increases significantly over a short period of time, the output voltage also may decrease or increase significantly. The power supply’s internal voltage-control loop will try to keep the output at the set voltage, but the response is not instantaneous.

To get a faster transient response, you sometimes have to settle for more ripple and noise. Within the programmable power supply, the trade-off is between the internal voltage control loop and the output filter. A large output filter will limit the ripple and noise but will make the supply slower to react to fast changing loads. A very fast internal voltage control loop will shorten transient response times but may cause overshoot or undershoot, which may damage the DUT.

Figure 2 shows that for a typical switch-mode supply, at a current change of 50% of maximum output current range, the DC output voltage will over- or undershoot not more than 2% of its set voltage and recover within 0.75% of the set voltage within less than 1 ms.

Figure 2. Typical Transient Response for a Switch-Mode Programmable DC Power Supply

A typical application example where transient response is important is mobile-phone testing. In this application, the DC power supply simulates the mobile phone’s internal battery. When it begins to transmit, the current rise is very quick.

This is not a problem for the internal phone battery, but for a programmable switching supply, it is a more difficult task. For this application, a linear supply would be a better choice than a switching supply because the power requirements are low, and the transient response of a linear supply is, in general, better than a switching supply.

Testing automotive relays and fuses is, however, another matter. For this application, the programmable DC power supplies must provide high currents at voltages up to 30 VDC, and typically, the power required is 5 kW to 10 kW. In this test, a large DC output voltage overshoot could damage the relay or fuse. To prevent this from happening, you want a supply that will control the DC output current instantaneously from zero to maximum output or from maximum to zero output.

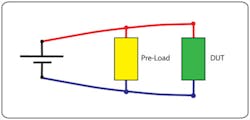

A practical technique to limit overshoot and undershoot is to use a pre-load (Figure 3). Putting a pre-load in parallel with the DUT and the DC output of the programmable power supply now will limit the percent current change, causing the DC voltage over- and undershoots to be significantly less. Imagine that 50% of the current travels through this additional pre-load and 50% through the DUT. When the DUT creates a 100% current demand step, the power supply only sees a 50% current demand change. For the power supply to manage 50% in current demand changes, instead of 100%, it is much easier and almost eliminates the effect of high voltage overshoots and any damage to the DUT. A simple inexpensive resistive load can be used in this case to function as a pre-load. Any ratio is fine. In other words, to obtain the transient response and overshoot specifications improvements, it does not really matter if this load absorbs 40%, 50%, or 60% of the current demand.

Figure 3. Pre-Load in Parallel with the DUT

A disadvantage of using a pre-load is that twice as much DC output current is required. Fortunately, additional power is relatively inexpensive. This makes using pre-load a much cheaper and more practical approach than specialized power supply subsystems for this application.

Slew Rate

The next specification to consider is the DC output voltage slew rate. To improve ripple and noise specifications, DC programmable power supplies have output filters that use large capacitors that store a lot of energy. It’s mainly the charge and discharge times of this filter, combined with the current demand of the DUT, that determine a supply’s voltage slew rate.

The DC output rise time for most AMETEK supplies is sufficiently fast for many applications. It is the DC output fall time that you must consider. The fall time depends not only on the internal LCR filter network at the DC output of the programmable power supply, but also on the connected DUT. If the current draw through the DUT is relatively low compared with the power-supply current capacity, it can take many seconds before the energy stored in the output capacitors leaks away through the DUT. If the DUT requires a minimum current demand of at least 60% of the power supply capability, the stored energy will leak away instantaneously, and the output voltage fall time will be the shortest. Nevertheless, in most cases, the DC output fall time will be two to three times slower than the DC output rise time.

One way to improve the DC output rise time is to choose a programmable power supply with a higher DC output range. For example, if the DUT is an automotive-related device and a 30-VDC power supply would cover all test applications, choose instead a 60-VDC programmable supply, but only use up to 30 VDC. The output capacitor for the 60-VDC supply will be much smaller than the output capacitor for the 30-VDC programmable supply to allow the voltage to rise from 0 V to full scale in the same amount of time for both supplies. In other words, when looking at the rise time in V/ms, the rise time for the 60-VDC power supply will be twice as fast.

A typical output current slew rate is 45 A/ms. AMETEK Programmable Power also makes some DC power supplies with an output current slew rate up to 400 A/ms to support solid-state laser applications. Faster current slew rates are possible by putting an electronic load in series with the power supply and using the electronic load as a current modulator. This combination allows for a current slew rate up to 6,000 A/ms.

Regulation and Stability

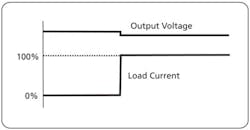

Another important specification of programmable power supplies is load regulation (Figure 4). This means some percent output voltage change from its set-point due to a change in the current demand of the DUT. Normally this effect should be very small (less then 0.01% of set output voltage).

Figure 4. Percent Change of Output Voltage as a Function of Load Change

Line regulation specifies the percent change of the DC output voltage or current as a function of AC input line voltage (Figure 5). This specification is important when the input line voltage is not stable.

