This article is part of the TechXchange: Critical Connections: Cables, Wires, Vias, and Busbars

Connector packages come in a variety of shapes and sizes. Whether the connectors are circular, backplane, or planar array, recent innovations in connector technology including contact systems, inserts, and more flexible designs are enhancing performance across the board. Regardless of the type of connector, application, or necessary specifications, materials and manufacturing processes play key roles in the connector’s performance within a given application.

Contact Systems

In many applications such as defense, industrial systems, oil field exploration, and tactical communications, interconnects must able to withstand extreme shock, vibration, and thermal dynamic conditions. A key design consideration for connectors within such applications is the contact system, which must be robust as well as flexible across various configurations and specifications.

While many traditional male-to-female contact systems do not support these demands, recent innovations do. For example, one design utilizes a spring probe pin/pad contact system where the spring probe pin resides in a plug-connector configuration. This particular design employs an internal clip mechanism that ensures proper contact engagement while also allowing the connector receptacle to house individual touch-pad contact areas, providing a highly effective electrical engagement connection point.

Such contact systems are often able to resolve misalignment issues. If misalignment occurs in traditional contact designs, even by as little as 0.005 in., pins can easily break. This results in a defective contact system and faulty connector, costing the manufacturer up to hundreds of dollars in some applications. As a result, we typically specify traditional pin-and-socket designs at a maximum of 500 cycles while other designs such as the spring probe system are capable of more than 5000 cycles.

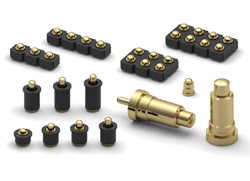

Contact system designs that are more forgiving in terms of alignment also generate more force than traditional pin-and-socket designs. In a spring probe system (Fig. 1), for example, contacts are pre-loaded, and force is generated immediately. This results in a much higher force at deflection. Also, because alignment is not as critical in this design, the contact system can generate a significant amount of hertzian force while maintaining signal integrity.

Additional benefits are also possible via enhancements to traditional male-to-female contact designs. For instance, taking male-to-female contacts and stacking them as single units and then over-molding the shell around the contact creates a simplified, cost-effective connector solution capable of combining signal and power in one design. One approach is to custom configure the contacts for each application and either terminate them to cable cores within the module or employ them as feed-through contacts to route power or signal to another module/cable in the stack.

Contact geometries can also be staggered within the stacked modules to meet the needs of specific applications. The modular design enables the addition of accessories or functions to the system simply by plugging in another module, eliminating the need to add a separate connector.

Further cost cuts are possible by completely machining the male contacts and integrating them into the star clip. By machining the contacts, tooling costs are significantly lower when compared to conventional connectors. Daisy-chaining power and signal in a cost-effective, streamlined approach while over-molding and sealing electrical connections for protection against fluid or water penetration, these designs afford significant advantages in numerous applications.

Insert and Filter Innovations

Other performance improvements come by way of enhancing the materials surrounding the contact. In doing so, many start within the housing and work their way out. For example, standard circular multi-pin connectors with positive locking and quick disconnect features often employ a rubber or plastic insert, suiting them for applications such as commercial and entertainment devices.

However, rubber and plastic inserts have temperature limitations, typically around 165°C. Merely altering the insert material or by utilizing metal hermetic seals rather than elastomeric inserts, we can achieve superior resistance to fuel oils, solvents, and elevated temperatures, significantly increasing the number of applications for which the connector is suitable.

Employing a ceramic insert, which is resistant to fire, with a rigidity that makes it less susceptible to vibration and breaking, can increase the connector’s capabilities from 165°C to more than 700°C. By the same token, high-temperature silicon grommets seal the connector wires against humidity and water penetration.

As an example, one particular high-temperature connector (Fig. 2) consists of machined nickel, gold-plated contacts with ceramic inserts.

Because of enhanced manufacturing processes including state-of-the-art molding, plating, and stamping, ceramic is now a moldable material, making it a viable solution for designs operating under extremely high temperatures. Once a connector achieves temperatures in the 700°C range, previously unattainable applications including mass transit and railway systems, geophysical, nuclear, and military are well within the designer’s reach.

Yet in some applications, ceramic isn’t always a good thing. While ceramic is ideally suited for high-temperature environments, extreme thermal shock and vibration can often result in cracked ceramic filters.

The planar array design, currently the industry standard for filter connectors, employs a block capacitor with plated through-holes that support feed-through, soldered-in contact. The planar array filters are ceramic-based and require a reliable electrical mating with the contact through a variety of soldering processes. However, a ceramic capacitor is susceptible to damage and cracking in such environments, leading to electrical failure and in turn requiring costly thermal shock screening and burn-in procedures to ensure its electrical performance integrity.

In response, connector manufacturers have developed alternative technologies to replace the fragile ceramic planar array block capacitor. One such filter technology relies on a patented state-of-the-art flexible circuit where individual chip capacitors surface-mount on a pad adjacent to the feed-through contact. Since the feed-through contacts do not solder directly to the capacitor, we eliminate the thermal stress points that impact performance in thermal shock and vibration.

Offering an alternative to standard ceramic planar arrays, such designs result in a very robust filter connector (Fig. 3) with superior mechanical performance and improved reliability while offering standard filtering capabilities including individual isolated pin filtering of high-frequency noise, built-in ground plane barriers in the connector inserts, and filtering at the face of system boxes.

In addition, since the flex assembly is significantly lighter in weight and less solder is required for the flex material, a connector weight reduction up to 15% is achievable. This flexibility maintains the same performance benefits as traditional ceramic filter capacitors while removing any need to retool a ceramic planar array.

Manufacturing processes also play a role in achieving filter technology innovations. Ceramic planar arrays require hand soldering or hand placement of solder rings prior to reflow oven soldering. These processing requirements lead to varying solder deposits. Manufacturing processes of alternative filter designs, such as those mentioned above, eliminate this significant source of processing variability through the use of newly developed, error-proof, robust solder application processes.

Conclusion

Materials and manufacturing processes play a significant role in the development of innovative connector technologies. Through the enhancement of existing connector packages or the development of entirely new designs, design engineers are afforded connectors capable of higher temperature ranges, increased shielding specifications, longer life cycles, and even hundreds of hours of salt spray testing due to their plating materials. As such, connector manufacturers are finding use for innovative designs in applications where they weren’t previously suitable or generally specified.

This article was updated on 9/18/23