Members can download this article in PDF format.

What you’ll learn:

- Gain insights into the changing role of NAND flash storage in modern automotive systems, from predictive maintenance to data-centric functionalities.

- Explore the specific NAND flash storage form factors crucial for various automotive applications, including ADAS, telematics, and infotainment.

- Understand the challenges and quality standards associated with qualifying SSDs for automotive use as well as the key design considerations for robust and reliable memory solutions in vehicles.

In the past, automotive systems generated data mainly for predictive maintenance. Sensors would detect parts that were failing or need attention and alert the driver for proper action to be taken. As autonomous driving continues to advance, today’s vehicles are becoming smarter as they transform into hubs of information, entertainment, and communication that generate, receive, and send huge amounts of data.

Automotive Systems: What NAND Flash Storage Form Factors Do They Need?

All of these advances in automotive technology are driving modern vehicles to evolve into mobile data centers, with specific applications requiring specialized memory and data-storage solutions.

Automotive/electric-vehicle systems can be roughly categorized into four main categories:

Vehicle controls

Common advanced driver-assistance systems (ADAS) technologies enable vehicles to perform certain functions autonomously or with little to no human intervention. For example, adaptive cruise control, automatic electronic braking, lane departure warning, self-parking, forward and rear collision warning, and driver drowsiness detection enhance vehicle systems for safer and better driving to reduce road fatalities by minimizing human error.

With the help of these technologies, certain controls may be performed automatically, with the driver acting as a monitor and intervening only when needed. Self-aware vehicles equipped with driver management systems (DMS) can now provide an understanding of the driver’s state in real-time and make instant decisions based on situational insight to ensure safety.

Telematics

A fusion of telecommunications and informatics, telematics refers to the collection and transmission of data on vehicle use to create solutions and diagnostics for maintenance, servicing, fleet management, and more.

In-vehicle infotainment (IVI)

Refers to vehicle systems used to deliver information and audio/video entertainment for both driver and passengers while on the road. IVI systems are integrated monitoring and control systems that improve the driving experience, as well as enhance comfort and safety. Typical features include smartphone integration, high-resolution touchscreen monitors, voice recognition, and backseat displays.

Navigation

Navigation systems provide maps and directions to help drivers reach their destination without having to use their phones.

These categories are just some of the many systems within a modern vehicle that run applications requiring different types of memory. Data-storage solutions used for specific applications may vary.

Below are common NAND flash storage form factors and corresponding applications where they are typically used (Fig. 1).

- e.MMC is widely used in ADAS, light detection and ranging (LiDAR), and telematics. Removable storage media like SD and microSD are often utilized in map and navigation systems or dashboard cameras.

- Ball-grid-array solid-state drives (BGA SSDs) are similar to e.MMC in terms of usage scenarios, but they’re typically preferred for applications that need better performance and larger capacities.

- Other SSD form factors, such as NVMe M.2 2280, are used mostly in IVI, data logging, and applications that require high performance. These will be the main focus of this article.

Automotive Quality Standards for SSDs

Numerous standards define specifications and features of SSDs built for automotive use. These include quality management, environmental requirements, interface parameters, and more – all of which aim to standardize the assessment criteria and global certification systems.

These massive and complex quality standards cover a range of areas, from quality management and supplier management to qualification items and flows. They offer guidance as a whole, but when it comes to individual products, they may not be fully applicable with regards to qualifications.

Key standards include:

- Automotive Electronics Council: AEC-Q100 — “Failure Mechanism Based Stress Test Qualification for Integrated Circuits” and AEC-Q104 — “Failure Mechanism Based Stress Test Qualification For Multichip Modules (MCM) In Automotive Applications”

- International Automotive Task Force: The IATF 16949 establishes the requirements for a quality management system (QMS) for the automotive sector. “This standard defines the requirements for a quality management system for organizations in the automotive industry, including automotive production, service and/or accessory parts organizations.”

- Automotive Software Process Improvement Capability dEtermination (ASPICE): This is “intended for use when performing conformant assessments of the process capability on the development of embedded automotive systems. It was developed in accordance with the requirements of ISO/IEC 33004.”

- International Organization for Standardization (ISO): The ISO/TS 16949 “defines the quality management system requirements for the design and development, production, and, when relevant, installation and service of automotive-related products.” Other ISO standards include ISO 26262/14001/9000/9001.

- VDA: “The Quality Management Centre (QMC) in the German Association of the Automotive Industry e.V. (VDA) is dedicated to the development of methods and systems of quality management systems for the automotive industry.”

- JEDEC: The JESD312 standard “standard defines the specifications of interface parameters, signaling protocols, environmental requirements, packaging, and other features for a solid-state drive (SSD) targeted primarily at automotive applications.”

