This article is part of the TechXchange: LIDAR Technology

For autonomous vehicles (AVs), LiDAR (light detection and ranging) is an essential technology to recognize and detect surrounding objects. But current LiDAR technology costs hundreds if not thousands of dollars, weighs around one kilogram, and consumes several watts of power.

Researchers at KTH Royal Institute of Technology in Stockholm, Sweden created a cheaper, lighter and more efficient LiDAR technology that could pave the way for smaller systems targeting autonomous vehicles. Carlos Errando-Herranz, a postdoctoral researcher in the Division of Micro and Nanosystems, along with colleagues Nicolas Le Thomas and Kristinn B. Gylafson, writing in the journal Optics Letters (a publication of the Optical Society of America), say their new version of LiDAR would cost about $10(USD) each given large production volumes, weigh a few grams (including peripheral equipment), and consume some 100 mW.

Specifically, KTH researchers took aim at a key component of LiDAR—optical beamsteering—which is the dynamic pointing or scanning of such beams. Traditionally, optical beamsteering systems use electrical motors to tilt mirrors and scan a laser beam over a certain area.

Integrated photonics approaches to beamsteering—for example, integrating lasers, modulators, detectors, and filters on a single chip much like electronic integrated circuits—have focused on optical phased arrays. An optical phased array, which is similar in approach to phased-array antennas in radio wave or microwave technology, consists of an array of coherent emitters. Controlling these emitters using waveguide phase shifters to tune the output beam angle permits tight control over the beam shape and direction, with very high angular beam resolution resulting in accurate LiDAR measurements.

However, the commonly used optic phase shifters have high power consumption, generated by the need for one phase shifter per emitter, requiring hundreds of devices packed in a tight space. This has led to power consumption on the order of watts, which necessitates active cooling and limits the applications of this technology.

Manipulating MEMS

More recently, optical beamsteering systems have been scaled down by using microelectromechanical (MEMS) mirrors and gratings. It’s led to reduction of power consumption by an order of magnitude compared to traditional tuning methods (sub-microwatts for MEMS compared to 30 mW per thermo-optic phase shifter).

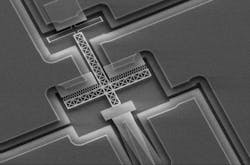

The KTH team demonstrated, for the first time, beamsteering by MEMS actuation of a suspended silicon photonic waveguide grating. The beamsteering device is based on changing the spacing between the teeth of a waveguide grating coupler using MEMS actuation.

The KTH miniaturized beam?steering device measures approximately 100 µm, and is best observed under a microscope, as shown here. (Source: Kristinn Glyfason, KTH)

The device is said to be capable of up to 5.6-degree beamsteering with 20-V actuation and power consumption below the microwatt level. It shows that the combination of MEMS with integrated photonics—integrating devices for beamsteering and optical signal processing, optical sources, and detectors with electrical processing and control—can provide the foundation for the next generation of power-efficient optical beamsteering systems. The power consumption of the demonstration unit, according to the researchers’ report, is more than five orders of magnitude lower than previous tuning methods.

“A traditional LiDAR is based on mounting an array of lasers on a rotating tower, like the Velodyne puck,” says Kristinn B. Gylfason, Associate Professor at KTH. “Our approach to LiDAR is based on integrated micro-opto-mechanics, where we have built a tunable grating into the surface of a silicon chip. By modifying the grating period, we decide in which direction the beam should sweep.”

The authors conclude: “Integrated thermo-optic phased-array systems have at least five orders of magnitude (limited by measurement, seven orders of magnitude based on our estimate) higher power consumption than our device, and suffers from thermal crosstalk problems, which our technology inherently avoids.”

Further miniaturization, the researchers say, has the potential to provide smaller, lighter, and less power-consuming beamsteering at a low cost—features that are required for the continued success of optical beam steering technologies in LiDAR. “We use the same production techniques as for manufacturing accelerometers and gyroscopes for smartphones,” says Errando-Herranz. “This means the costs can be really low on large volumes.”

Check out more content from the TechXchange: LIDAR Technology

>> Website Resources

.. >> Library: TechXchange

.. .. >> TechXchange: LIDAR Technology