Figure 5. Line Regulation

Stability is a measure of a supply’s long-term output voltage or current drift. A typical application is a magnet drive test in which the programmable supply works as a current source in constant-current mode. For this test, the user needs to be sure that the magnetic flux value is the same throughout the test. The supply must, therefore, set the DC output current to a specific value and maintain the value for the duration of the test. Stability is primarily specified in parts per million.

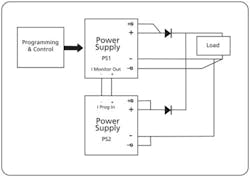

Parallel and Series Operation

If you need more output current than a single supply can provide, paralleling power supply outputs generally is the solution (Figure 6). AMETEK Programmable Power uses a dedicated control bus to connect its power supplies in parallel. By using this dedicated bus, the total performance of the units in parallel still meets the original specifications for just one single power supply. The system configures itself automatically, identifying which unit is the master and which units are the slaves. With fast transient DUTs, it is sometimes recommended to use protection-blocking diodes in the positive output line of each power supply.

Figure 6. Parallel Operation

When paralleling supplies in this way, you can use supplies that have different current ranges, but all of the supplies should have the same output voltage range. All manual or remote control is done through the master unit. Any sense lines are connected only to the master unit. Realize that the total current is the sum of the current values displayed on each individual power supply. Some advanced models can compute and display the total system current.

To supply a higher output voltage than is possible with a single supply, DC power supplies can be connected in series. All you have to do is to connect the positive terminal of one supply to the negative of another.

This is true, but there are some limitations. Every programmable power supply has voltage isolation specifications, one for the negative to chassis isolation and one for the positive to chassis isolation. Ensure these voltages are not exceeded.

Secondly, when operated in series, there are no master or slave units. This means that the power supplies need to be programmed individually. When using remote control for this, all interfaces must be galvanically isolated through opto-couplers. Most DC power supplies offer a number of isolated interfaces, including analog, RS-232, RS-485, and Ethernet.

Analog Programming

DC programmable power supplies typically provide a standard and isolated analog interface. Through the analog interface, a supply’s DC output voltage, current, and overvoltage protection can be set. These values are controlled by supplying a voltage signal or a current signal or by connecting a resistor to the analog input.

For example, you can use the analog output of a PLC to control the output voltage of a power supply. Or, you might use a thermistor to control the output of a supply. Also provided are voltage and current monitoring signal lines and control lines to enable or disable the power supply with millisecond reaction time.

Local and Remote Sensing

Many DC supplies can be configured for either local or remote sensing. For a more accurate output voltage setting, remote sensing should be used. In this mode, you sense the voltage where the power supply connects to the load. This method compensates for the voltage drop across the leads.

If sense lines are long, use shielded cables to avoid any interference being superimposed on the main DC output. Remote sensing often can compensate for a voltage drop much larger than specified. When using remote sensing, the transient response may be slower when the voltage drop across the power leads is high, but this usually is not a problem.

Constant-Current Mode

Although most supplies are used in constant-voltage mode, many applications call for using a DC power supply in constant-current mode. When operated in constant-current mode, some features or specifications are not applicable. For example, in constant-current mode, remote sensing is not a consideration. Neither are the output voltage set-point accuracy and resolution. What is important is accurate current control. Output voltage ripple and noise are not as important as output current ripple and noise.

In constant-current mode, the analog control can drive current changes at least 100 times faster than output voltage changes. The crossover from voltage to current mode is automatic. As soon as the current demand is larger than the set current limit, the DC power supply regulates its voltage down to match the set current limit and keeps the output current constant.

Inrush Current

For some applications, inrush current is a major consideration. Inrush current is the instantaneous input current drawn by an electrical device when first turned on. Some loads, such as electric motors and power converters, draw high inrush currents. A power supply may need to be sized for the inrush current.

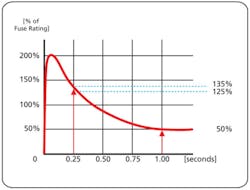

Digital Control and Measurement

In general, the output voltage and current of a programmable supply are set most accurately, with the highest resolution, through its digital interface. As mentioned earlier, DC supplies typically offer many different interfaces, including RS-232, RS-485, USB, GPIB, Modbus-TCP, Modbus-RTU, and Ethernet. Figure 7 shows a fast-output current profile created through sequence programming in support of a fuse rating test.

Figure 7. Digital Programming

In addition to the hardware, most DC power supply companies also provide the software you need to integrate your DC supply into your system. For example, AMETEK offers IVI drivers with each supply, and the supplies are programmed using standard SCPI commands. This makes system programming and system integration much simpler.

Accessories and Support

The availability of accessories also could be an important consideration in your choice of power supply. For example, if you plan to rack-mount the power supply, verify that one is available for your supply. Purchasing an off-the-shelf rack-mount kit is always less expensive than making one yourself.

In conclusion, when selecting a DC programmable power supply, there are many parameters to consider. Electrical specifications are perhaps the most important, but you also need to consider the form factor, control needs, and even what accessories are available. By taking all of these into account, you’ll make the best choice for your application.

About the Author

Bill Martin is the applications engineering supervisor with AMETEK Programmable Power. Prior to joining the company in 1992, he held several engineering positions with General Dynamics. Martin earned a bachelor’s degree in electrical engineering from Arizona State University.