This video/article is part of Dostal's Designs series in Ideas for Design and the TechXchange: Power Supply Design. You can also post a question.

Members can download this article in PDF format.

What you'll learn:

- Linear vs. switching surge stoppers.

- An input protection circuit featuring an LTC4380.

- Protection circuit design using a switching surge stopper.

Reliable industrial electronics often have protection circuits to head off any overvoltages on the supply lines and protect the electronics from damage. Overvoltages can arise when fast load changes occur on the power-supply line. Parasitic line inductance may result in high voltage spikes.

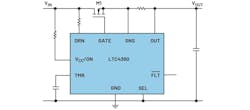

This issue can be addressed with an input protection circuit like that shown in Figure 1, which integrates an LTC4380 from Analog Devices. Power switch M1 is in the conductive path. If an overvoltage occurs at VIN, switch M1 is operated in the linear region. It causes M1 to behave as a resistor in the ohmic region, allowing VOUT to be regulated by the voltage drop across MOSFET M1.

In turn, it prevents the output voltage from rising to excessively high levels, thereby protecting downstream electronics. This method is effective within a certain time limit. The duration is determined by the permissible safe operating area (SOA) of switch M1. However, if the voltage drop across the power MOSFET remains high and the duration exceeds the limit, the MOSFET will heat up beyond its maximum temperature threshold and become damaged.

Integrated circuits such as the LTC4380 have built-in timers to protect against overvoltages. The amount of time that the MOSFET operates in the linear region in an overvoltage situation is set on the timer. This time is usually on the order of a few milliseconds or microseconds. Once the set time has elapsed, switch M1 is completely shut off. As a result, the switch is protected, but the power supply to the system also shuts off.

Integrating a Switching Surge Protector

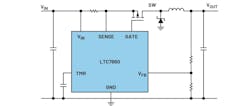

To ensure reliable operation and uninterrupted power supply to industrial electronics under all circumstances, it’s crucial to choose a solution that can tolerate overvoltage for extended periods. This includes considering fault scenarios such as incorrectly connected supply lines that may result in overvoltage. By selecting a solution that can handle these situations, the circuit can operate reliably and avoid disruptions to the supply voltage. This can be realized with a switching surge protector (Fig. 2).

In addition to the surge protector IC, the circuit uses an inductor and an external Schottky diode. Basically, a step-down (buck) switching regulator is operated as a protective circuit. However, this switching regulator only begins to work when the input voltage exceeds a set maximum value. Operation in this time period typically doesn’t have to be particularly power-efficient. A simple Schottky diode can be used as a flyback diode.

Figure 3 shows an input voltage response in blue. The normal input voltage is 16 V. At approximately 2 ms, an overvoltage reaching 40 V occurs. The change in output voltage over time is shown in red. For the duration of the VIN overvoltage, the switching DC-DC regulator is activated to regulate the output voltage to 16 V. The switching node voltage (at the node between the MOSFET, the Schottky diode, and the inductor) is shown in green.

An overvoltage protection circuit can thus be designed linearly as shown in Figure 1 or with a special switching (buck) DC-DC regulator like the LTC7860 in Figure 2. A simple step-down switching regulator isn’t suitable for this application because the N-channel MOSFET can’t be continuously on in this case.

Overvoltage protection circuits include both linear surge protectors and switching surge protector ICs. The latter allows for continuous operation of a circuit even during a lengthy overvoltage event. This means that the circuit to be powered is continuously protected and operational, even when overvoltages last a long time.

Give More Thought to Component Selection

More and more industrial and instrumentation applications require precision converters to accurately control and measure various processes. In addition, these end applications demand increased flexibility, reliability, and feature sets, while simultaneously reducing costs and board area. Component manufacturers are addressing these challenges and offering a number of products to address the needs of system designers for current and future designs.

As can be gleaned from this article, many different approaches can be taken to select the right components for precision applications, each offering their own associated drawbacks and benefits. As the accuracy of the system increases, more thought needs to be put into the selection of the right component to suit the application needs.