Automotive SSD Qualification Challenges

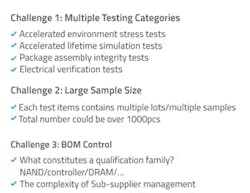

In-vehicle electronics is becoming more complex, thus requiring strict quality standards such as the ones mentioned above to make sure that components don’t fail (Fig. 2).

Qualifying SSDs for automotive use come with several challenges, such as those listed below, as they make automotive qualification resource/time-consuming:

Multiple testing categories

AEC-Q100/104, for example, has close to 50 testing items designed to make sure that the SSDs survive the harsh automotive environment during the product lifetime. They’re mainly categorized as Environmental, Mechanical, Electrical, and Others: Electrostatic Discharge/Electromagnetic Compatibility/Latch-Up (ESD/EMC/LU)

Large sample size is required

Sample size must be large enough to ensure that the data is statistically valid. AEC-Q100 and AEC-Q104 for example, specifies varying sample size requirements depending on the stress items to be tested, such as Temperature Cycling, Power Temperature Cycling, High Temperature Storage Life, and more. The challenge is how to strike a balance between qualification feasibility and reliability coverage.

While it’s ideal to include wider testing coverage on more drives, resources and time devoted to the testing may be constrained.

Imagine, for example, if an application requires 4-TB NVMe M.2 22110. Thousands of samples may need to be plugged into numerous chambers for various tests. It’s costly and resource/time consuming.

Therefore, feasible sample size and lots and testing will have to discussed and agreed upon between SSD supplier and the automotive system designer to guarantee sufficient testing coverage.

Strict BOM control

Another challenge when conducting automotive qualification is to consider what constitutes a qualification family. This might be more complicated, especially with SSDs, which may have lots of other passive components apart from controller, NAND, and DRAM. What components or bill of materials (BOM) need to be locked in before qualification? BOM control itself is a challenge. Sub-supplier management based on IATF 16949 is also a challenge. These all need to be considered.

Major SSD Design Challenges and Considerations

Aside from SSD qualification challenges, major design challenges must also be considered for SSDs to be considered qualified for automotive use.

Design Challenge #1: Environment-dependent adversities such as temperature extremes, humidity, air pollution, altitude, and mechanical shock and vibration.

ATP uses stringent qualification tests such as those defined in AEC-Q100/104 to ensure product robustness. These include:

- Accelerated environment stress tests: temperature humidity bias, temperature cycling; temperature storage life

- Accelerated lifetime simulation tests: high-temperature operating life, early life failure rates, endurance and data-retention tests

- Mechanical tests: shock and vibration, solderability assessment

Design considerations/suggestions: Due to the complexity and multiple components used on SSD drives, performing such tests are challenging, and extra caution should go into solderability. Stringent temperature cycle combined with shock and vibration together should be conducted on the same samples, instead of on separate groups of samples. Inter-circuit testing, drive function testing, and X-ray check should be inserted in between and after temperature cycle testing to guarantee solderability.

Other SSD design considerations to include are anti-sulfur resistors, conformal coating for humidity and pollutants, and component derating for use.

Design Challenge #2: High sustained read/write performance in high temperatures. High-performance SSDs are prone to heat-generation problems. To protect the drive itself, thermal throttling is activated when a certain temperature is reached, which could affect SSD performance.

Design considerations/suggestions: For effective heat dissipation without compromising performance, heatsink design or active cooling will have to be included in the design. The design and the choice of heatsink may depend on the automotive system design, considering limitations on heatsink dimensions, system airflow, and active cooling.

Assessing and optimizing SSD performance under specific environment conditions is crucial. Therefore, joint validation between SSD supplier and system designer is also crucial (Fig. 3).

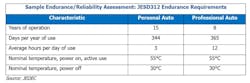

Design Challenge #3: Endurance and reliability assessments (see table). The endurance/reliability requirements can be vastly different between user behaviors, between personal vehicle and commercial vehicle, and numerous other factors and usage scenarios. Hence, design considerations are totally different.

In assessing automotive lifespan for personal vehicle use, the main consideration is longer years of operation while professional auto usage consideration focuses more on higher frequency with longer total operating hours.

The prime concern of SSD drives is NAND quality. SSD endurance rating and reliability are influenced by temperature, and the drive writes per day (DWPD) or total bytes written (TBW) rating decreases in the higher temperature range.

To guarantee better endurance, adopting single-level-cell (SLC) NAND or pseudo SLC (pSLC) mode triple-level-cell (TLC) NAND may appear to be a better choice. They have intrinsically better reliability and better sustained performance.

Another temperature-dependent factor is environment temperature variance during operation. As previously mentioned, this is related to heat-dissipation design of the SSD and the system. Close collaboration between SSD supplier and automotive system designer is required.

Design considerations/suggestions: To guarantee better endurance, adopting SLC NAND or pSLC mode for TLC NAND with large overprovisioning (OP) will guarantee sufficient endurance. That’s because they have intrinsically better reliability and better sustained performance compared with native TLC NAND.

As mentioned in the above section, environment temperature variance during operation is an important consideration. For effective heat dissipation, adopting an SSD heatsink design and active cooling for the system may be required. To accomplish this, the SSD supplier and automotive system designer should collaborate closely.

Other Reliability Considerations

What constitutes a qualification family? For automotive qualification, component usage needs to be locked. Key components are easy to define. These include the SSD controller, NAND, and substrate. However, SSD components are complex, including many other ICs and passive components. How can total SSD reliability be guaranteed?

Design considerations/suggestions:

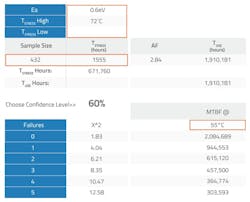

Component derating for all components used on an SSD should be assessed to guarantee enough design guard band.

For reliability assessment, mean time between failure (MTBF) is normally used to gauge reliability. However, the common practice of using software such as Telcordia to predict reliability only gives theoretical, not actual, value. Therefore, we suggest conducting a reliability demonstration test (RDT) to calculate the actual MTBF based on actual application temperature and workloads. In other words, enough SSDs need to be tested with application-defined workloads in elevated temperature for accelerating RDT for MTBF calculation (Fig. 4).

Other Reliability Considerations

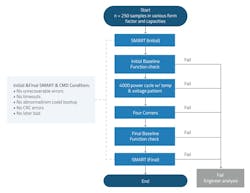

Another aspect of reliability testing is the simulation of extreme usage cases. By subjecting the SSD to temperature extremes and voltage variance, combined with sudden power off, product reliability is validated when usage scenarios become mission-critical. Imagine your car power suddenly going off and the SSD doesn’t respond when the power switches back on. Such testing includes:

Four-corner testing: A method of ensuring that SSDs function reliably and can read/write without data miscompare. It’s based on the testing matrix of temperature and voltage extremes to better simulate the automotive environment (Fig. 5).

Power cycling/sudden power-off recovery testing: The use of power-loss protection capacitors should be adopted to enhance robustness and enable the SSD to cope with sudden power loss. The power reserve may be able to sustain the drive to complete the last operation so that no data-in-flight is lost (Fig. 6).

NAND Endurance: JEDEC Enterprise Workload, P/E Cycles

NAND endurance is typically expressed in DWPD or TBW, which represents the total amount of data that can be written on an SSD within its lifetime. It depends greatly on applications and workloads being run on the SSD. ATP uses JEDEC Enterprise Workloads (JESD219) to test automotive SSD endurance and retention, and performs testing based on design environment and temperature to check the rated lifespan of the NAND flash and beyond.

P/E cycle reflects the lifetime of an SSD based on the number of program/erase cycles that the NAND can endure. ATP performs P/E cycle testing until the rated end of life and even beyond to check if there’s any performance degradation and if the retention is okay. This tests if the SSD can meet the TBW rating on the datasheet. At 10%, 100%, and 120% P/E cycles, data retention is checked.

Other information that can be derived from the tests include whether there are no later bad blocks generated during the test or if wear leveling is acceptable.

Conclusion

As vehicles increasingly become mobile data centers that receive, process, and send massive amounts of data, NAND flash storage usage is ramping up in automotive systems. Different form factors usually cater to fulfill different requirements of specific applications.

To determine whether SSDs are fit for the rigorous demands of automotive systems, several testing standards are already in place. Currently, though, no automotive quality standards are fully acceptable to all form factors.

Ensuring reliability is important, but multiple testing categories, large sampling sizes, and strict BOM control make automotive qualification resource-/time-consuming. The challenge faced by SSD manufacturers like ATP Electronics is how to strike a balance between qualification feasibility and reliability coverage.

While various testing methods are available, it’s also difficult to assess an automotive SSD’s lifespan as it’s temperature-dependent as well as user-dependent.

To ensure automotive qualification and prove the SSD’s rated endurance and retention, ATP performs rigid testing based on internationally recognized standards. It offers robust SSDs to meet the strict requirements as well as the diverse workloads and challenging operating scenarios of automotive applications. Visit the company’s website for more information on its automotive-qualified SSDs.